Irregular helical multi-wedge belt and preparation method thereof

A multi-ribbed belt, irregular technology, applied in the direction of transmission belts, mechanical equipment, other household appliances, etc., can solve the problems of air pinch abnormal noise, short service life, cutting abnormal noise, etc., to reduce abnormal noise problems, improve life, Reduce the effect of running shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1,1

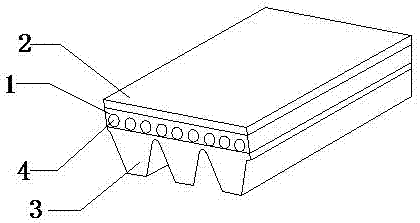

[0038] Embodiment 1, 1, composition structure of irregular helical V-ribbed belt

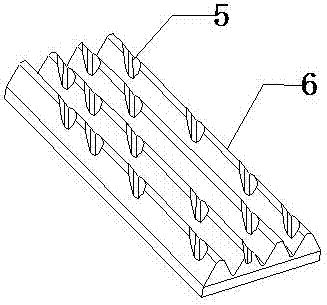

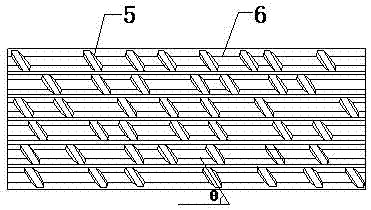

[0039] Such as Figure 1~2 As shown, an irregular helical V-ribbed belt includes a belt body 1, a belt back 2 on the outer surface of the belt body 1, and a plurality of wedge teeth 3 on the inner surface of the belt body 1, and the wedge teeth 3 are along the length direction of the belt body 1. Extending, on each wedge tooth 3 along the length direction of the belt body, there are slots 5 inclined in several directions, the spacing between the slots 5 is not equal, and the angle θ between the inclination direction of the slots 5 and the length direction of the belt is 45°. This included angle makes the irregular helical teeth on the V-ribbed belt more streamlined, and has a better effect on reducing the abnormal sound of cut-in and air-flow pinching when the belt is running. The groove depth of the tooth groove 5 is 1.5mm-2.0mm, and the groove width is 5mm-15mm.

[0040] A tensile layer 4 i...

Embodiment 2

[0072] Embodiment 2, 1, composition structure of irregular helical V-ribbed belt

[0073] Such as Figure 1~2 As shown, an irregular helical V-ribbed belt includes a belt body 1, a belt back 2 on the outer surface of the belt body 1, and a plurality of wedge teeth 3 on the inner surface of the belt body 1, and the wedge teeth 3 are along the length direction of the belt body 1. Extending, on each wedge tooth 3 along the length direction of the belt body, there are slots 5 inclined in several directions, the spacing between the slots 5 is not equal, and the angle θ between the inclination direction of the slots 5 and the length direction of the belt is 20°. This included angle makes the irregular helical teeth on the V-ribbed belt more streamlined, and has a better effect on reducing the abnormal sound of cut-in and air-flow pinching when the belt is running. The groove depth of the tooth groove 5 is 1.5mm-2.0mm, and the groove width is 5mm-15mm.

[0074] A tensile layer 4 i...

Embodiment 3~5

[0106] Except for the angle between the inclination direction of the tooth groove and the length direction of the belt body as shown in the table below, the rest of the operations are the same as in Example 1

[0107]

[0108] The irregular helical V-ribbed belt prepared in Examples 3-5 is tested for performance, and the test results are superior to those of no-toothed, straight-toothed and regular helical-toothed V-ribbed belts in terms of noise, fatigue life, and belt vibration , reached the performance requirements of the car V-belt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove depth | aaaaa | aaaaa |

| Groove width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap