Perforation shock absorber device

A shock absorber and through-hole technology, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling, etc., can solve the problems of unsatisfactory shock absorption effect, unsatisfactory shock absorption effect, and non-reusable use. To achieve the effect of simple structure, good shock absorption effect and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

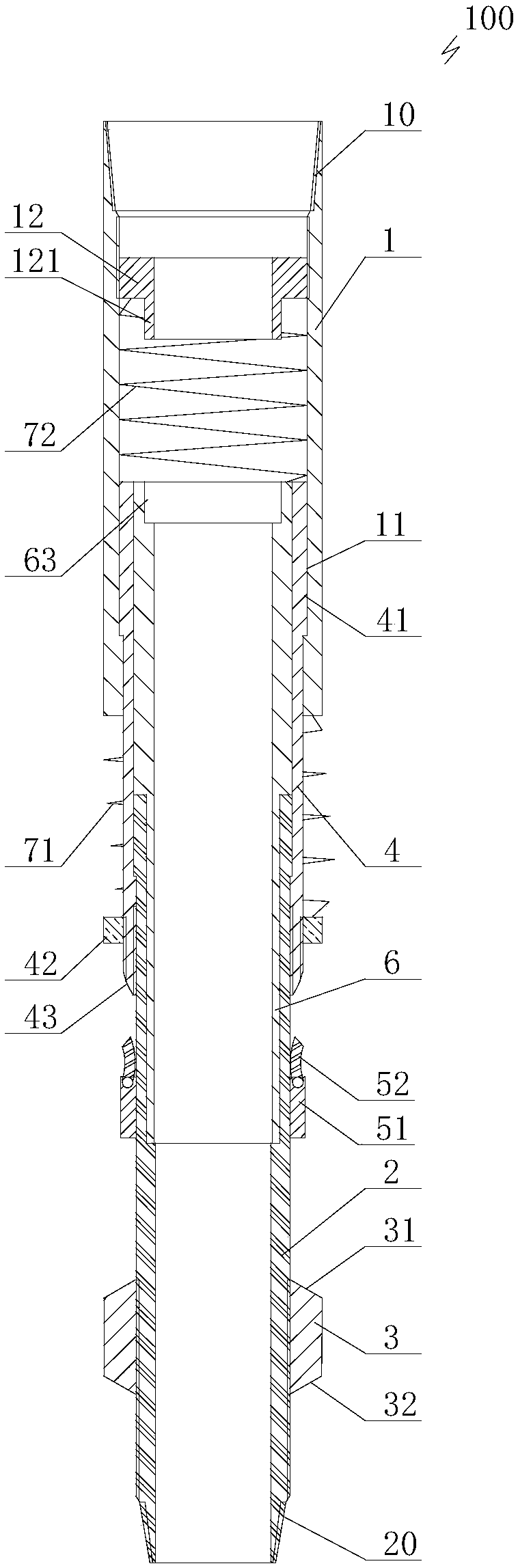

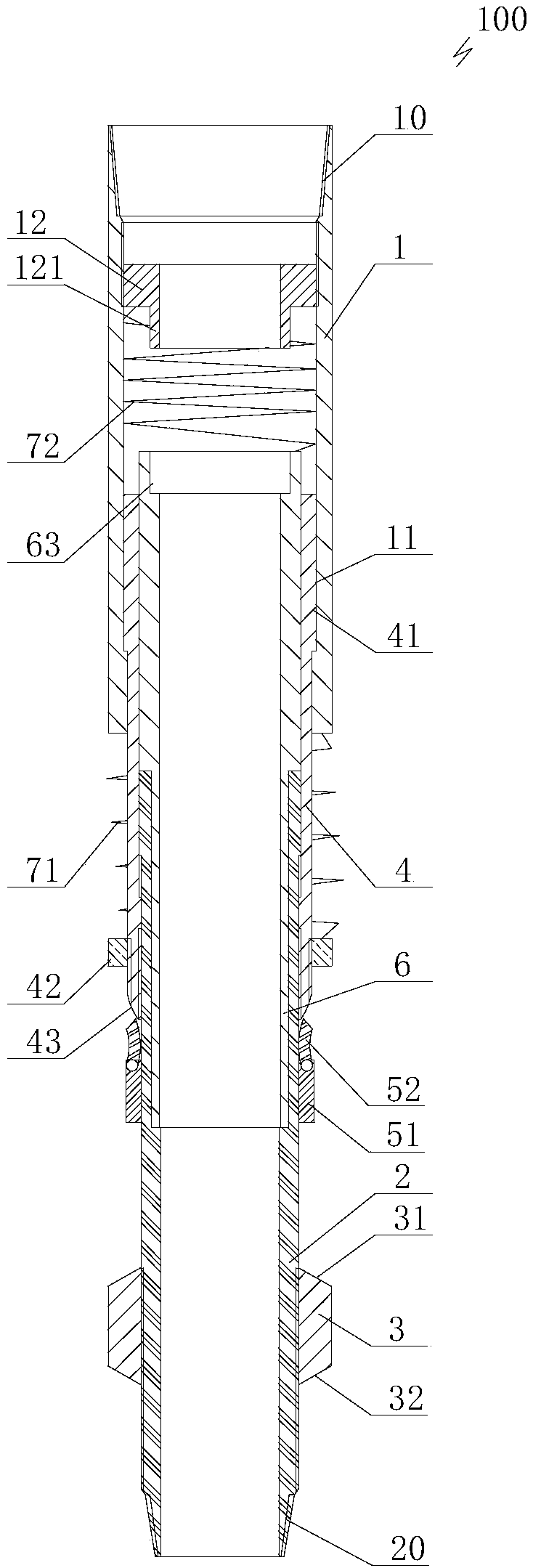

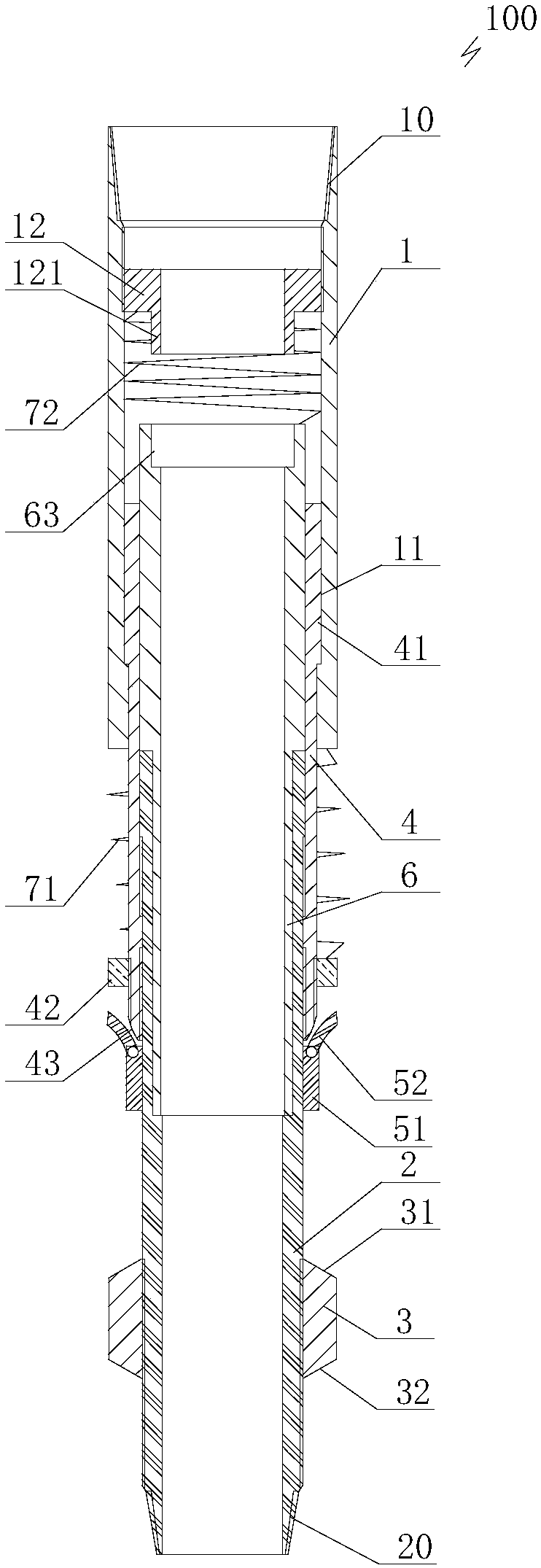

[0053] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0054] like Figure 1 to Figure 10 As shown, the present invention provides a perforation shock absorber device 100, including the top energy and the upper pipe string 91 (the perforation pipe string is separated into two parts, the upper pipe string 91 and the lower pipe string 92 by the perforation shock absorber device) The connected upper cylinder 1 and the lower cylinder 2 whose bottom can be connected with the lower pipe string 92. In this embodiment, the top of the inner wall of the upper cylinder 1 is provided with an internal taper threaded part 10 for connecting the upper pipe string 91. The bottom of the outer wall of the cylinder 2 is provided with an external taper thread part 20 for connecting the lower pipe string ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap