Shock absorption coupler structure

A technology of coupling and active disc, applied in the direction of coupling, elastic coupling, mechanical equipment, etc., can solve the problem of difficult to meet the requirements of use, the effect of improving vibration is limited, and the coupling cannot absorb the vibration energy of the motor and transmission and other problems, to achieve the effect of simple and reliable structure, excellent shock absorption performance, and impact mitigation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

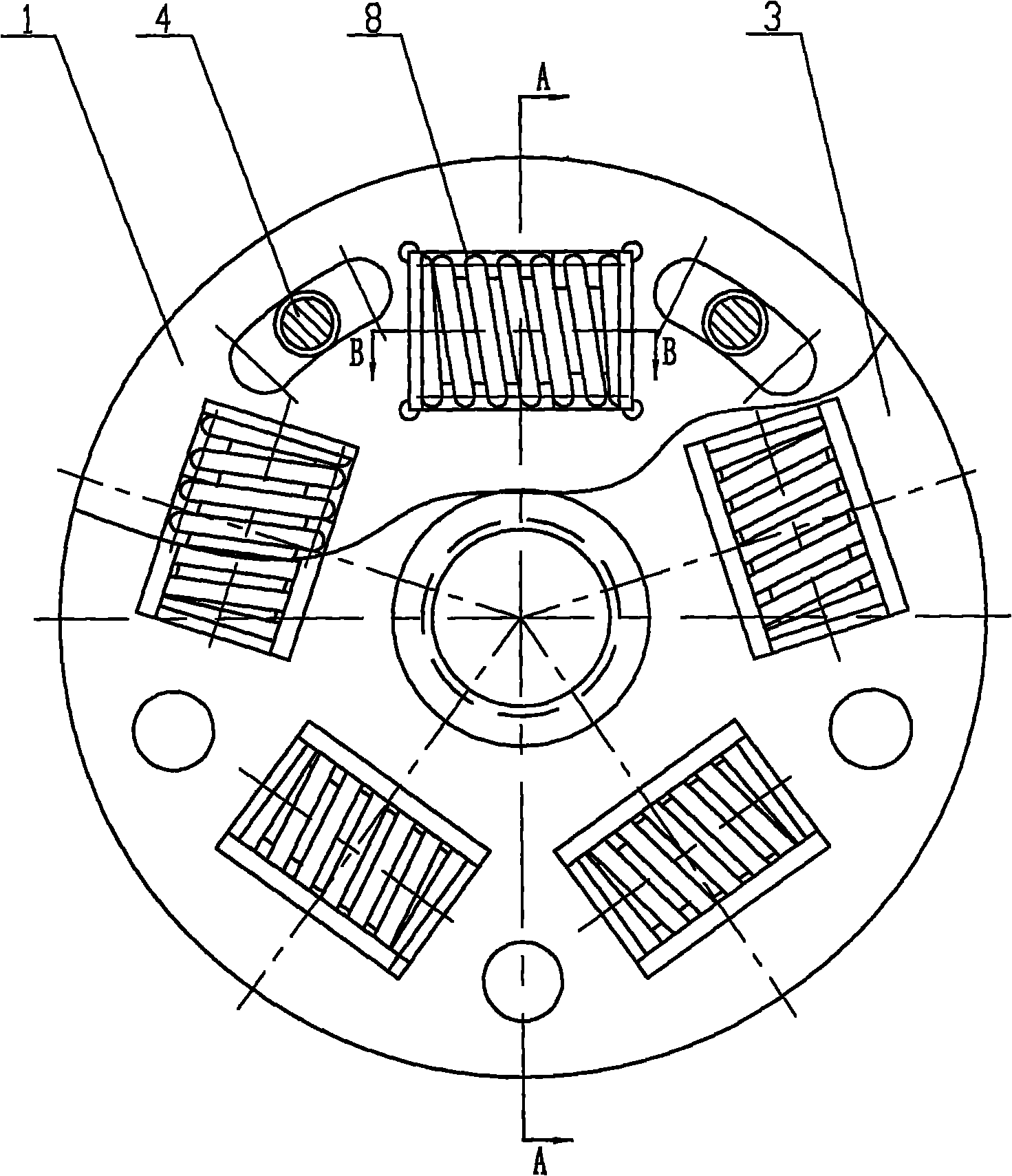

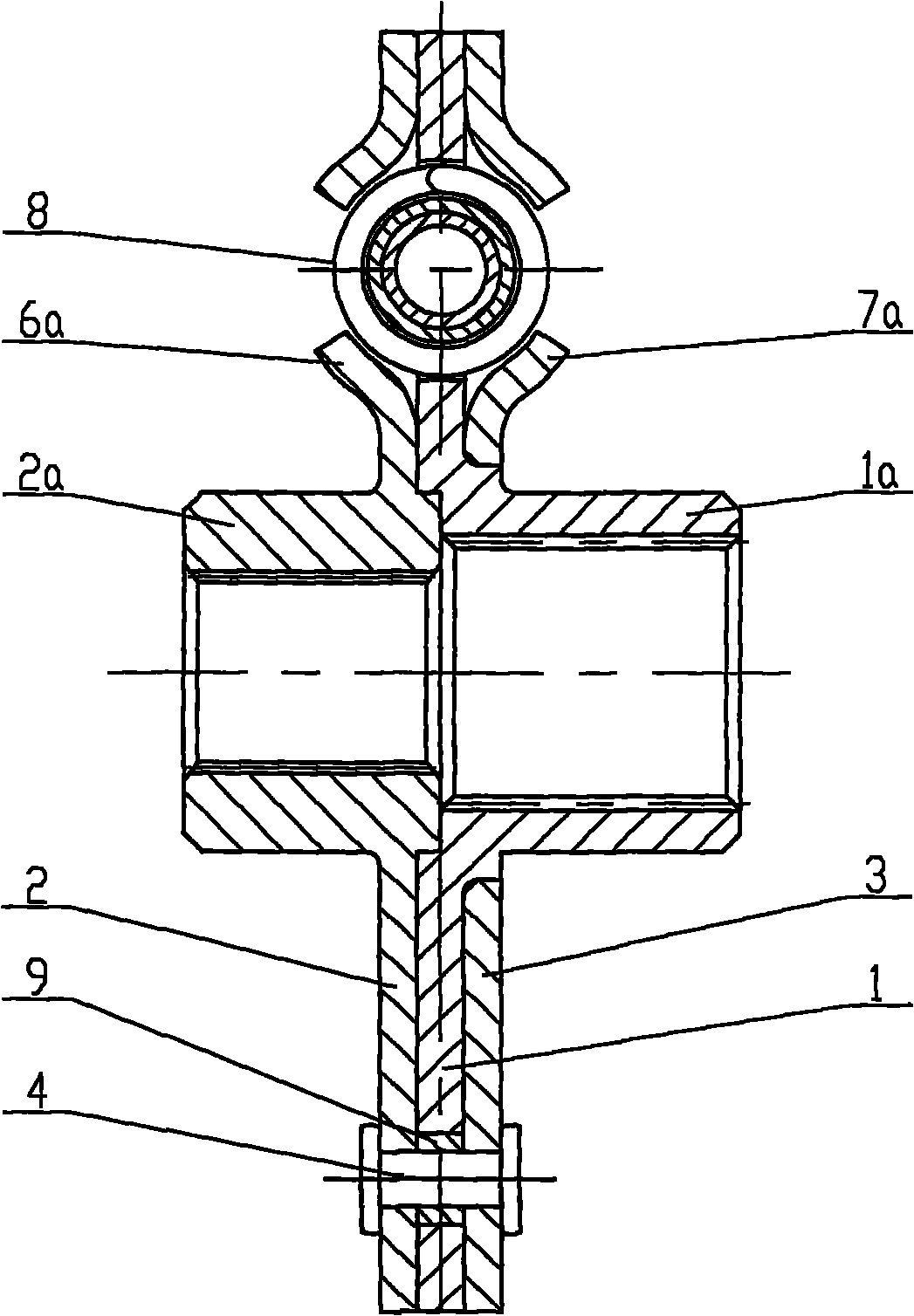

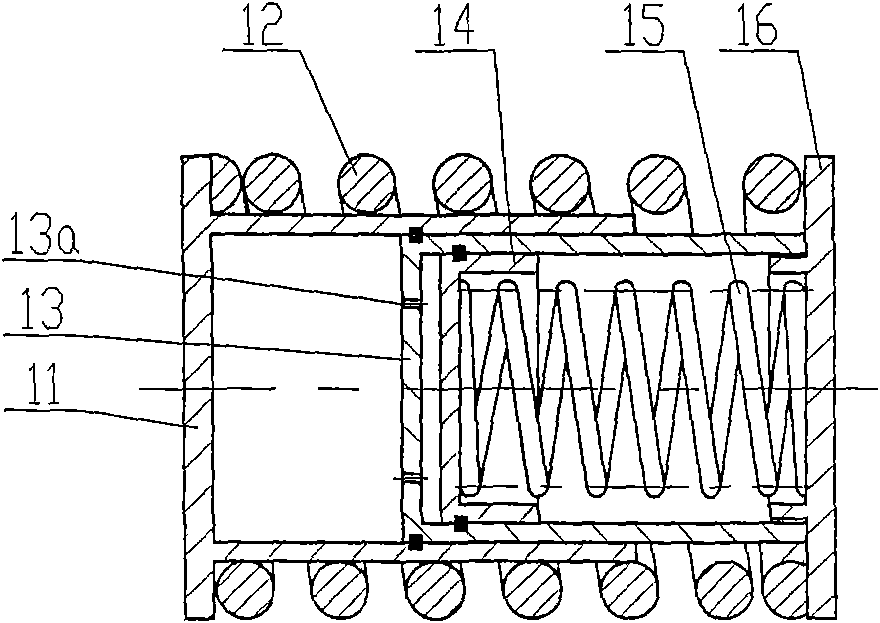

[0025] Such as figure 1 , Figure 4 , Figure 5 As shown, the present invention is made of driving disc 1, driven disc 2, pressure plate 3, rivet 4, shock absorber 8 and spacer 9 etc., wherein driving disc 1 is a disc structure, and the middle part of driving disc 1 is provided with A through hole, one side of the through hole is integrally formed with a first annular boss 1a, and the inner hole of the first annular boss 1a is a spline hole. The disc body of the drive disc 1 is provided with five arc-shaped holes 1b uniformly distributed along the circumference, and the center of the circle where each arc-shaped bar hole 1b is located is on the axis of the drive disc 1 . On the disc body of the driving disc 1, five first positioning holes 5 are evenly distributed on the circumference. A small round hole 10 is opened at the corner, and the small round hole...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap