Fan Frame of an Axial-Flow Fan

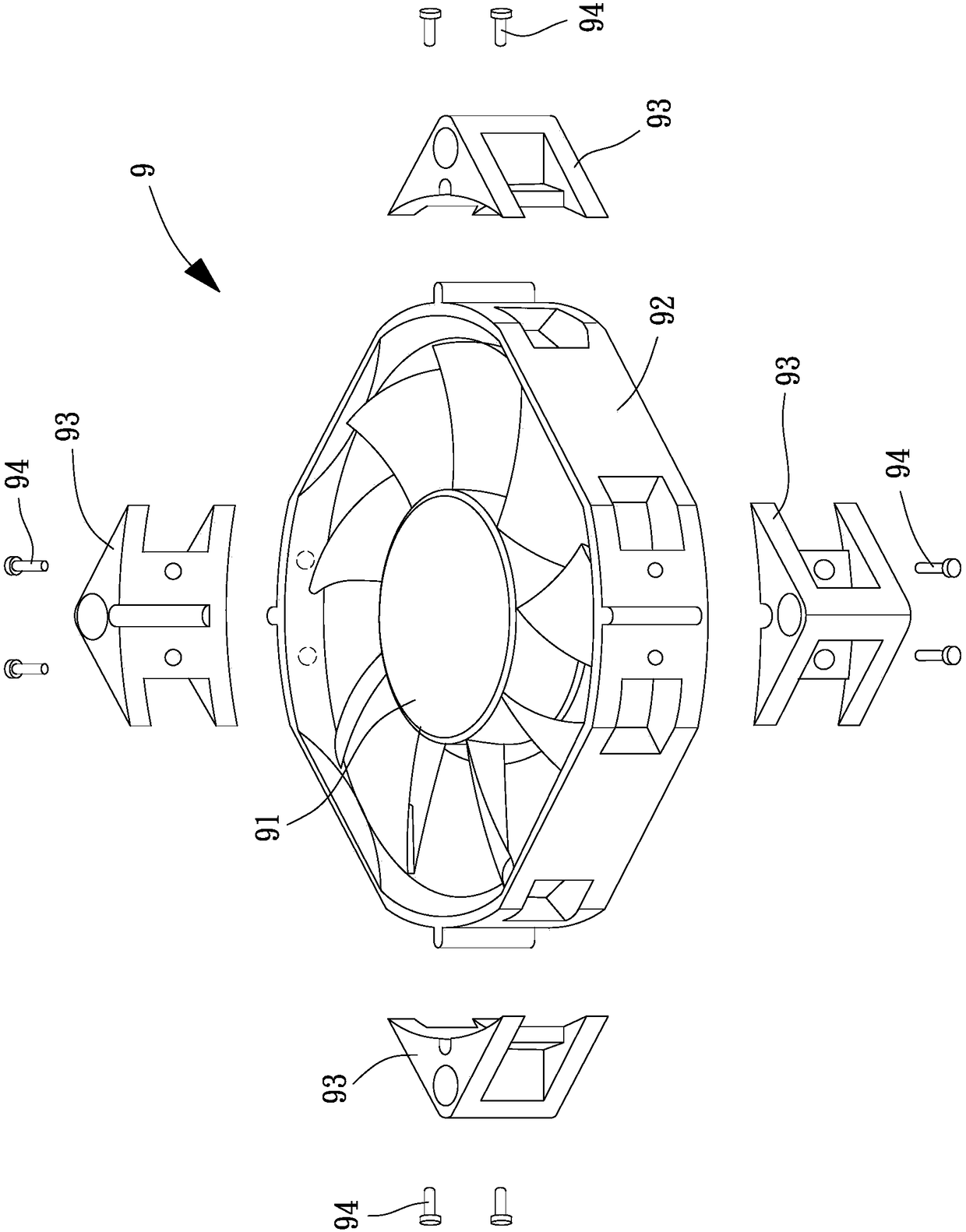

A technology of axial flow and fan, applied in axial flow pumps, components of pumping devices for elastic fluids, non-variable pumps, etc., can solve the numerous assembly steps and the overall structural complexity of axial flow fans 9 High, axial flow fan 9 assembly convenience and poor efficiency, to achieve the effect of simplifying the structure of the fan frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

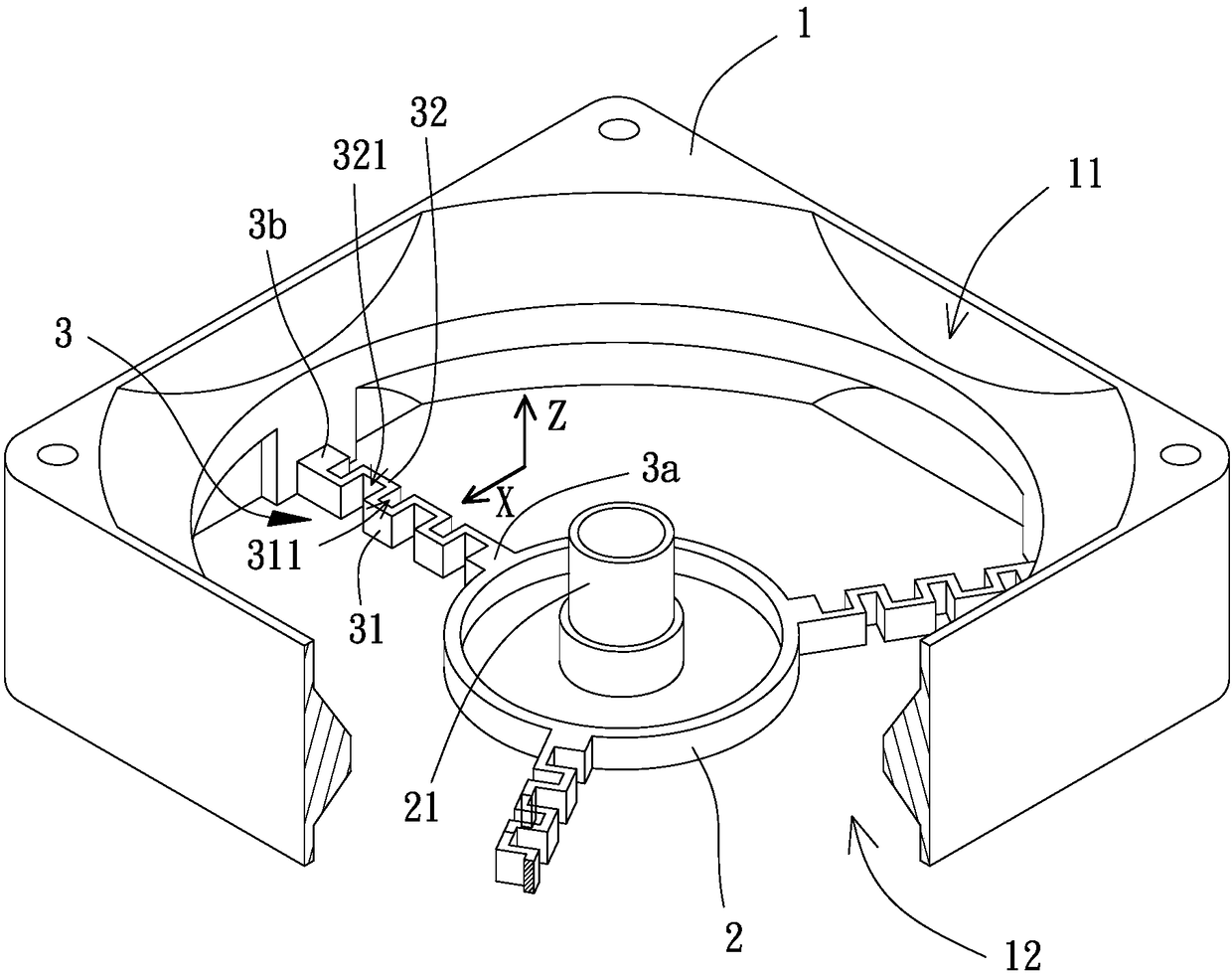

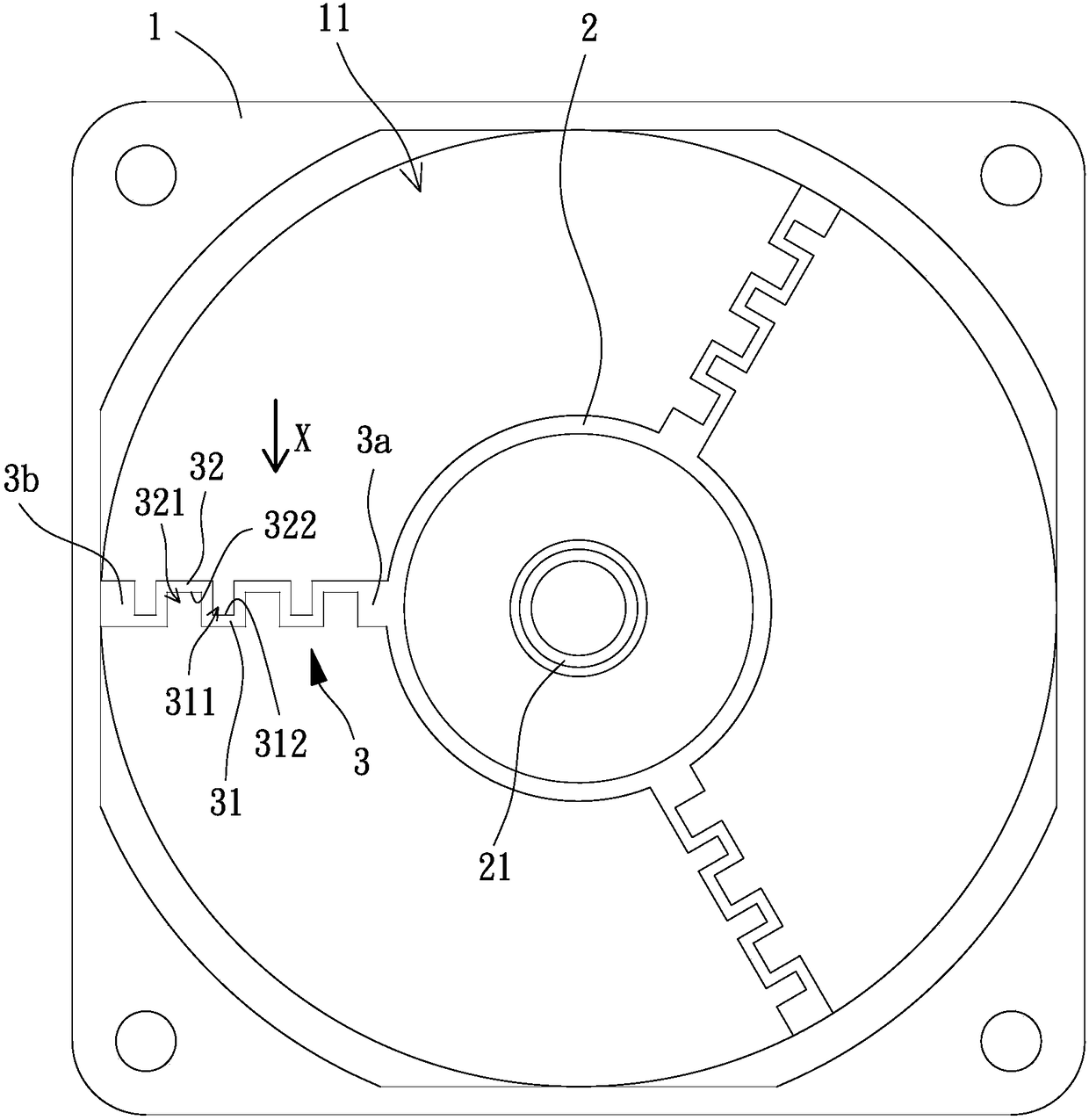

[0072] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the following is based on the preferred embodiments of the present invention and is described in detail as follows in conjunction with the accompanying drawings:

[0073] Please refer to figure 2 and 3 As shown, the fan frame of the axial flow fan according to the first embodiment of the present invention includes a casing 1, a base 2 and a plurality of connecting pieces 3, and each connecting piece 3 connects the casing 1 and the base 2 respectively. . The casing 1 is respectively provided with a vent 11 and 12 on both sides of an axial direction Z, and the two vents 11 and 12 can be used as an air inlet and an air outlet of an axial flow fan.

[0074] The base 2 has a shaft connection portion 21 extending along the axial direction Z, and the shaft connection portion 21 can be provided for the shaft of the axial flow fan. In detail, a bearin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap