Device for laying a conductive wire for welding

A technology of conductive wires and wires, which is applied in the field of devices for laying conductive wires for welding, and can solve the problems that the small radius or curvature of the welding wire cannot be well applied, and the management and welding cannot be well applied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the description section below, it is considered that the top corresponds to figure 1 The top and bottom correspond to figure 1 bottom of.

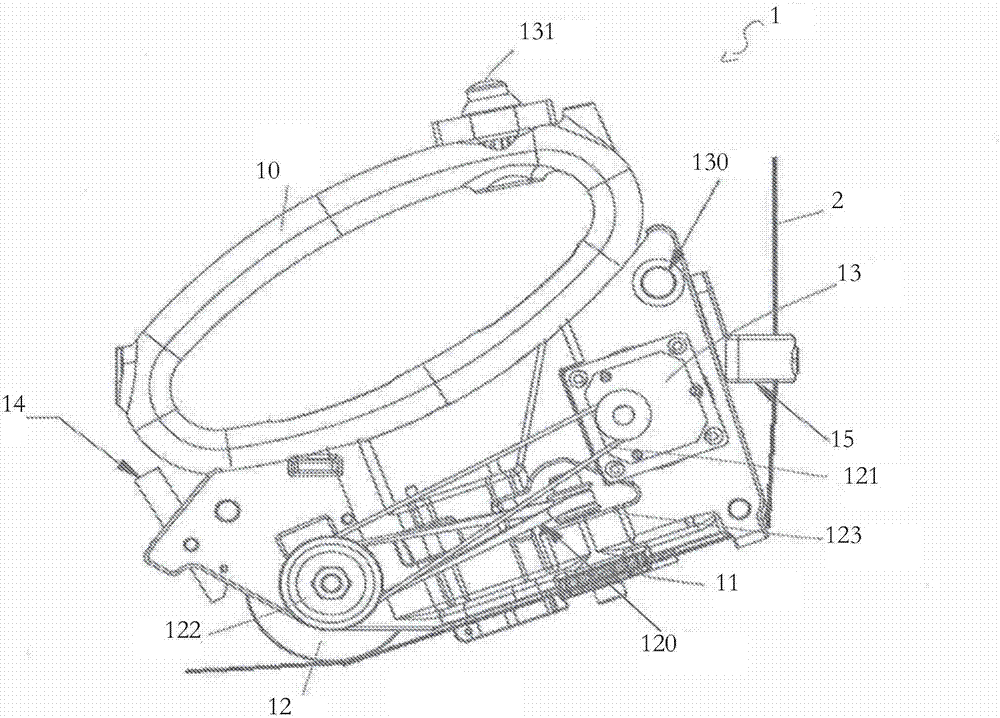

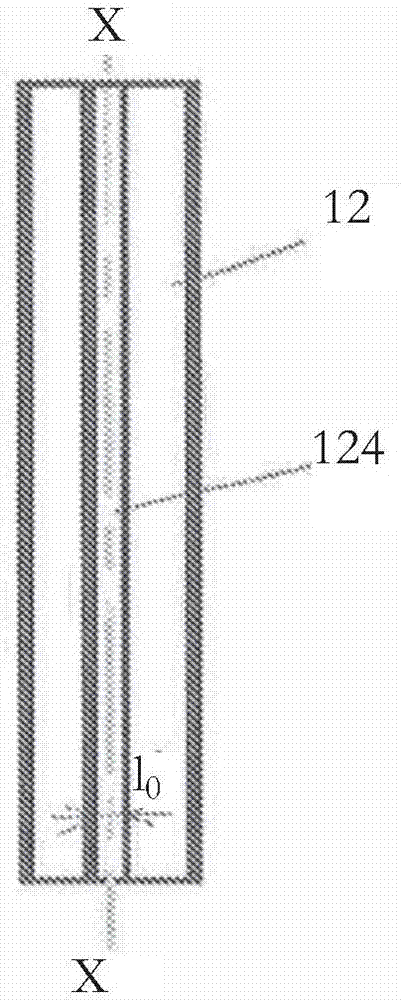

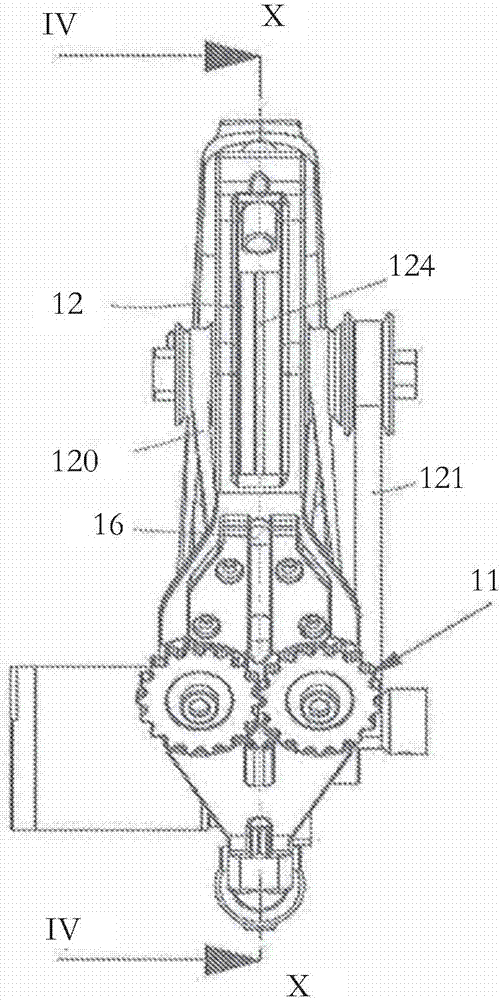

[0024] Such as figure 1 The device according to the invention, visible in FIG. 2 , comprises a spray gun 1 and a wire 2 provided by a wheel (not depicted) and arriving via a support 15 . The spray gun 1 has a handle 10 by means of which an operator can operate the spray gun 1 . The device also comprises two toothed wheels 11 and a laying wheel 12 . The laying wheel 12 is driven by a belt 121 connected to an electric drive motor 13 and the toothed wheel 11 is driven by a belt 120 connected to the laying wheel 12 . Thus, the toothed wheel 11 and the laying wheel 12 are driven together in a coordinated manner. The belts 120, 121 are connected to the wheels by toothed pulleys 122, 123 in a known manner. The drive belt 121 between the motor shaft 13 and the shaft of the laying wheel 12 is a toothed belt. There are two toothed d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com