Rapid measurement method for 3D curved surface glass

A technology of curved glass and measurement method, which is applied to measurement devices, instruments, optical devices, etc., can solve the problems of not meeting the full inspection requirements of mass production of curved glass, low measurement efficiency, etc., and achieve rapid profile measurement and measurement efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

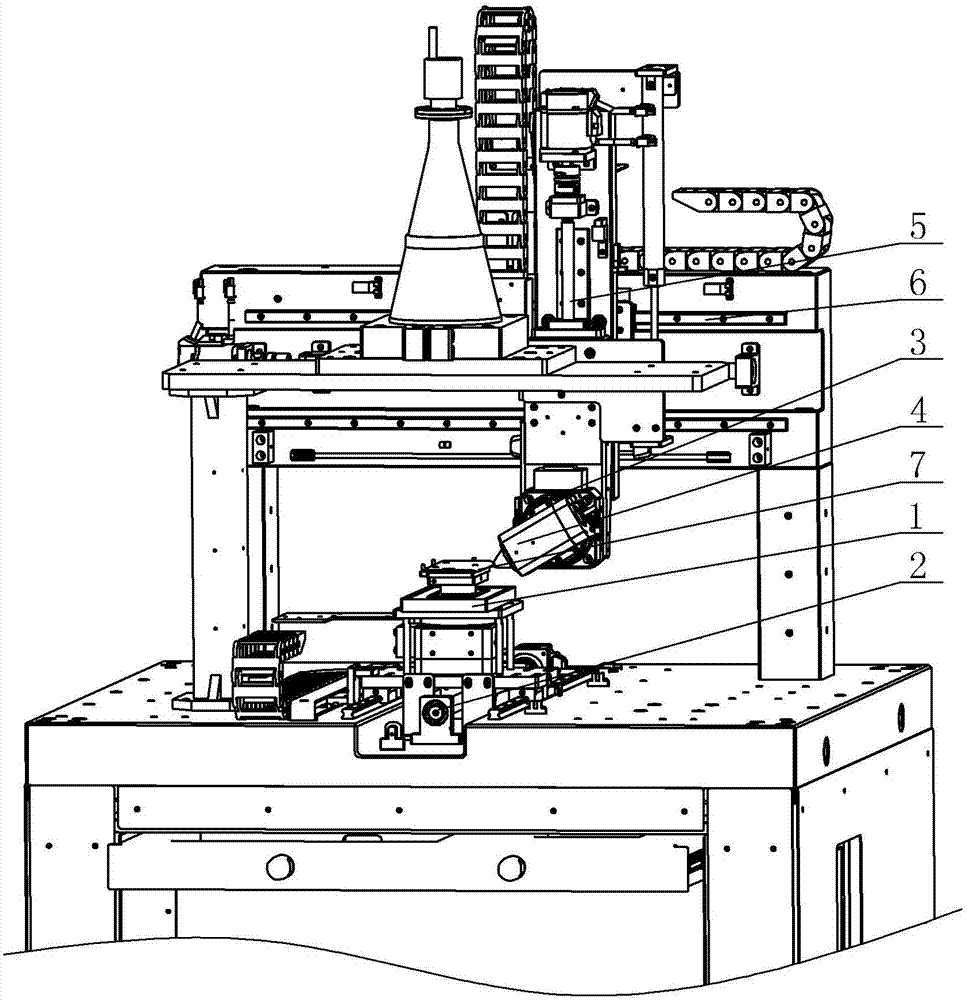

[0019] A rapid measurement method for 3D curved glass, using an image system to identify the posture and position of a 3D curved glass test piece, and using a non-contact displacement sensor to scan and measure the surface of the test piece.

[0020] The specific method is as follows: import the 3D curved glass design model into the measurement software in advance, and then design a reasonable measurement path according to the model, and then place the glass to be measured on the corresponding fixture for positioning, and obtain the target surface through the image positioning system above the fixture. Measure the position and attitude of the glass in the XY direction for positioning in the XY direction. The non-contact displacement sensor is installed on a rotary table that can rotate relative to the B axis, where the B axis is arranged parallel to the X or Y axis. The rotary axis scans the entire surface of the measured object through the non-contact displacement sensor accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com