N nail buckling device

A technology of nailing buttons and working boards, which is applied in the field of mechanical equipment, can solve the problems of slow manual packaging and achieve the effect of automatic fastening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

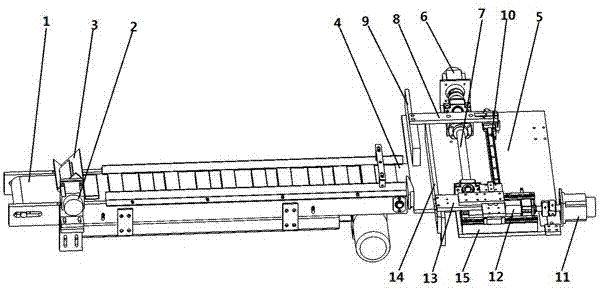

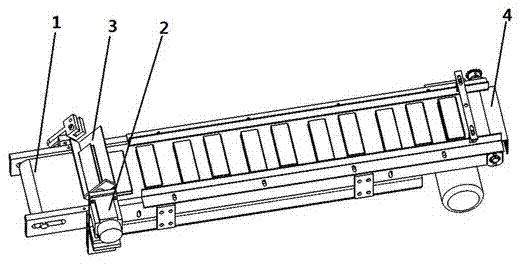

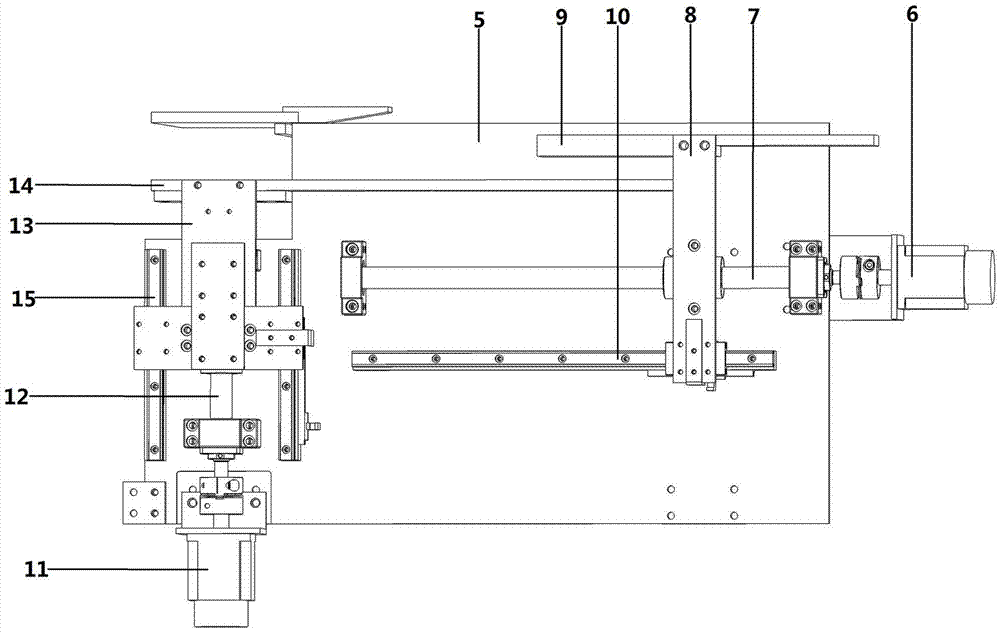

[0015] An N nail fastening device, comprising a conveyor belt 1, a turning mechanism installed at the front end of the conveyor belt, a connecting plate 4 installed at the tail of the conveyor belt 1, a working plate 5 connected to the connecting plate 4, and a control mechanism installed on the working plate 5 One, connect the pushing plate 9 of the first control mechanism, the second control mechanism installed on the working plate 5, and connect the baffle plate 14 of the second control mechanism.

[0016] There is a height difference between the working board 5 and the connecting board 4, and the working board 5 is 3-8 cm lower than the connecting board 4.

[0017] The turning mechanism includes a turning plate 3 and a motor one 2, and the turning plate 3 is connected with the motor one 2 through transmission.

[0018] Described control mechanism one comprises motor two 6, screw mandrel one 7, connection block one 8, slide rail one 10, and described slide rail one 10 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com