Coulter arrangement mode for achieving rotary cultivator cutter shaft falling

An arrangement and technology of rotary tillers, applied in the fields of tillage equipment, plows, agricultural machinery and equipment, etc., can solve the problems of increased power consumption and the inability to effectively improve the tillage depth of rotary tillers, so as to reduce power consumption and reduce ineffective radius. , Improve the effect of rotary tillage depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

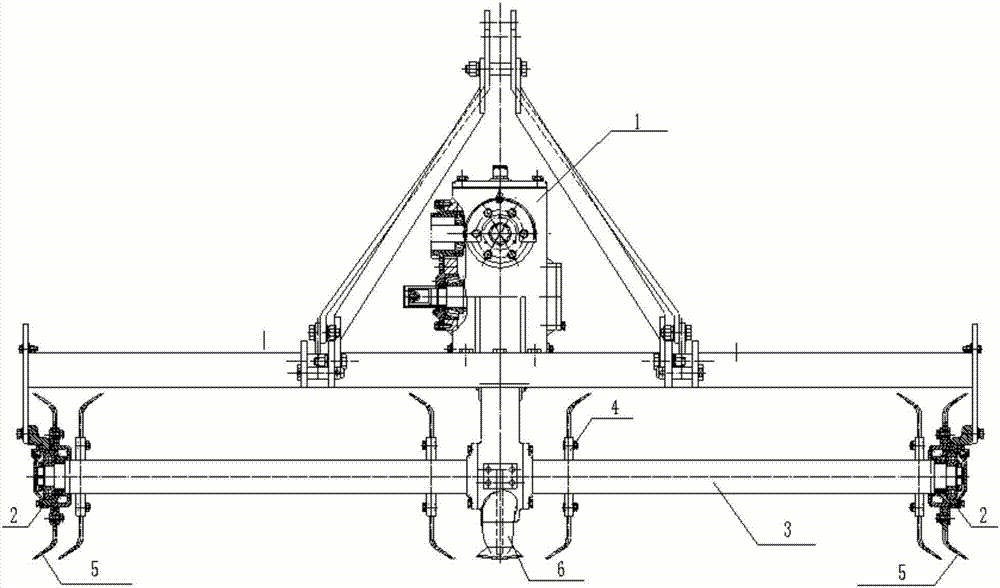

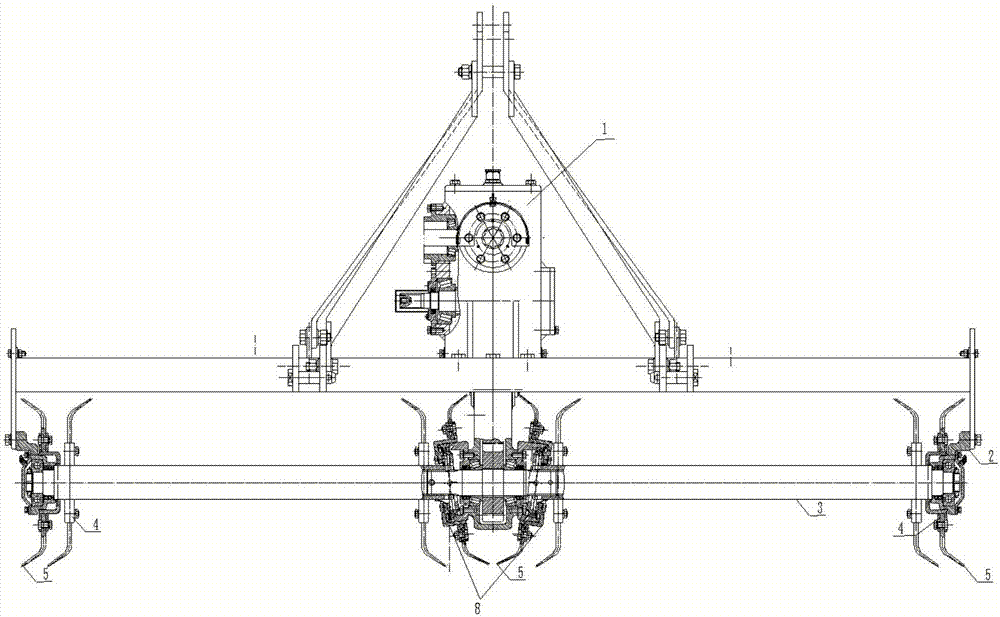

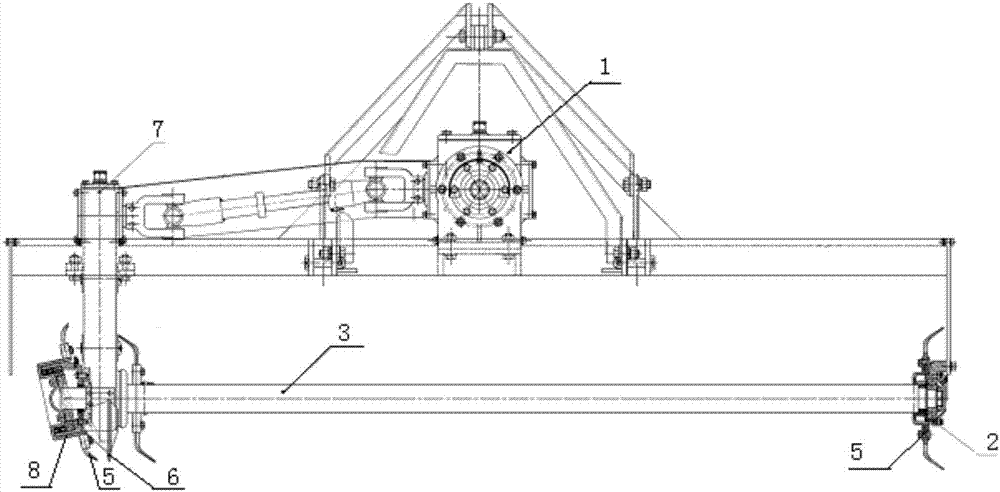

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0023] The coulter arrangement for realizing the sinking of the rotary cultivator cutter shaft 3 according to the present invention mainly includes: at least two sinking special knives 5 are arranged on the cutter seat adjacent to the cutter shaft connecting seat 2 or the coupling device 9 , the blade of the sinking special knife 5 faces the connection seat 2 or the shaft coupling device 9 and extends to the bottom of the connection seat 2 or the shaft coupling device 9 . Use the sinking special knife 5 to dig out the soil below the connecting seat 2 or the shaft coupling device 9, and realize the sinking of the connecting seat 2 or the shaft coupling device 9, thereby reducing the invalid rotation radius of the coulter and increasing the rotary tiller Plow deep.

[0024...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com