A reducer installation structure

A technology of installation structure and reducer, which is applied in the direction of printing device, printing, etc., can solve the problems of broken reducer, high rigidity of roller shaft, etc., and achieve the effect of reducing the requirement of the same cylinder, improving efficiency and preventing connection failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

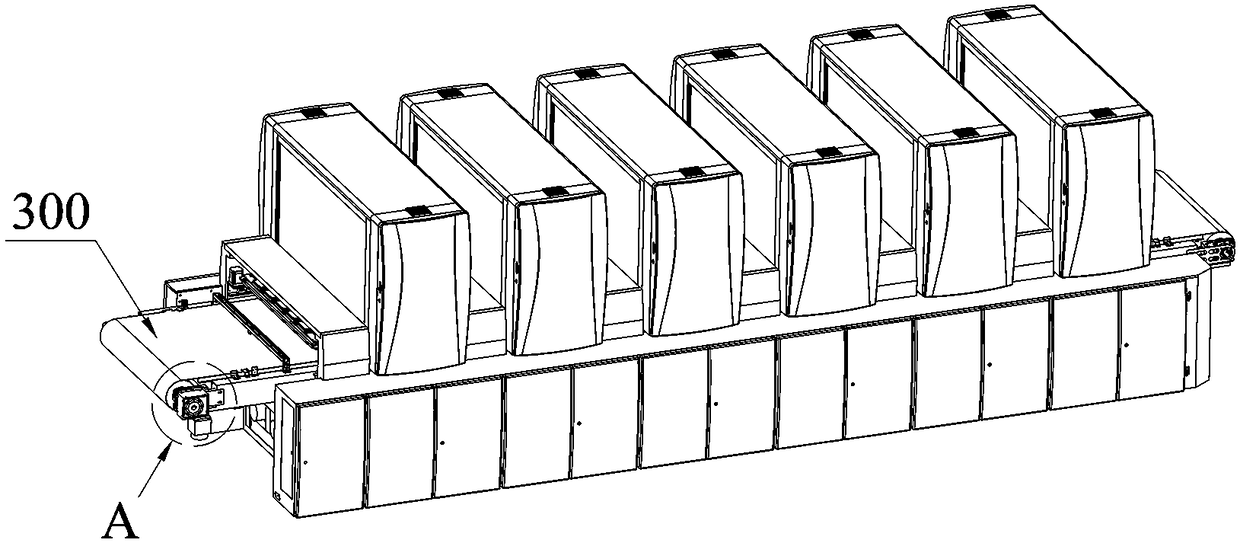

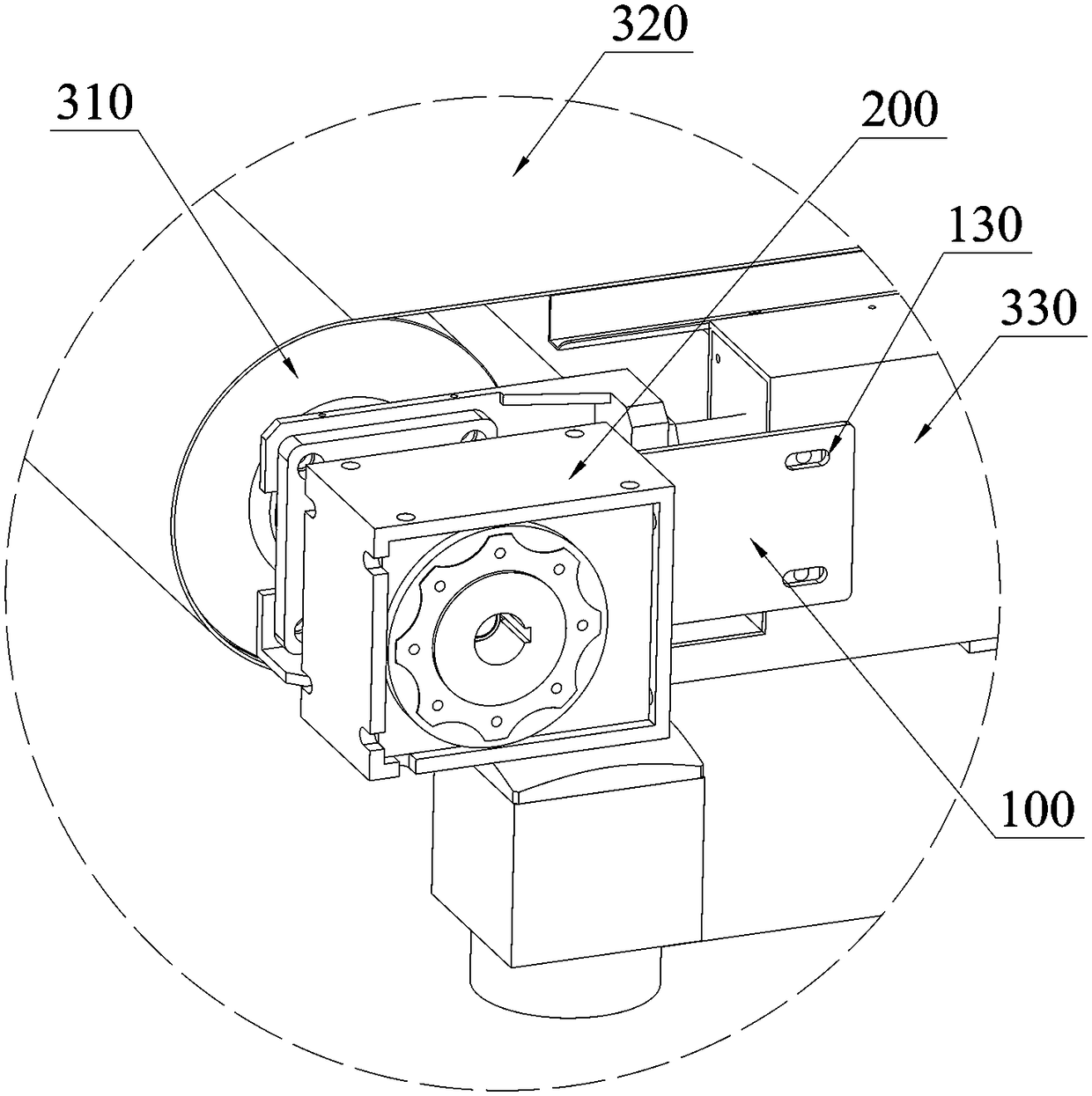

[0024] Such as Figure 1~2 As shown, a reducer 200 installation structure is used to fix the reducer 200 on the working machine, including a mounting plate 100, one end of the mounting plate 100 is connected to the reducer 200, and the other end is connected to the working machine, the reducer 200 is rotationally connected with the working machine.

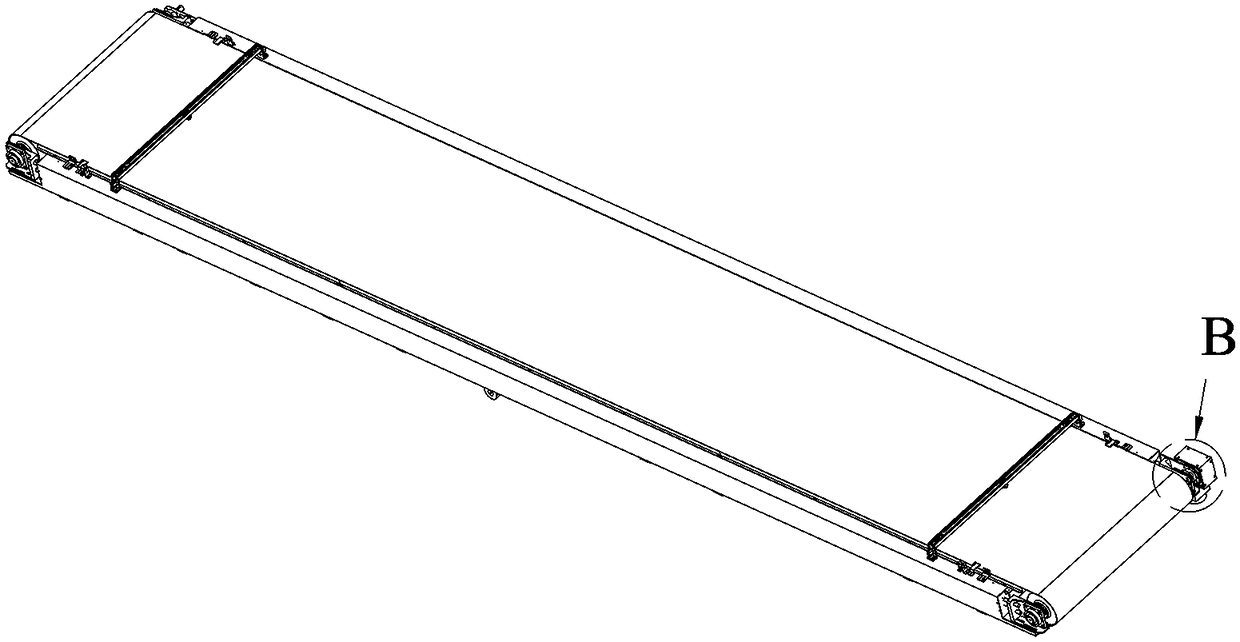

[0025] In this embodiment, the installation structure of the reducer 200 is used for the installation of the reducer 200 on the conveying platform 300 of the printer. The conveying platform 300 includes a driving roller shaft 310 and a driven roller shaft arranged in parallel, and a conveyor belt tightly sleeved on the roller shaft. 320 and the supporting part 330 for supporting the roller shaft, the reducer 200 is fixed on the supporting part 330 through the mounting plate 100 instead of being directly fixed on the supporting part 330, because the rigidity of the mounting plate 100 is much smaller than that of the supporting part...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that the thickness of the mounting plate 100 is 3mm. Others are the same as embodiment 1.

Embodiment 3

[0033] The difference between this embodiment and Embodiment 1 is that the thickness of the mounting plate 100 is 10 mm. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com