Primary color film

A primary color film and masterbatch technology, applied in the field of optical film, can solve problems such as human injury and color spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

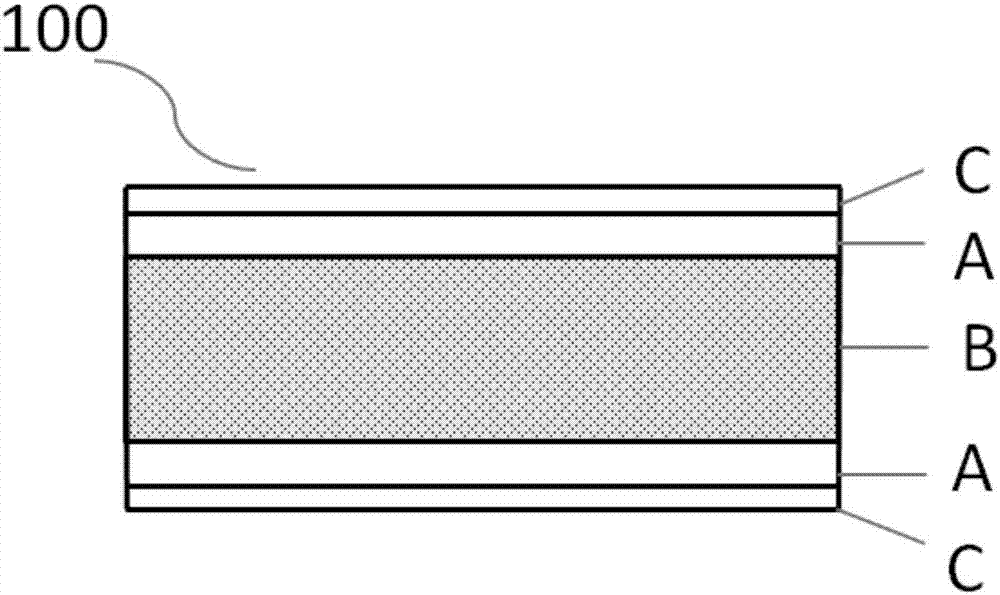

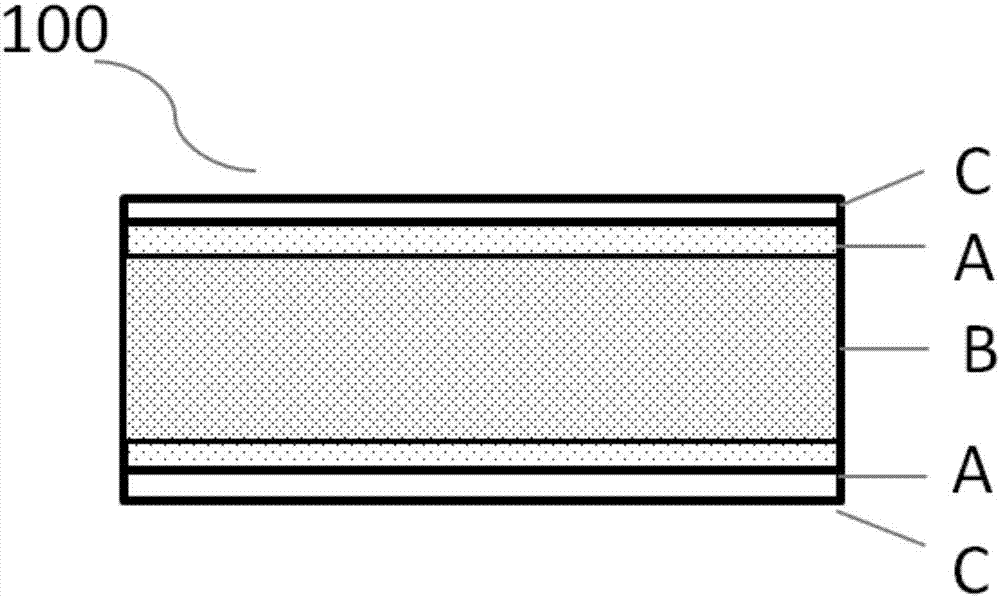

[0017] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0018] Preparation method of UV absorption masterbatch: After the UV absorption assistant and resin are proportioned according to a certain formula ratio, they are placed in a high-speed mixer for high-speed or low-speed mixing. After the mixing is completed, the mixture is taken out and placed in a twin-screw extrusion Extrusion and granulation are carried out in the machine.

[0019] The formula is shown in the following table:

[0020]

[0021] The preparation method of the masterbatch: After the dye and resin are mixed according to a certain formula ratio, they are placed in a high-speed mixer for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap