Display screen

A display screen and cathode technology, applied in the field of display screens, can solve problems such as defects, integrated circuit board signal failure, curled display, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

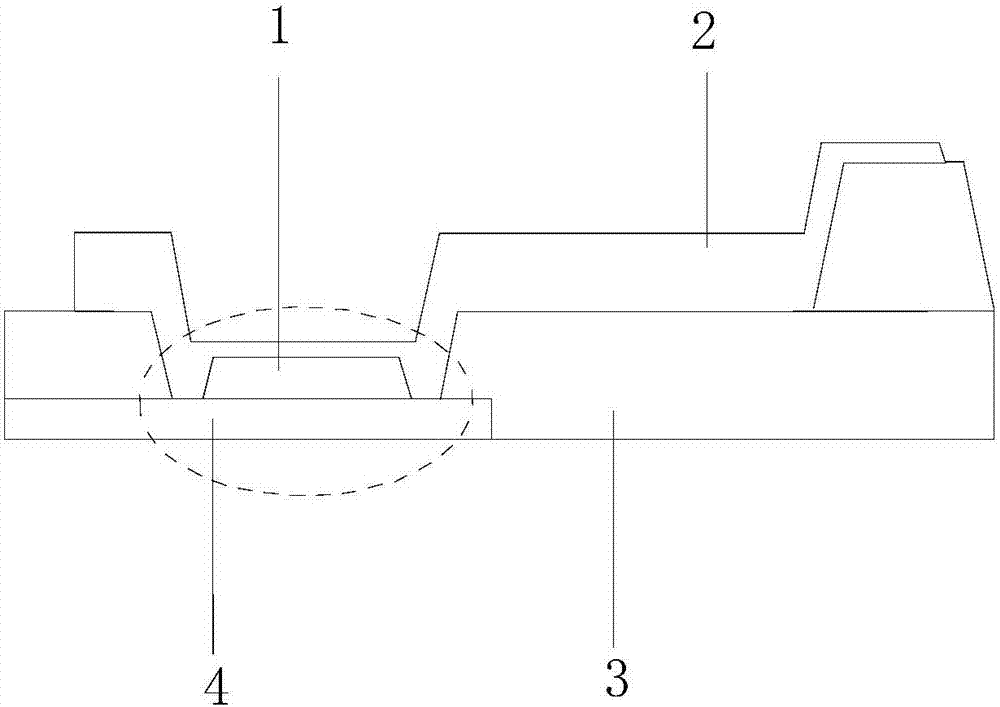

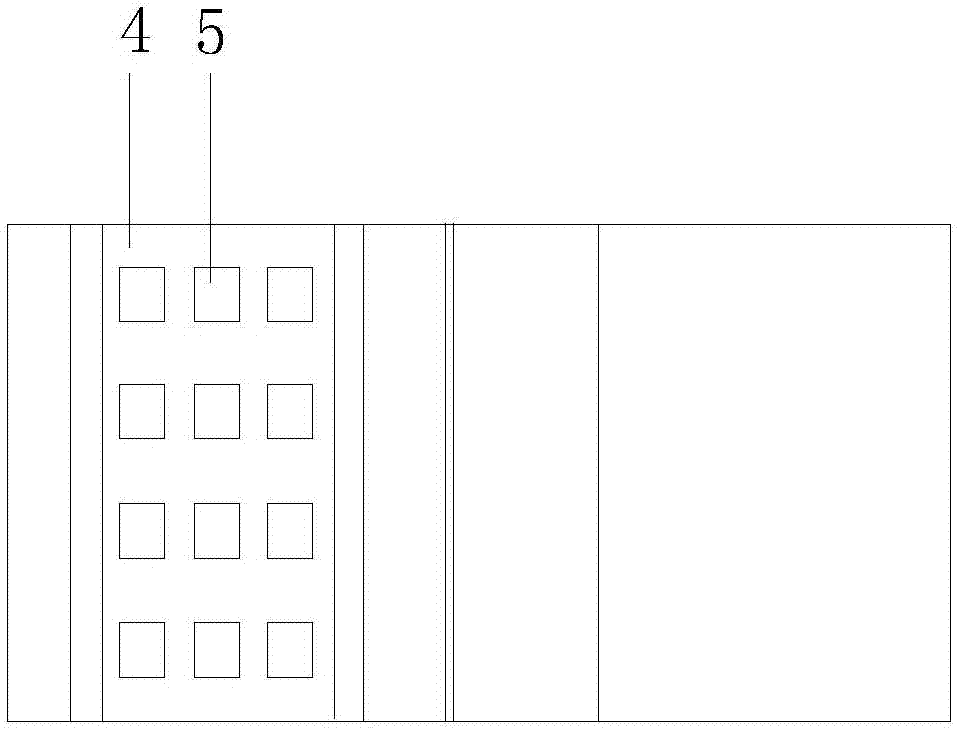

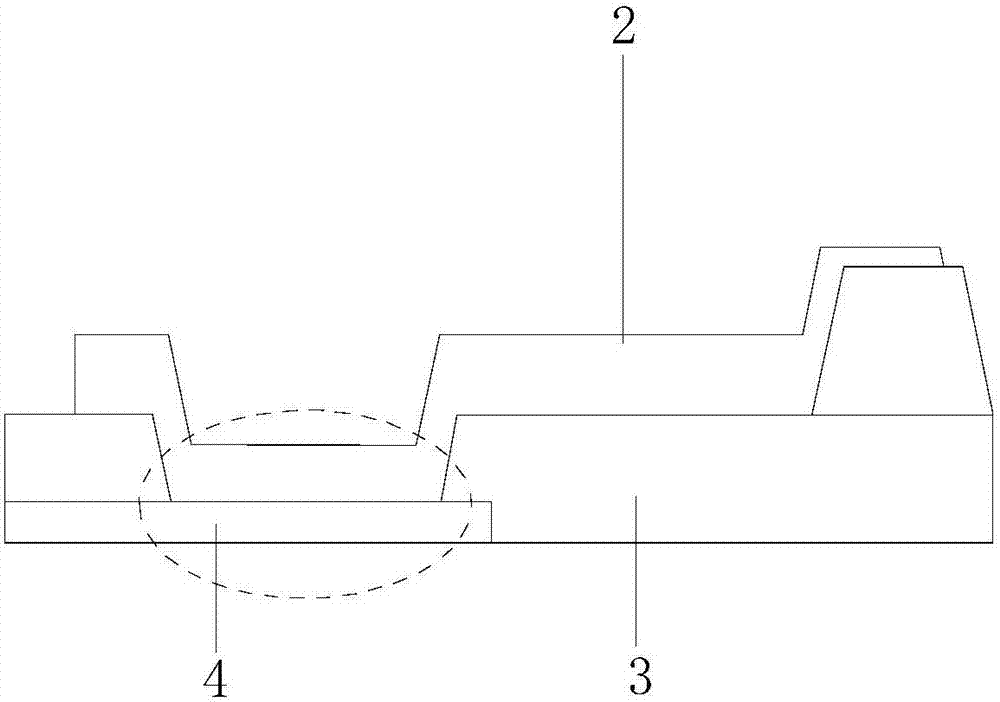

[0021] Such as Figure 1-2 As shown, the display screen includes: an integrated circuit board (IC) and an organic insulating film (PLN) 3; wherein, a power signal line 4 (Vss) is arranged on the integrated circuit board. A plurality of grooves 5 are equally arranged on the organic insulating film 3 ( figure 2 ), the cathode (cathode) 2 is disposed on the organic insulating film 3, and the cathode 2 is buried in the groove 5 and is in contact with the power signal 4 wires. Make the organic insulating film 3 near the junction of the anode 1 and the cathode 2 flat, and the cathode 2 formed under the anode 1 will not be disconnected, so that the integrated circuit board signal is transmitted to the cathode 2 in the display area, and the panel display will not be defective.

[0022] In one embodiment, image 3 As shown, an anode 1 (Anode) is arranged on the cathode 2 , and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com