Multifunctional deep water cage system

A deep-water cage and multi-functional technology, applied in application, climate change adaptation, fish farming, etc., can solve the problems of easy damage to the cage frame and anchoring foundation, and achieve simple construction, maintenance of breeding space, and typhoon resistance strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

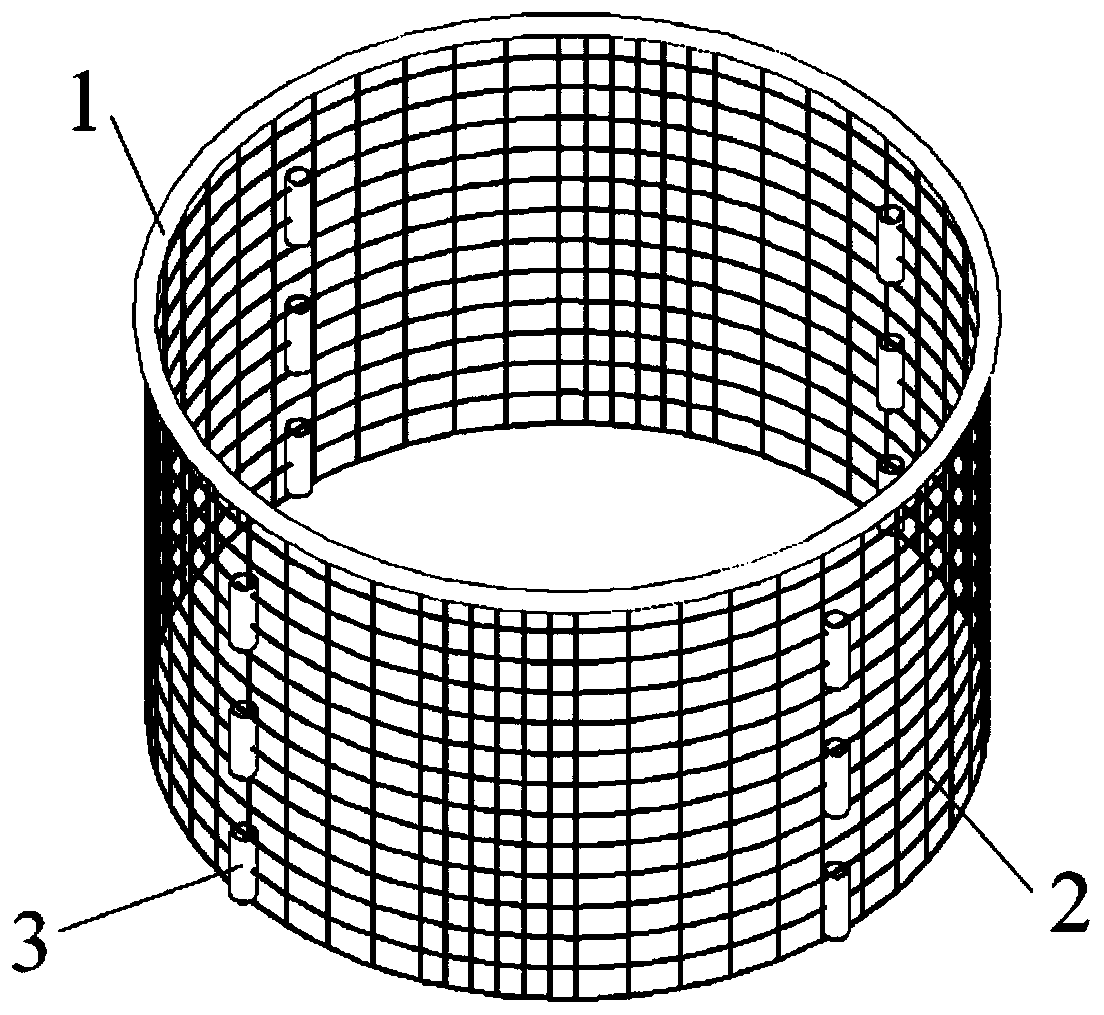

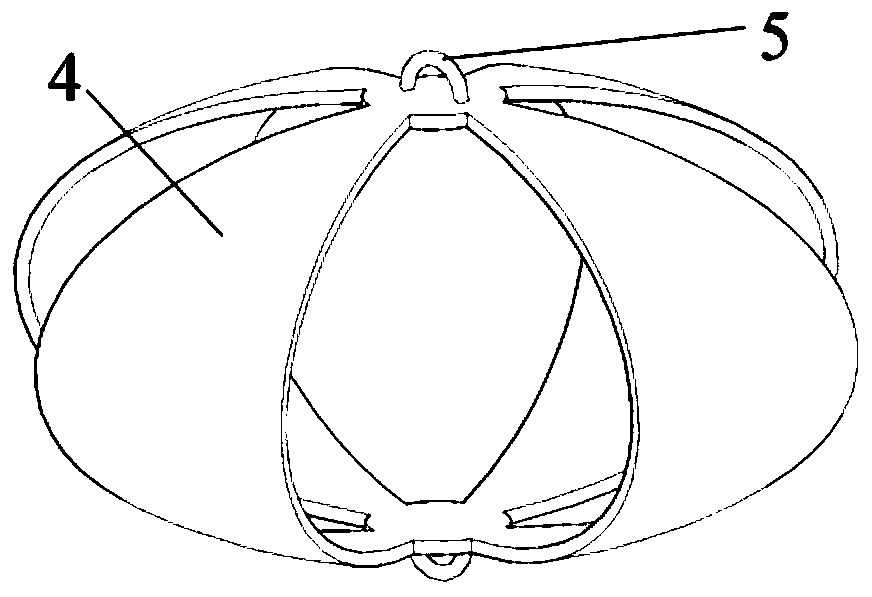

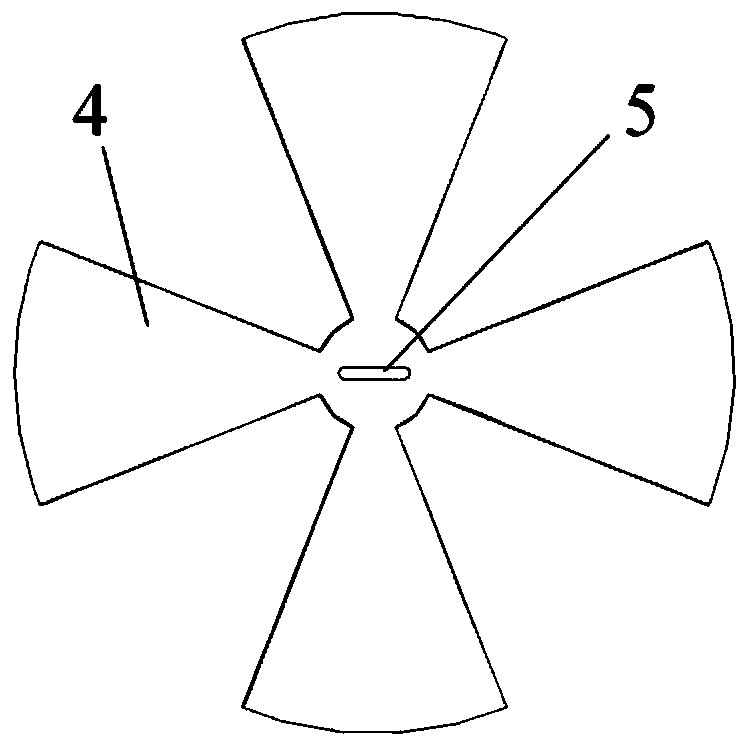

[0068] Embodiment 1: uniformly and symmetrically arrange four rows of sleeve pipes 3 coaxial with four vertical lines along the net clothing 2, such as figure 1 shown. The cage-shaped elastic section 4 is welded by four symmetrical elliptical elastic segments at both ends according to the axisymmetric distribution, and the convex surface of the symmetrical center of the two ends of the cage-shaped elastic section 4 is provided with a mooring ring 5, such as figure 2shown. Four secondary anchor chains 12 of equal length are passed through corresponding four rows of bushings 3, one end of the secondary anchor chains 12 is moored on the floating pipe frame 1, the other end is moored on the connecting ring 9, and the four secondary anchor chains 12 Bind the fixed frame 7 at the same position near the bottom of the net; one end of the main anchor chain 11 is moored on the mooring foundation 10, and the other end is moored on the connecting ring 9, and the interval "series" connec...

Embodiment 2

[0070] Embodiment 2: Five rows of sleeve pipes 3 coaxial with five vertical lines are evenly and symmetrically arranged around the netting 2, and five secondary anchor chains 12 are used to connect accordingly. The rest of the structures are the same as in Embodiment 1.

Embodiment 3

[0071] Embodiment 3: On the basis of Embodiment 1, three cage-shaped elastic joints 4 are connected in "serial" at intervals on the secondary anchor chain 12, and each cage-shaped elastic joint 4 is spaced apart with a fixing frame 7, as Figure 10 shown. The diameter of that fixed mount 7 closest to net clothing 2 is identical with the diameter of net clothing 2, and the diameter of follow-up fixed mount 7 decreases successively. Under the restraint and fixing effect of the fixing frame 7, each secondary anchor chain 12 and the cage-shaped elastic joint 4 will not collide with each other and be entangled, thereby maintaining the effectiveness of the whole.

[0072] According to the above idea, if the numbers of the cage-shaped elastic joint 4, the secondary anchor chain 12 and the fixing frame 7 are combined differently, more embodiments can be derived, which are not exhaustive here.

[0073] First of all, the present invention adopts a single-point mooring system, but it wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com