Single point mooring cage system with net fixing function

A technology of fixed function and net clothing, which is applied in the field of single-point mooring cage system, can solve the problems of low work efficiency, increase of breeding cost, increase of labor time, etc., and achieve the effect of simple construction, small cumulative weight and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

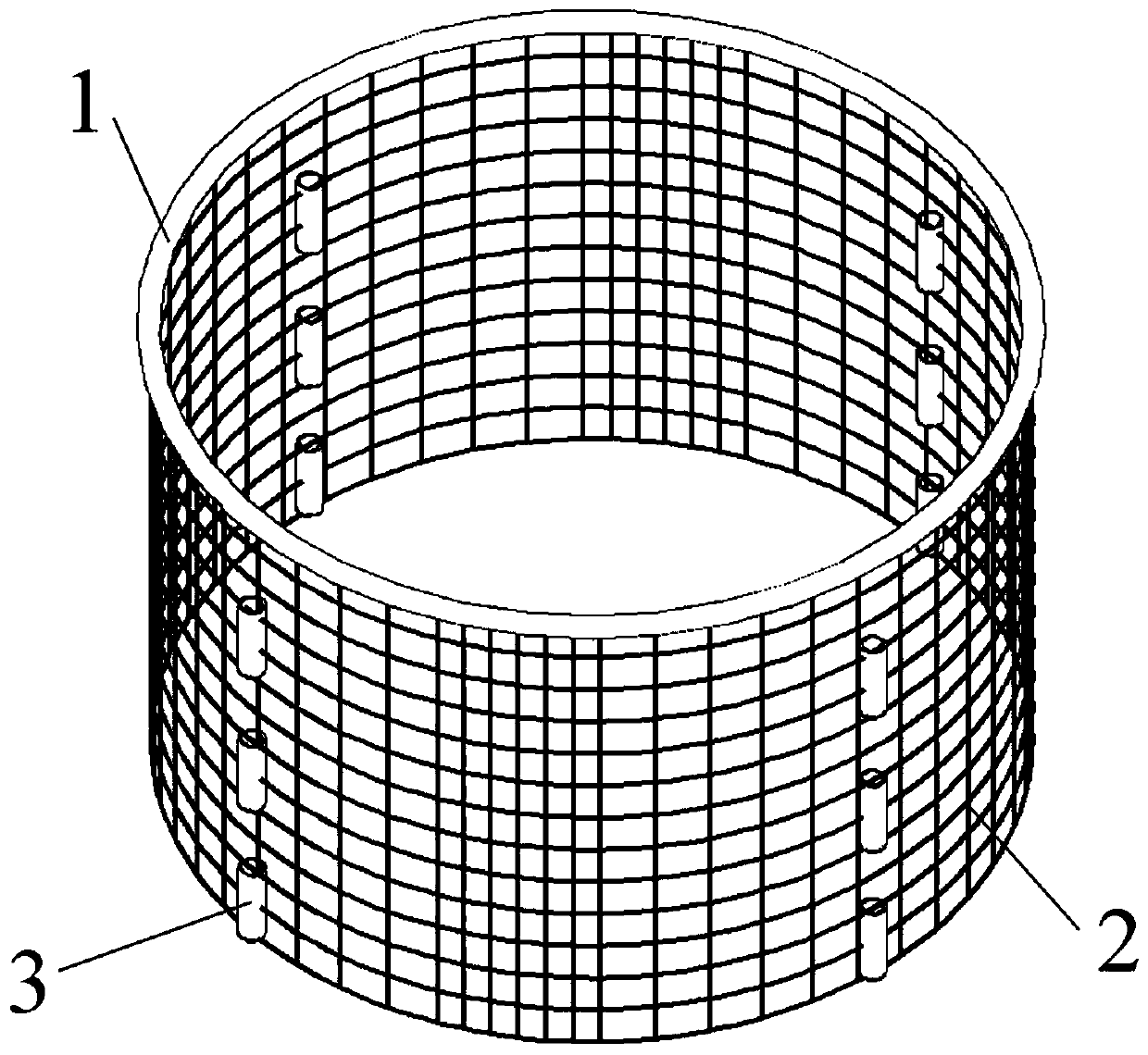

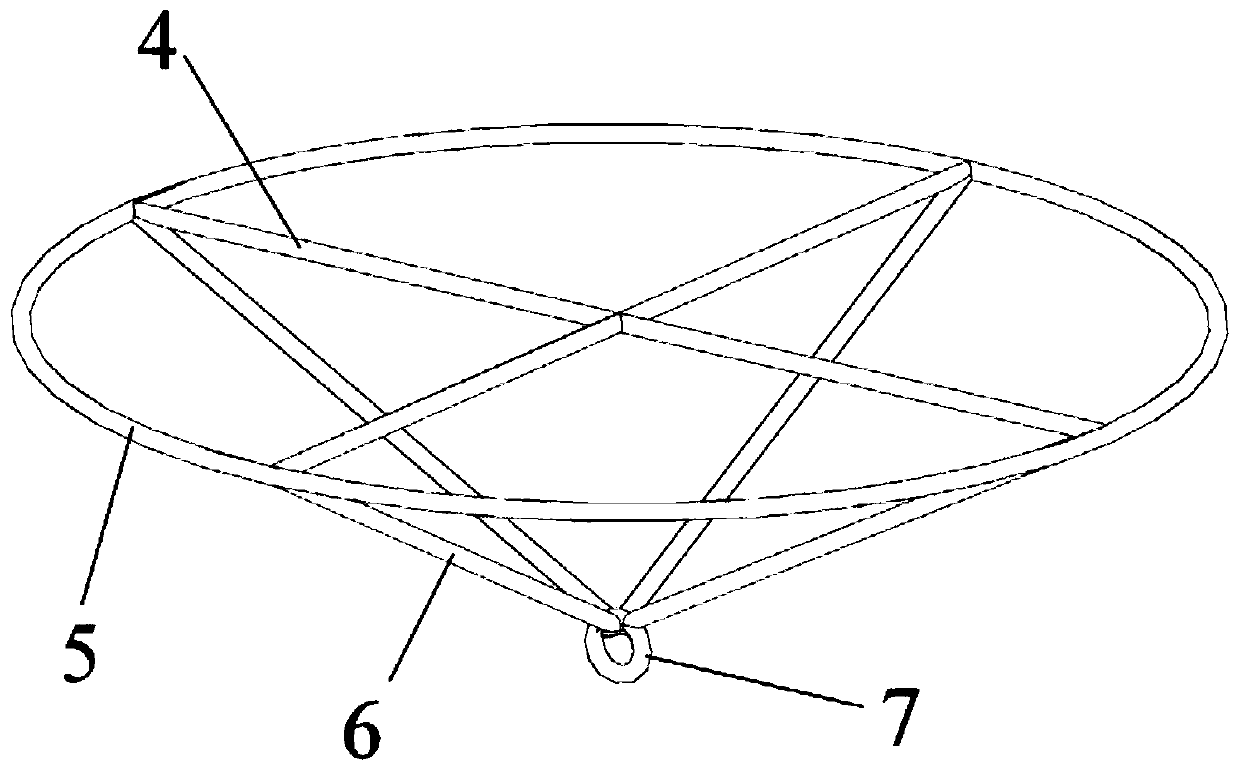

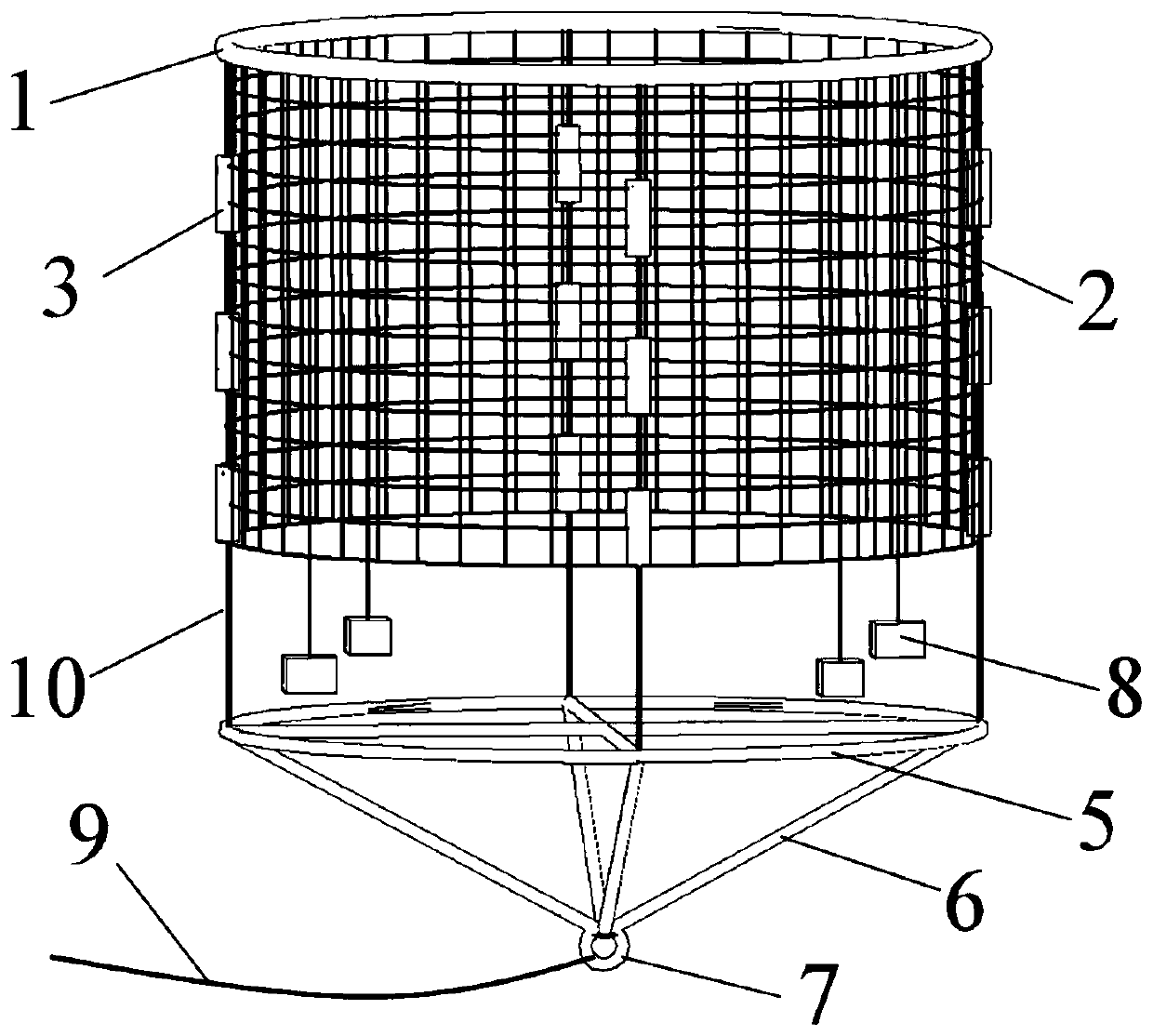

[0053] Embodiment 1: uniformly and symmetrically arrange four rows of sleeve pipes 3 coaxial with the plumb line around the net clothing 2, such as figure 1 shown. Pass four secondary anchor chains 10 through the corresponding four rows of casing pipes 3 , one end of the secondary anchor chains 10 is moored on the floating pipe frame 1 , and the other end is moored on the ring pipe 5 of the force component frame 4 . One end of the primary anchor chain 9 is moored on the mooring foundation 11 , and the other end is moored on the mooring ring 7 of the component frame 4 . The length of secondary anchor chain 10 should be greater than the depth of cage. In this way, a single-point mooring cage system with net fixing function is formed, such as Figure 4 shown.

[0054] In this embodiment, the resultant force of the four secondary anchor chains 10 is equal to the pulling force of the primary anchor chain 9, so the material strength and cross-sectional area of the secondary anc...

Embodiment 2

[0055] Embodiment 2: Five rows of sleeve pipes 3 coaxial with the plumb line are evenly and symmetrically arranged around the netting 2, and five secondary anchor chains 10 are used to connect accordingly. The connection method is the same as in Embodiment 1.

Embodiment 3

[0056] Embodiment 3: Six rows of sleeve pipes 3 coaxial with the plumb line are evenly and symmetrically arranged around the netting 2, and six secondary anchor chains 10 are used to connect accordingly. The connection method is the same as in Embodiment 1.

[0057] According to the above ideas, more embodiments can be derived, which are not exhaustive here.

[0058] On the one hand, the present invention adopts a single-point mooring system, but it will not produce greater stress concentration at the mooring points and joints of the net cage frame. On the other hand, it can effectively reduce the volume loss rate of the net cage, and the net Clothes replacement, net cleaning or pulling net fish collection operations have little impact, and can better adapt to the development needs of deep-water cage culture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com