Electric generator

A generator and nacelle technology, applied in the direction of engines, wind power generation, wind turbines, etc., can solve the problems of inability to effectively control local load fluctuations, excessive use of pitch devices, large inertia, etc., to achieve strong typhoon resistance, compact layout, The effect of slowing down the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

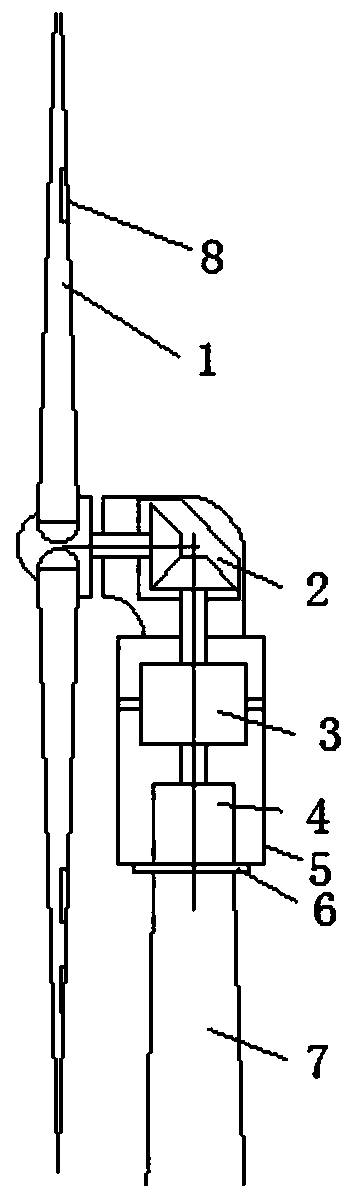

[0018] Embodiment 1: as figure 1 As shown, a wind power generator of the present invention includes an independently variable pitch wind rotor 1, a direction-changing gear box 2, an airtight vertical nacelle 5, an electric control cabinet, a generator 4, and a yaw device 6. The wind rotor 1 Connect the generator 4 in the vertical nacelle 5 through the direction-changing gearbox 2, the vertical nacelle 5 is placed on the top of the tower 7, and the yaw device 6 is installed between the vertical nacelle 5 and the tower 7 (using the existing structure) .

[0019] A speed-up gearbox is connected between the direction-changing gearbox and the generator.

[0020] The wind rotor blades are two pieces, which are evenly arranged along the circumference of the hub, and the side wings are arranged at a distance of 5-15% from the tip of each blade. The width of the side wings is 1 / 10-1 / 7 of the width of the blade, and the length is the length of the blade. 1 / 6-1 / 8 of. The reversing gea...

Embodiment 2

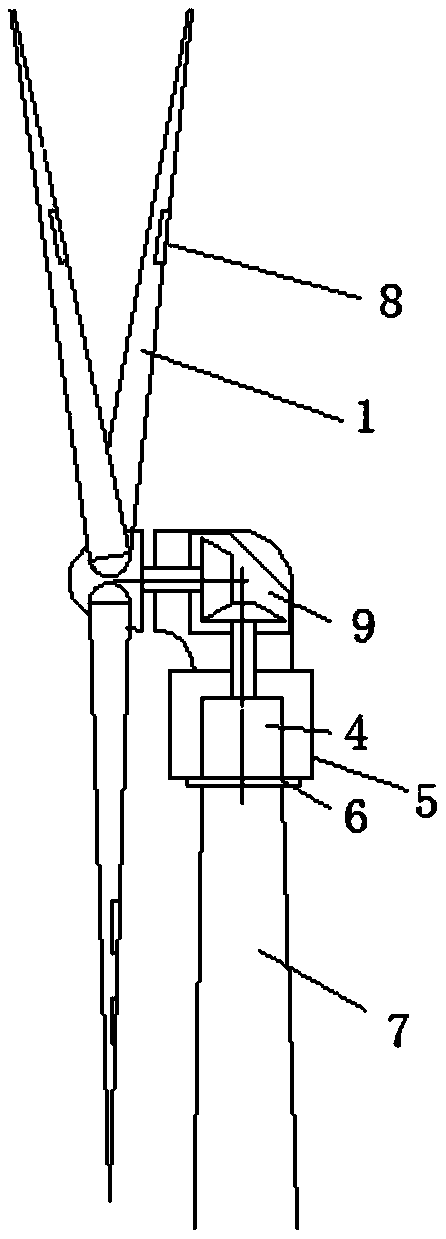

[0021] Embodiment 2: This embodiment is different from Embodiment 1 in that: the direction-changing gearbox in this example is a direction-changing speed-up gearbox; the wind rotor blades are three.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com