Full-automatic leakage testing device

A leak tester, fully automatic technology, applied in the direction of using liquid/vacuum for liquid tightness measurement, etc., can solve the problems of inaccurate test results, difficulty in ensuring product quality, corporate integrity risks, etc., and achieve accurate air tightness detection. High degree, flexible structure, the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

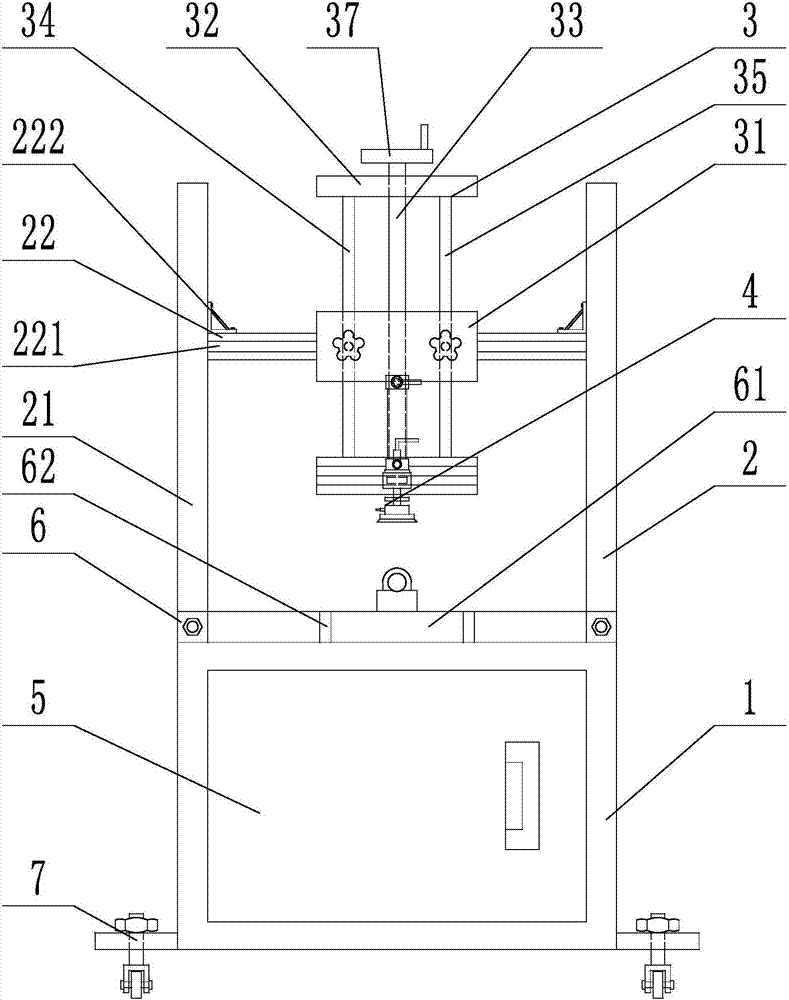

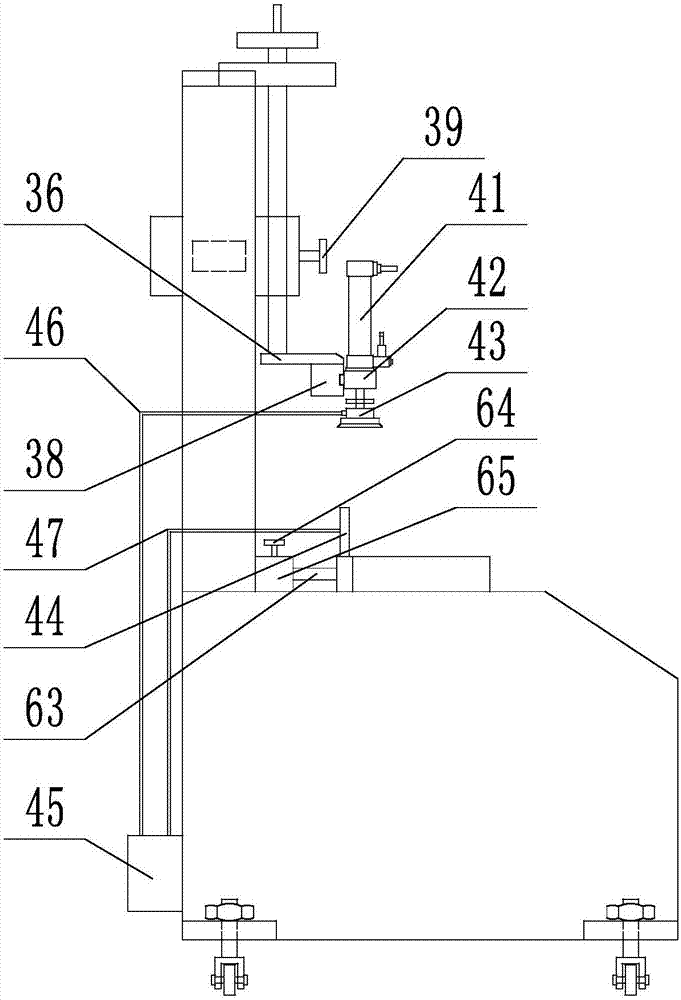

[0013] Such as figure 1 and 2 As shown, the present invention includes a main control box 1, an I-shaped support frame 2, a guide support assembly 3 and a leak detection assembly 4, a door 5 is installed on the front side of the main control box 1, and the I-shaped support frame 2 is installed At the rear position of the top surface of the main control box 1, the I-shaped support frame 2 includes two columns 21 and a beam 22, the bottom of which is equipped with an adjustable support frame 6, and the front side and the top surface of the beam 22 are Each is provided with a track 221, and a set of limit blocks 222 are installed at both ends of the track 221 located on the top surface. The guide support assembly 3 is movably installed in the two tracks 221, and a part of the leak detection assembly 4 is installed on the On the guide support assembly 3, the other part is installed on the adjustable support frame 6, and a group of universal wheels 7 are respectively installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com