Single-hole automatic positioning ground wire-free electrical plug socket assembly

An automatic positioning, plug and socket technology, applied in the direction of electrical components, circuits, two-component connection devices, etc., can solve the problems of prone to electric shock accidents, inconvenient use, etc., achieve good economic and safety benefits, and prevent electric shock accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

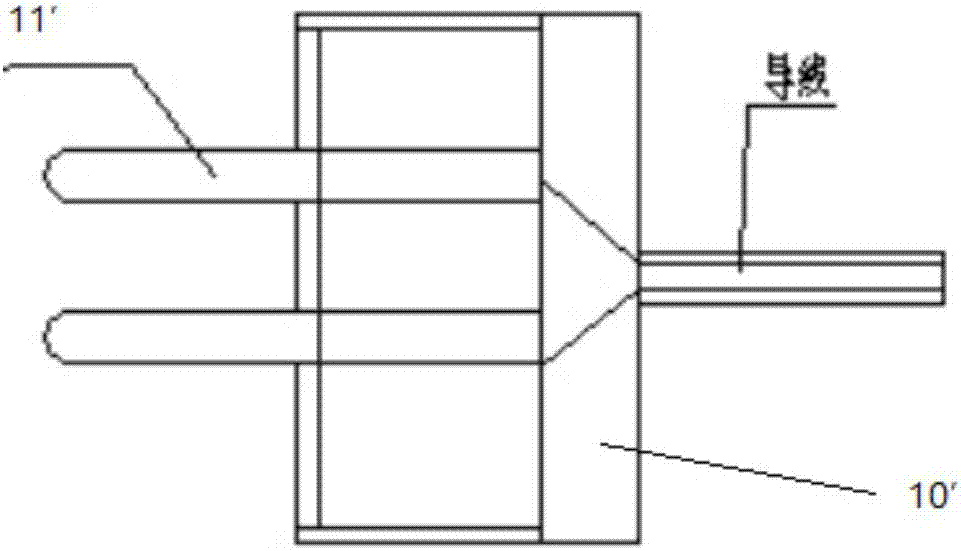

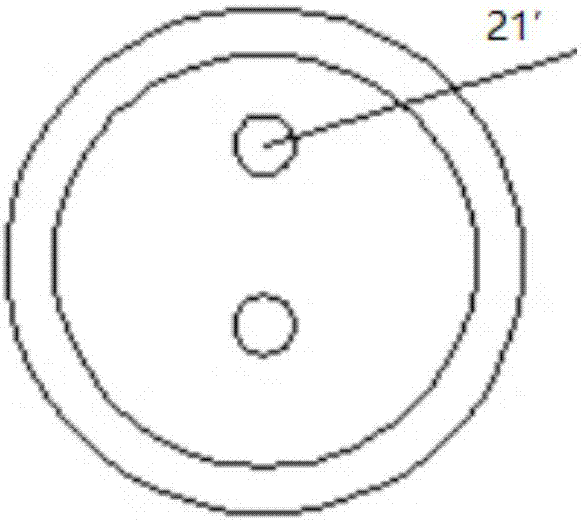

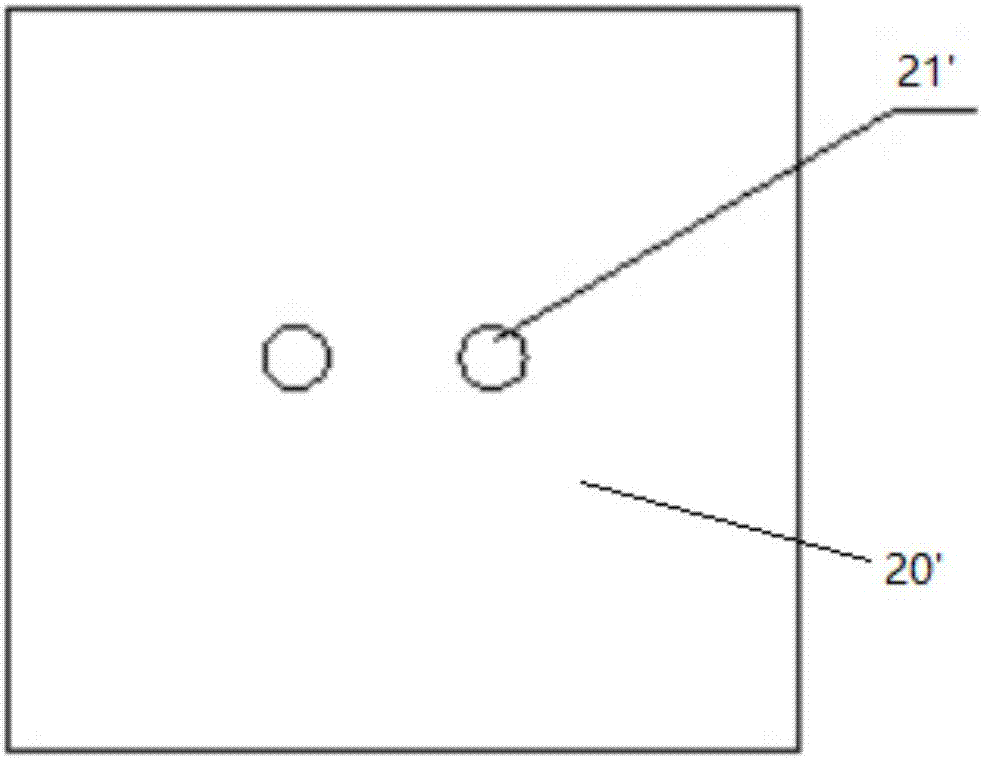

[0024] Such as Figure 4-7 As shown, a single-hole automatic positioning non-earth type electrical plug and socket assembly includes: a plug 10 and a socket 20, the plug 10 includes a live wire pole 11, surrounds the live wire pole 11 and is spaced from the live wire pole 11 by a distance The zero line pole ring 12 of the distance, the socket 20 includes a jack 21 matched with a live line pole column 11, and an annular slot 22 matched with the neutral line pole ring 12, and the outer circumference of the neutral line pole ring 12 surrounds a retractable insulating protection Cover 13.

[0025] Specifically, the end of the retractable insulating protective cover 13 close to the socket elastically expands and contracts, and the end of the retractable insulating protective cover 13 away from the socket 20 abuts against the insulating shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com