Guides for nuclear fuel pellet loading

A guiding device and nuclear fuel technology, applied in nuclear engineering, nuclear power generation, greenhouse gas reduction, etc., can solve problems such as difficult installation, low efficiency, and easy scratches on the outer surface of nuclear fuel pellets, so as to improve the degree of automation and improve The effect of loading speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

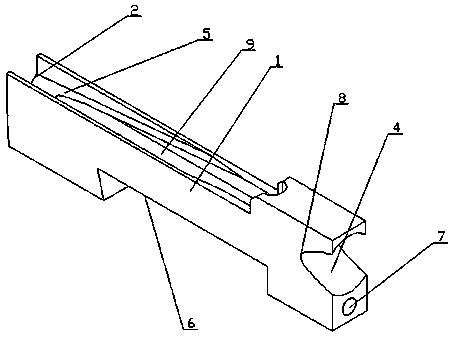

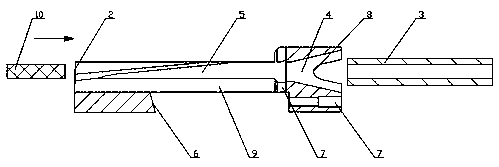

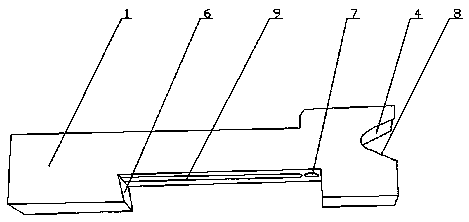

[0034] Such as figure 1 , 2 As shown in and 3, the guide device for nuclear fuel pellet filling includes a guide block 1, the front end side wall of the guide block 1 is provided with a material inlet 2, and the rear end side wall of the guide block 1 is provided with a The cladding tube 3 communicates with the trumpet-shaped discharge port 4, the feed port 2 and the discharge port 4 are connected through the guide chute 5 opened, and the feed port 2, the guide chute 5 and the discharge port 4 constitute A straight-line pellet guide channel is established; along the direction from the inlet 2 to the outlet 4, the diameter of the trumpet-shaped outlet 4 gradually becomes larger, and the bottom of the guide chute 5 is also provided with a guide groove 9. The groove 9 is opened from the material inlet 2 to the material outlet 4 and opened to the material outlet 4, and the side wall of the guide groove 9 and the groove bottom of the guide chute have an arc transition. In this emb...

Embodiment 2

[0036] Such as figure 1 , 2 As shown in and 3, compared with embodiment 1, this embodiment optimizes the guide block 1, and the guide block 1 is also provided with a fixed groove 6, the fixed groove 6 is located below the guide chute 5, and the notch of the fixed groove 6 faces Next, in this embodiment, the fixing groove 6 enables the guide block 1 to be clamped on the support, thereby preventing the guide block 1 from shaking during work.

Embodiment 3

[0038] Such as figure 1 and 2 As shown, compared with Embodiment 2, the present embodiment optimizes the guide chute 5, and there is a screw positioning through hole 7 between the groove bottom of the guide chute 5 and the groove top of the fixed groove 6; the groove bottom of the guide chute 5 There is also a guide groove 9 between the groove top of the fixing groove 6. In this embodiment, through the screw positioning through hole 7, the guide block 1 can be further stably fixedly connected to the support, thereby avoiding the During operation, the shaking of the guide block 1 affects the entry of the nuclear fuel pellets into the cladding tube 3 , and the guide groove 9 can move the nuclear fuel pellets 10 more stably along the guide chute 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com