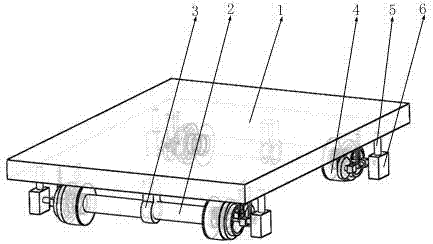

Walking platform provided with gear variable drive wheels

A walking platform and driving wheel technology, applied in the direction of toothed components, belts/chains/gears, motor vehicles, etc., can solve the problems that the driving wheel cannot drive the walking platform, the load is heavy, and the actual use is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

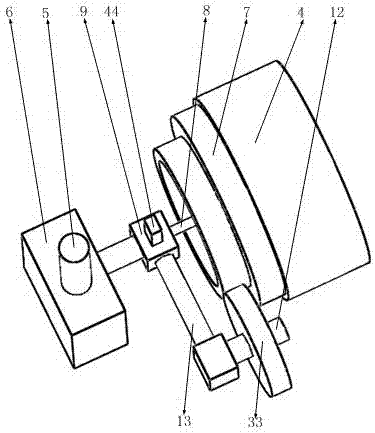

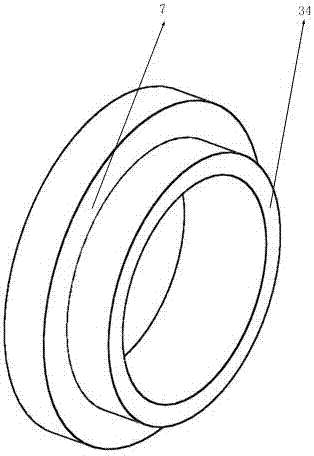

[0038] Specific embodiments: when the walking platform is working, the spring 26 is in a freely retractable state, and the pull rod 32 is not in contact with the transmission hole 28; The motor shaft drives the first transmission shaft 13 to rotate; the first transmission shaft 13 drives the support shaft 12 to rotate; the support shaft 12 drives the third transmission gear 33 to rotate; the third transmission gear 33 drives the second drive gear 34 to rotate; the second drive gear 34 Drive the transmission ring to rotate; the rotation of the transmission ring drives the wheel housing 25 to rotate; the wheel housing 25 drives the first drive gear 16, the third drive gear 42 and the fourth drive gear 43 to rotate; the first drive gear 16, the third drive gear Gear 42 and the fourth driving gear 43 drive the first driving wheel 19, the second driving wheel 40 and the third driving wheel 41 to rotate respectively; the first driving wheel 19, the second driving wheel 40 and the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com