Double-end feeding tenon planting equipment

A feeding, double-end technology, applied in the field of double-end feeding tenoning equipment, can solve the problems of unguaranteed machining accuracy, unsolved technical problems, inaccurate positioning, etc., to achieve simple and reliable control, improve practicability, and reduce manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

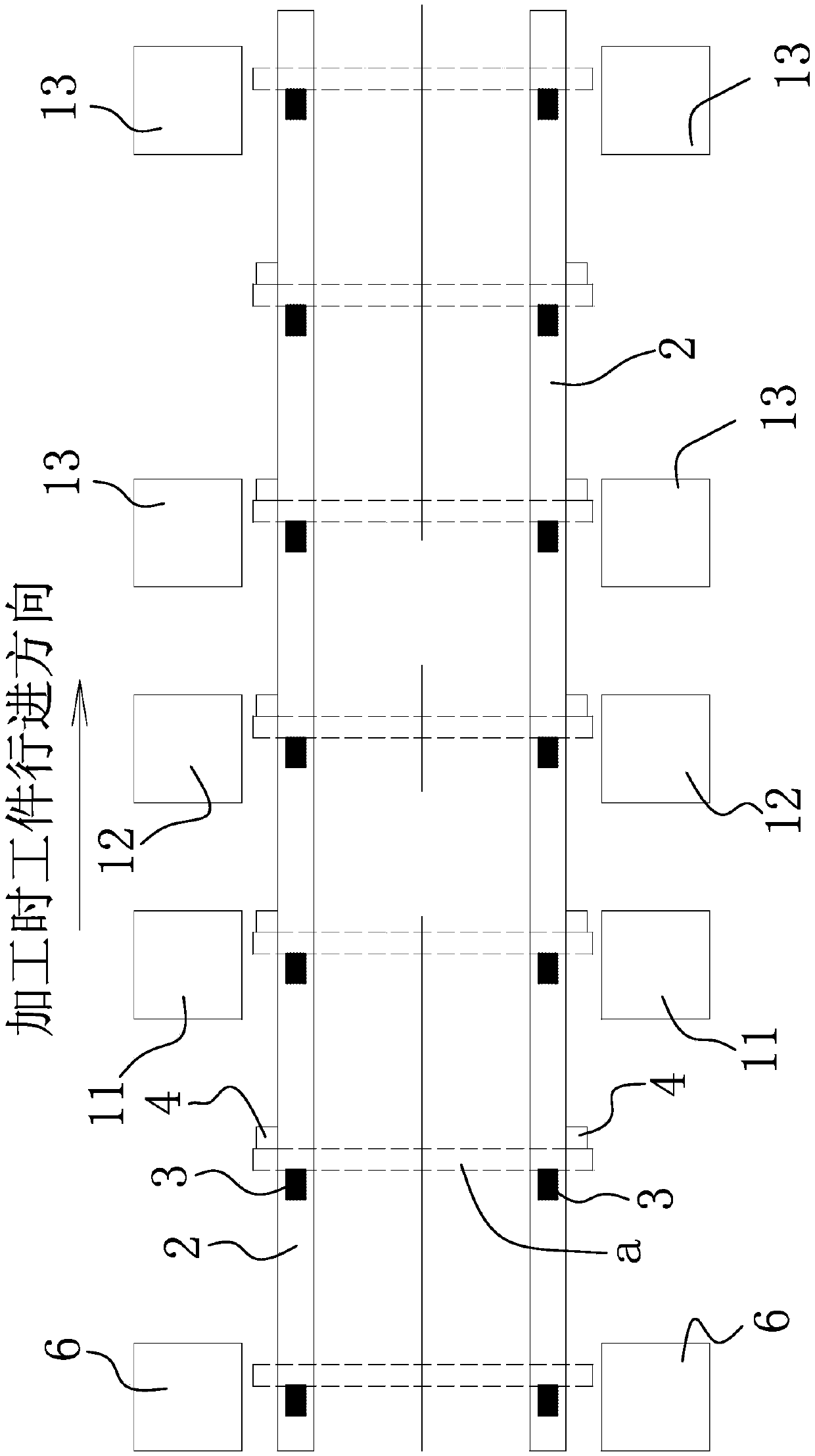

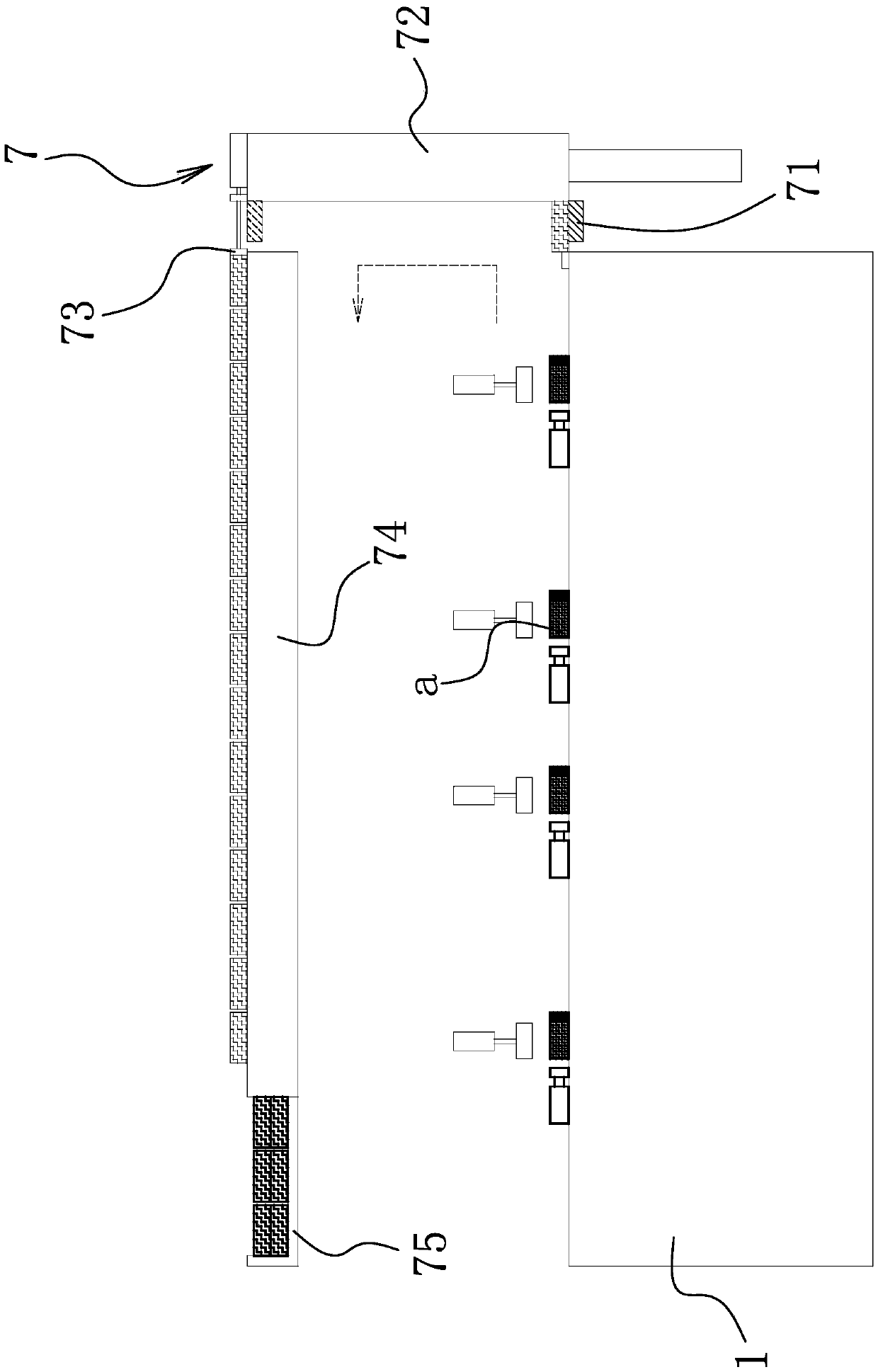

[0113] Such as Figure 8-11 As shown, the structure and principle of this embodiment are basically the same as those of Embodiment 1, so we won’t repeat them here. The difference lies in:

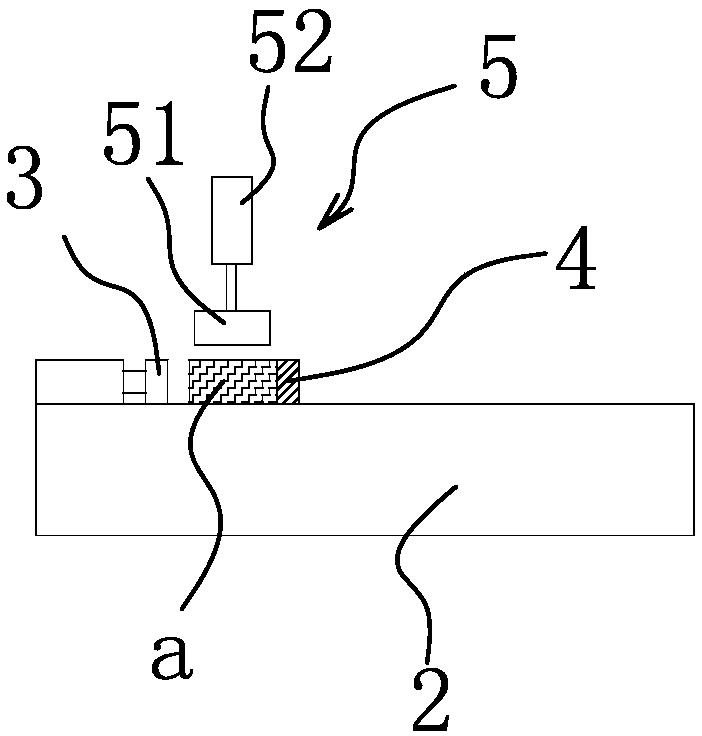

[0114] The lower tenon control mechanism 8 includes a lower tenon tube 82 arranged obliquely. The lower end of the lower tenon tube 82 is connected with a tenon planting seat 86 with a tenon silo 861 . The sliding block 87 that moves horizontally and has a wooden tenon receiving groove 871, the sliding block 87 is connected with the translation drive structure and when the wooden tenon receiving groove 871 on the sliding block 87 is aligned with the lower end of the lower tenon tube 82, the wooden The tenon receiving groove 871 receives the wooden tenon b output from the lower end of the lower tenon tube 82, and a tenon planting guide hole 862 connected with the tenon planting base 86 is provided on the tenon planting base 86, and a tenon planting guide hole 862 connected with the tenon pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com