Double-layer air cylinder special for one-nozzle multi-head structure

A double-layer cylinder and multi-head technology is applied in the field of hot runner molds, which can solve the problems of hot melt adhesive leakage, small driving force, and difficulty in providing and maintaining the glue outlet of the hot split nozzle, so as to achieve the effect of avoiding leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in combination with specific embodiments.

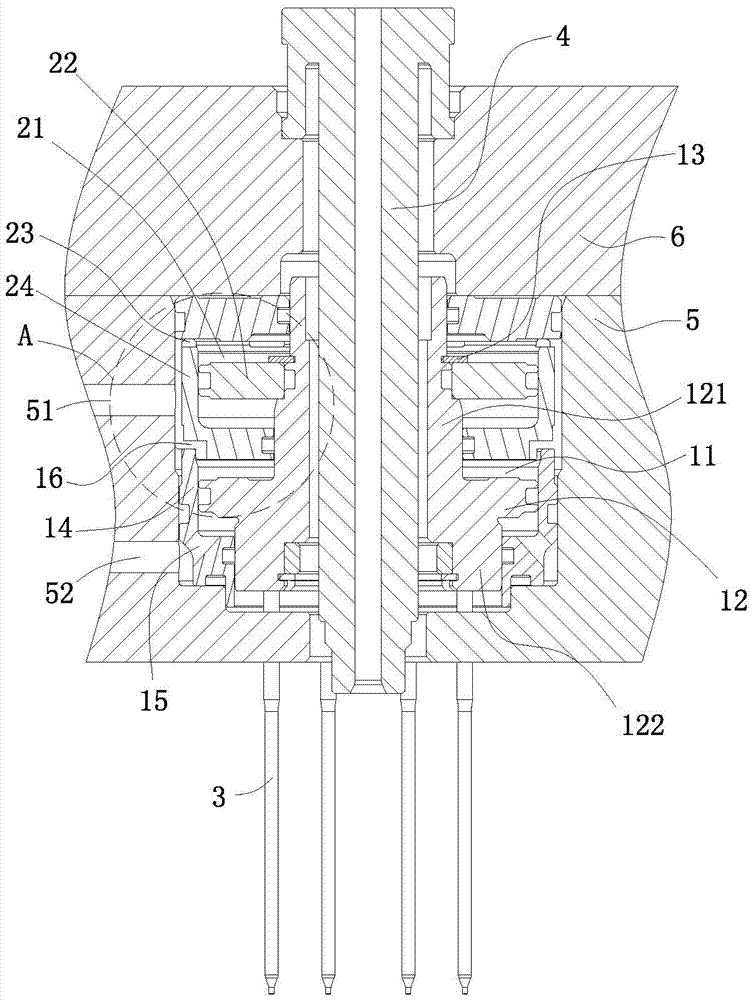

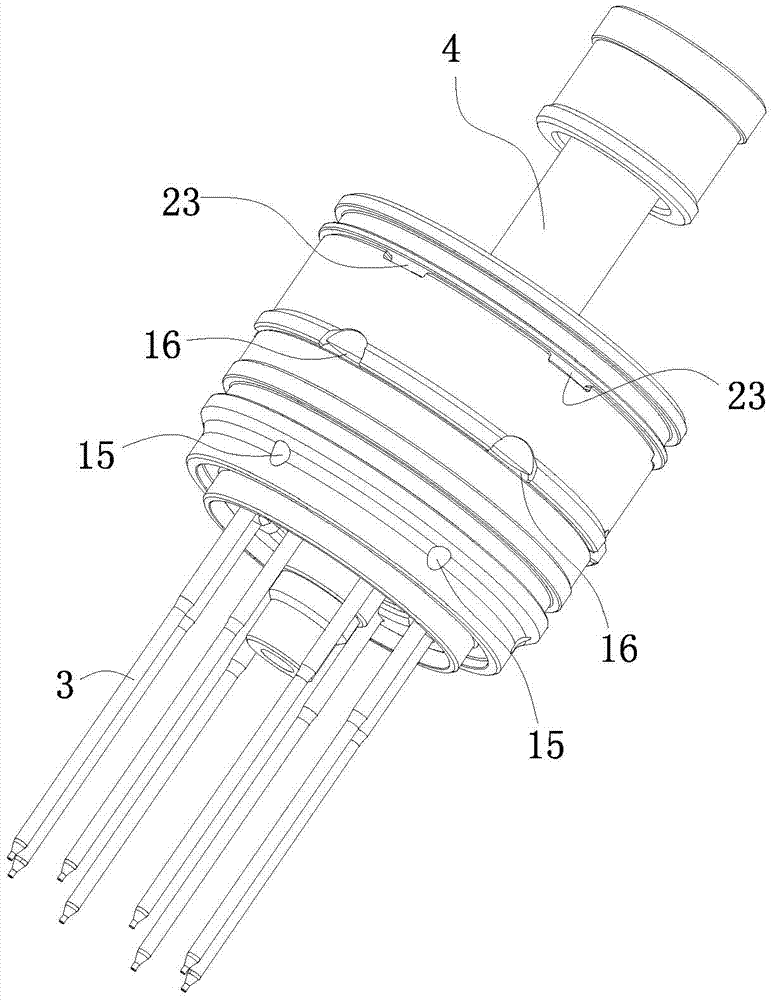

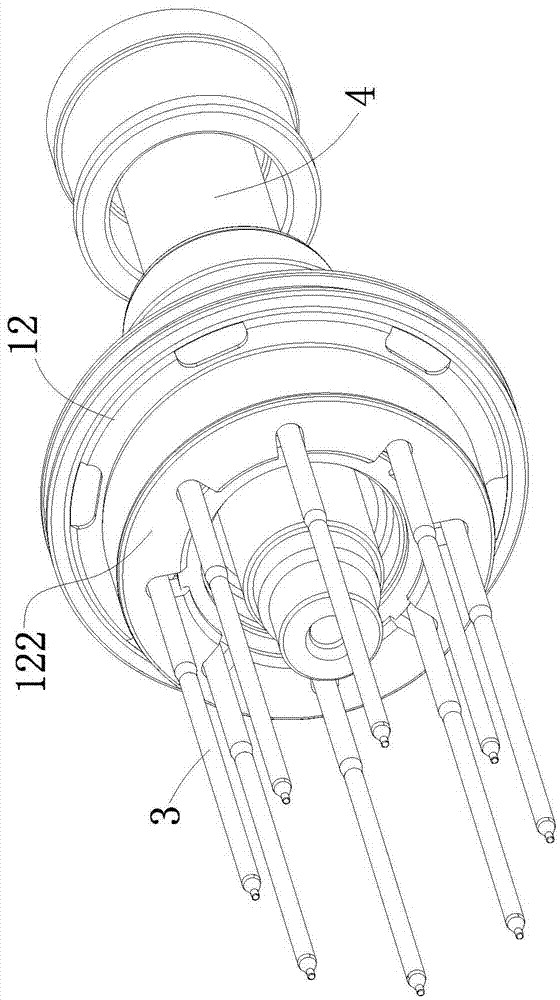

[0026] See figure 1 , figure 2 , the one-mouth multi-head dedicated double-layer cylinder provided by the present invention is installed in the first hot runner plate 5 , and the second hot runner plate 6 is also covered on the first hot runner plate 5 . The one-mouth multi-head special-purpose double-layer cylinder provided by the present invention includes a cylinder body, and a main air chamber 11 and a booster air chamber 21 are arranged in the cylinder body independently of each other. The main air chamber 11 is provided with a main piston 12 , and the pressurized air chamber 21 is provided with a booster piston 22 . The booster piston 22 is arranged coaxially with the main piston 12 and fixedly connected to each other. The main piston 12 or the booster piston 22 is fixedly connected with several valve needles 3, and each valve needle 3 is respectively used to coope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com