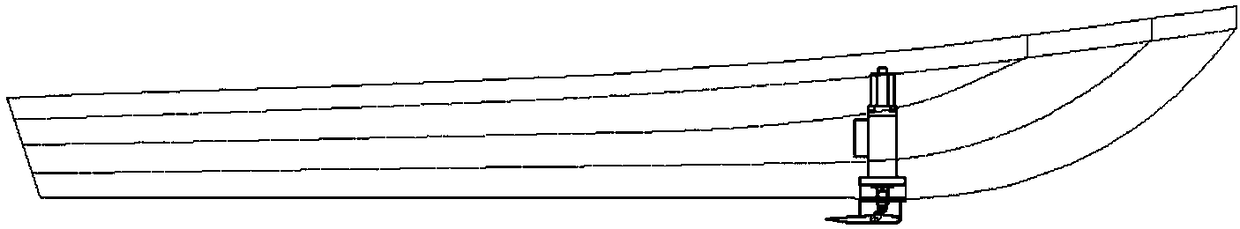

A hydraulically driven anti-pitch t-shaped hydrofoil with controllable angle of attack

A drive-type, pitch-stabilizing technology, applied in the direction of using hydrofoils to act on the surrounding water surface to reduce ship motion, etc., can solve problems such as poor integrity, difficult maintenance, harshness, etc., to improve the anti-rolling effect, ensure control accuracy, and enhance stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

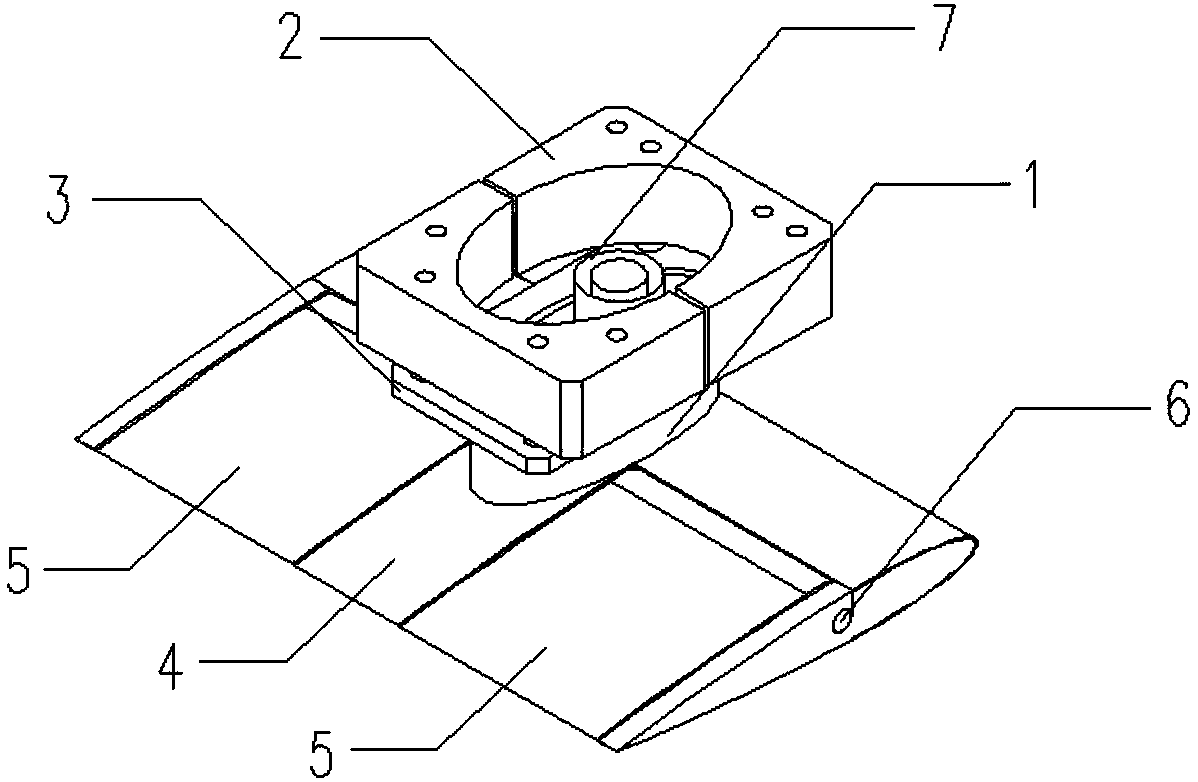

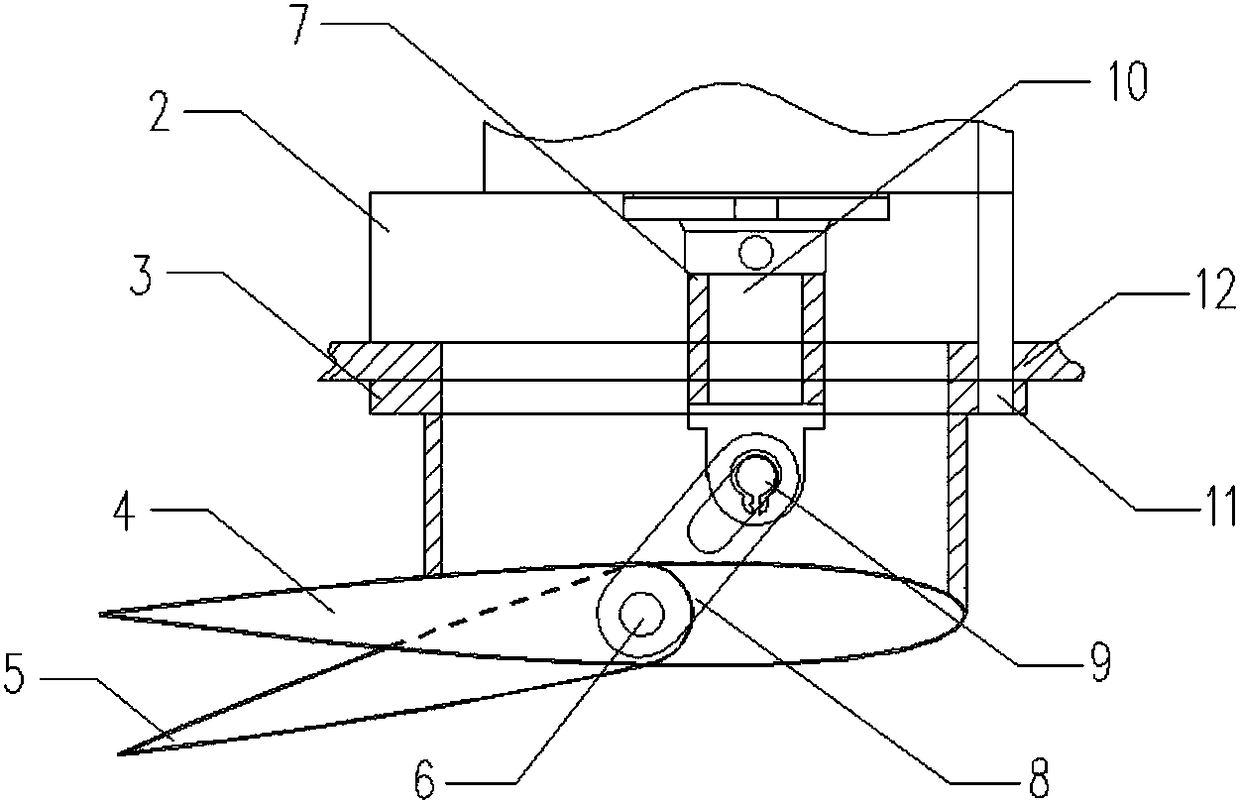

[0022] The overall technical solution is that the T-shaped hydrofoil is driven by a hydraulic cylinder, and the expansion and contraction of the piston rod of the hydraulic cylinder is converted into the synchronous deflection of the two flap tails through the mechanical transmission components. Because the size and connection mode of each mechanical transmission component are fixed, the expansion and contraction of the piston rod There is a quantitative relationship between the amount and the deflection angle α of the flap tail. A displacement sensor is installed on the piston rod to measure the expansion and contraction of the piston rod. By controlling the expansion and contraction of the piston rod, the semi-closed-loop control of the T-shaped hydrofoil angle of attack α can be realized. Thereby obtaining the expected pitching and heave righting moments. The present invention will be further described in detail below in conjunction with the accompanying drawings and specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com