Test method for testing derrick strength

A test method and derrick technology, applied in the direction of applying stable tension/pressure to test material strength, strength characteristics, measuring devices, etc., can solve the problem that the loading load cannot be placed under the derrick, so as to reduce the difficulty of the test and make the test site flexible , the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

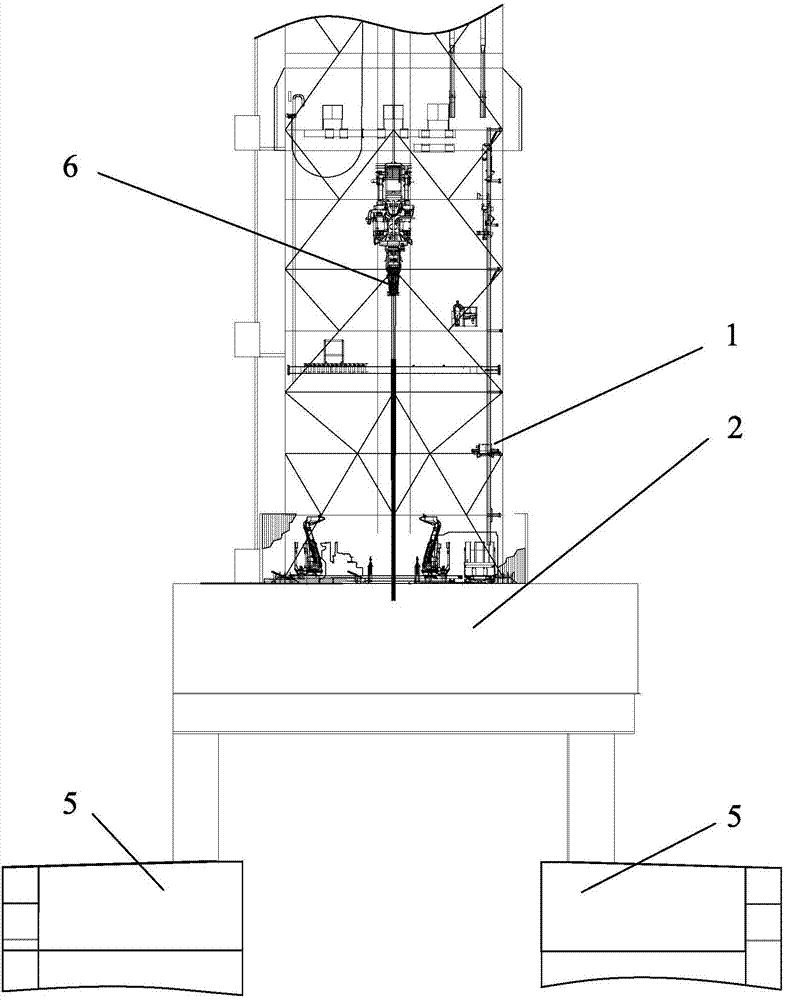

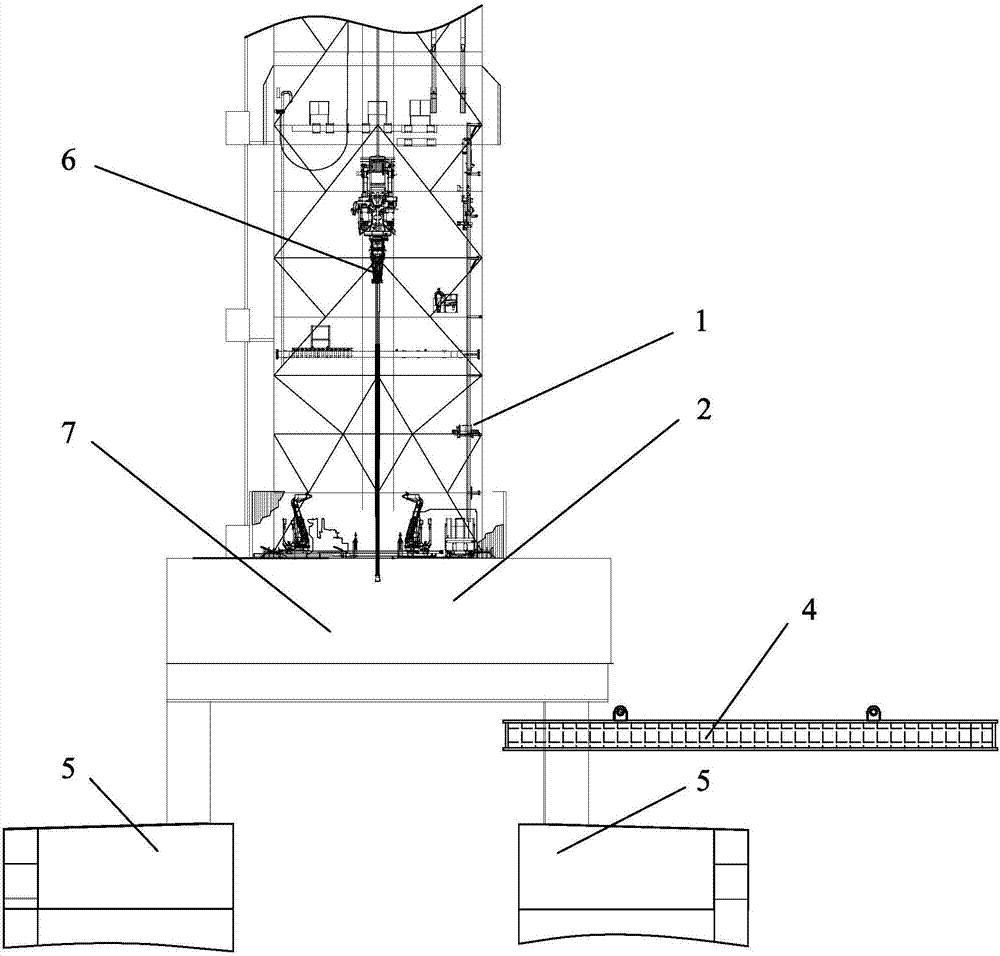

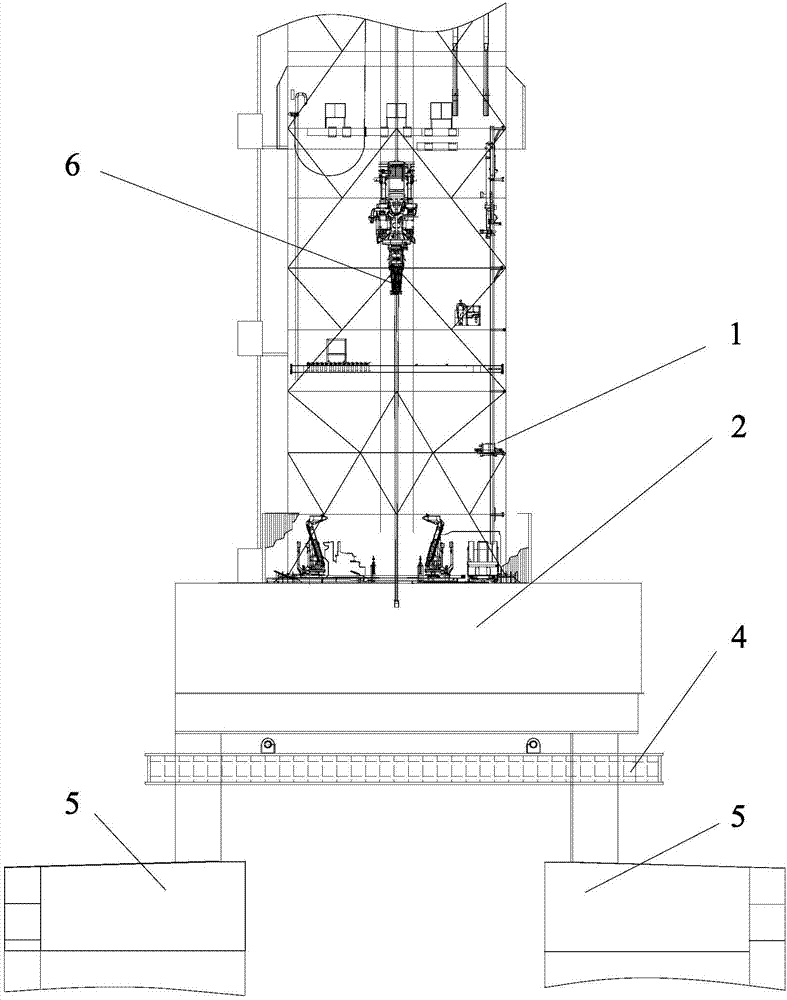

[0021] The counter support device for testing the strength of the derrick includes: a pressure sensor 3, a counter support 4, and a large-tonnage sling 7. The specific installation method: such as figure 1 As shown, the reaction force support 4 is a strong beam structure, which is installed below the drill floor 2, and pressure sensors 3 are installed at both ends of the contact portion between the upper panel of the reaction force support 4 and the lower panel of the drill floor 2 . Large-tonnage slings 7 are arranged on the reaction support, and large-tonnage slings 7 are connected with the hook 6 in the derrick.

[0022] The specific method of use: such as Figure 1~5 In the shown process, when doing the derrick strength test, the reaction support 4 is used as the hoisting load of the hook 6 in the derrick. Lift the hook, and the hook applies a load to the reaction support 4 through the large-tonnage sling 7 . At this time, the reaction force support transmits the force ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com