Working machine

一种作业、机器的技术,应用在机器/发动机、机动车、机械设备等方向,能够解决发动机控制器不能处理等问题,达到降低燃料消耗的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

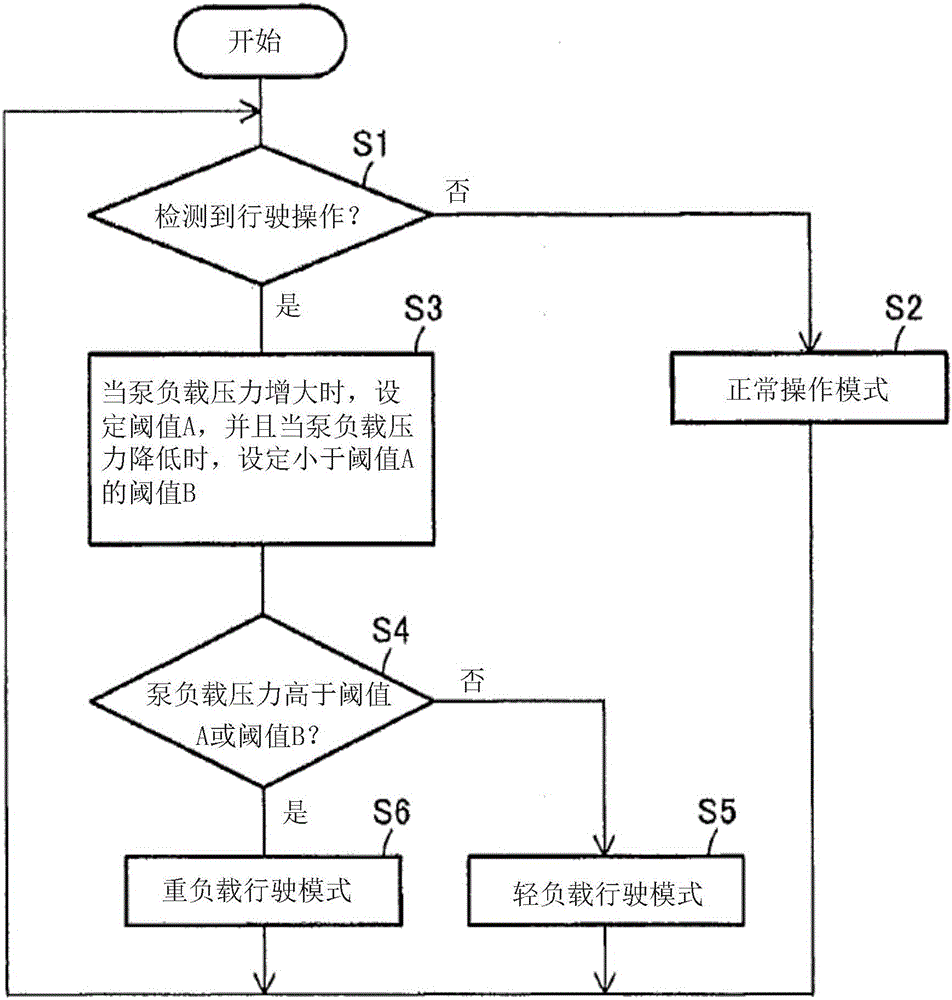

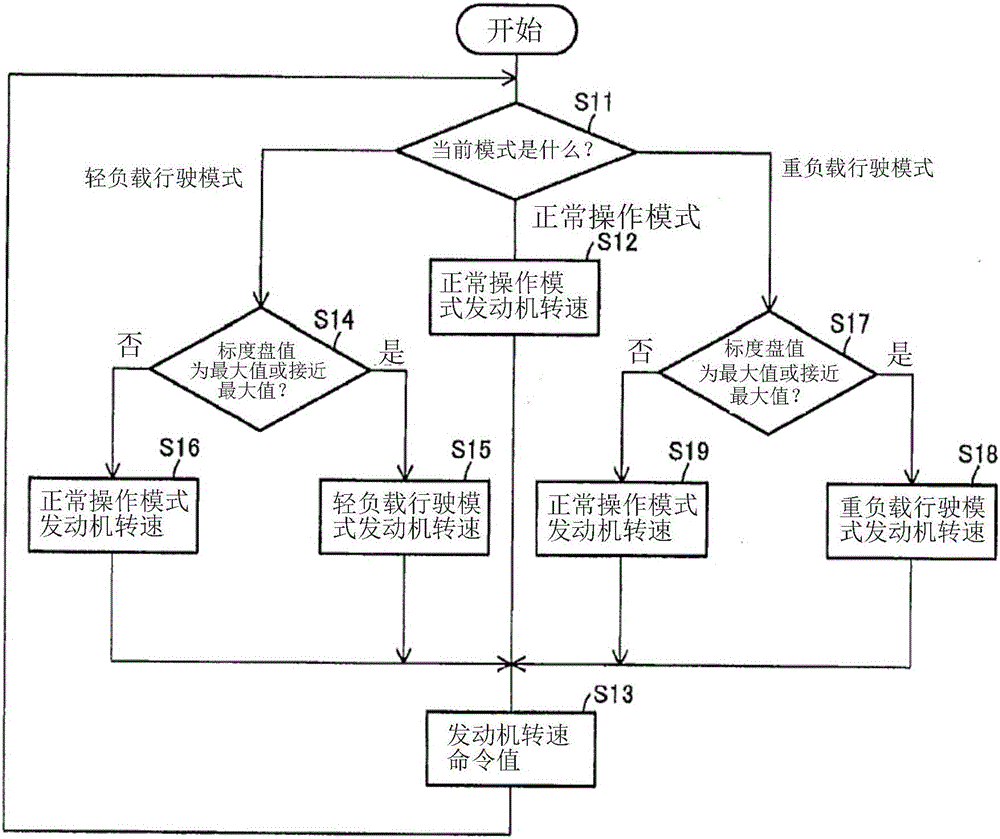

[0029] In the following, the Figure 1 to Figure 6 The examples shown in the present invention are described in detail.

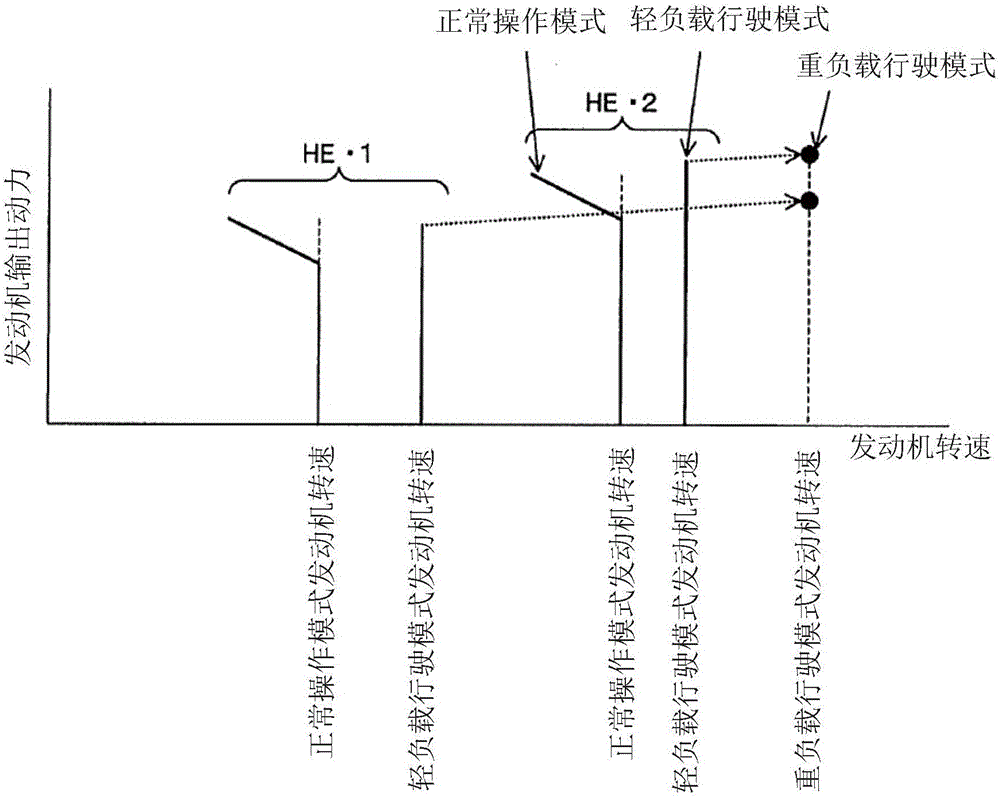

[0030] In this embodiment, the case where the engine speed is set such that (normal operation mode engine speed)<(light load running mode engine speed)<(heavy load running mode engine speed) is described by way of example. However, it is not necessary to set the engine speed so that the light load running mode engine speed is between the normal operation mode engine speed and the heavy load running mode engine speed. The engine speed may be set such that (light load running mode engine speed)≦(normal operating mode engine speed)<(heavy load running mode engine speed) or (normal operating mode engine speed)<(heavy load running mode engine speed) ≤ (light load driving mode engine speed). However, no description of these situations is provided.

[0031] The engine speed can be set such that when the pump flow rate is prioritized (normal operating mode engin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com