Device for thermoforming containers having translational mould blocks

A thermoforming and mold technology, applied in the field of container devices, can solve the problems of complex structure, limited size, and complex structure of label insertion blocks, and achieve the effects of increased productivity, high productivity, and simple movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

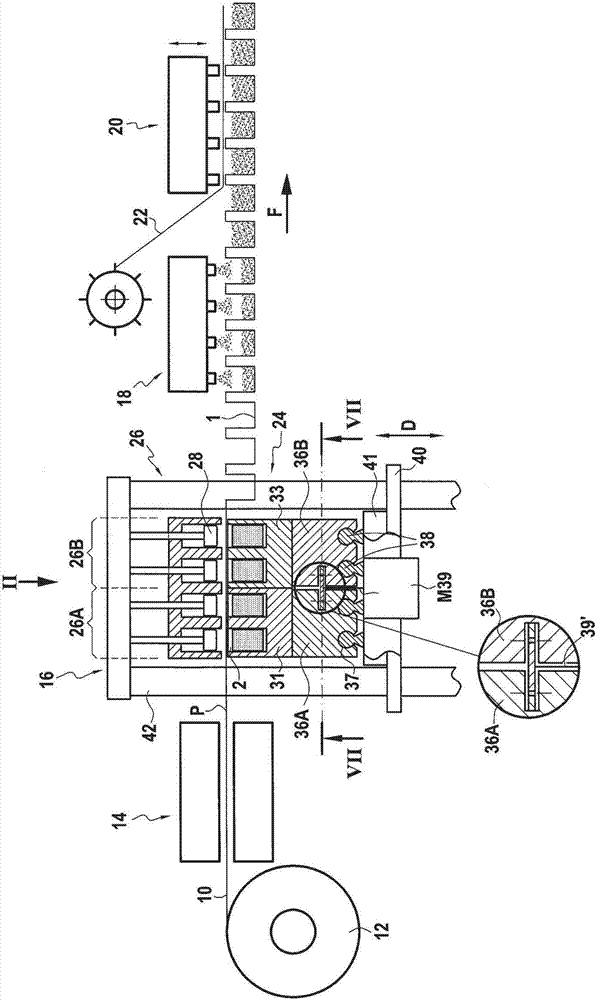

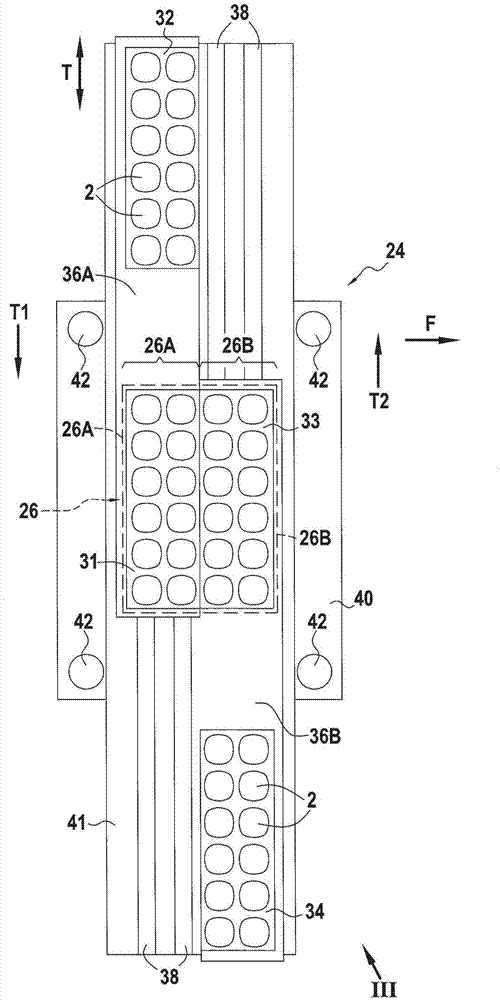

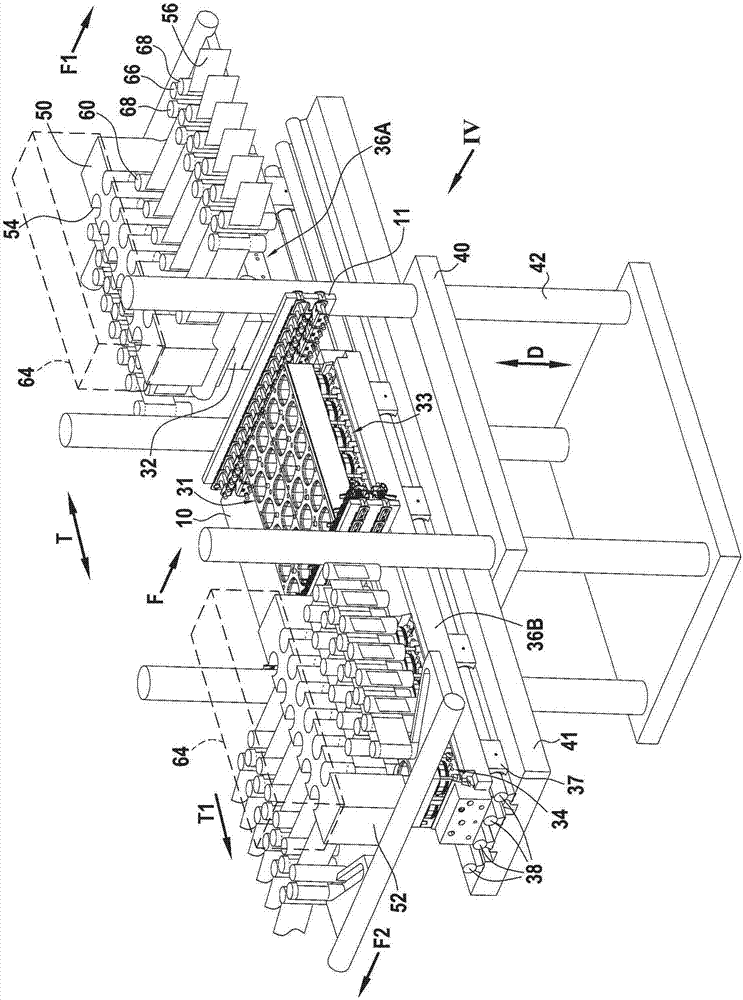

[0054] first of all, yes figure 1 Be explained, figure 1 A device for using the apparatus of the invention and for carrying out the method of the invention is schematically shown.

[0055] The plant comprises a plurality of stations through which the strip of thermoplastic material 10 is driven in sections by drive means (not shown in the figure). In the apparatus shown by way of example, the container is thermoformed from thermoplastic material in the form of a strip. Naturally, the belt can be replaced by a single sheet or panel from which the containers can be thermoformed individually or in groups, such a sheet or panel being driven in sections along the travel axis F like the belt.

[0056] Taking into account the sequence of the direction of travel of the belt traveling along the axis of travel F, the plant comprises: a heating station 14; a thermoforming station 16; a filling station 18 for filling thermoformed containers 1; and a closing station 20 for closing Conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com