Explosion-proof septic tank

A technology for septic tanks and clapboards, applied in anaerobic digestion treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as fullness and overflow of feces, prevent explosions and hurt people, and use Good effect and simple structure

Pending Publication Date: 2017-10-20

余紫阳

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

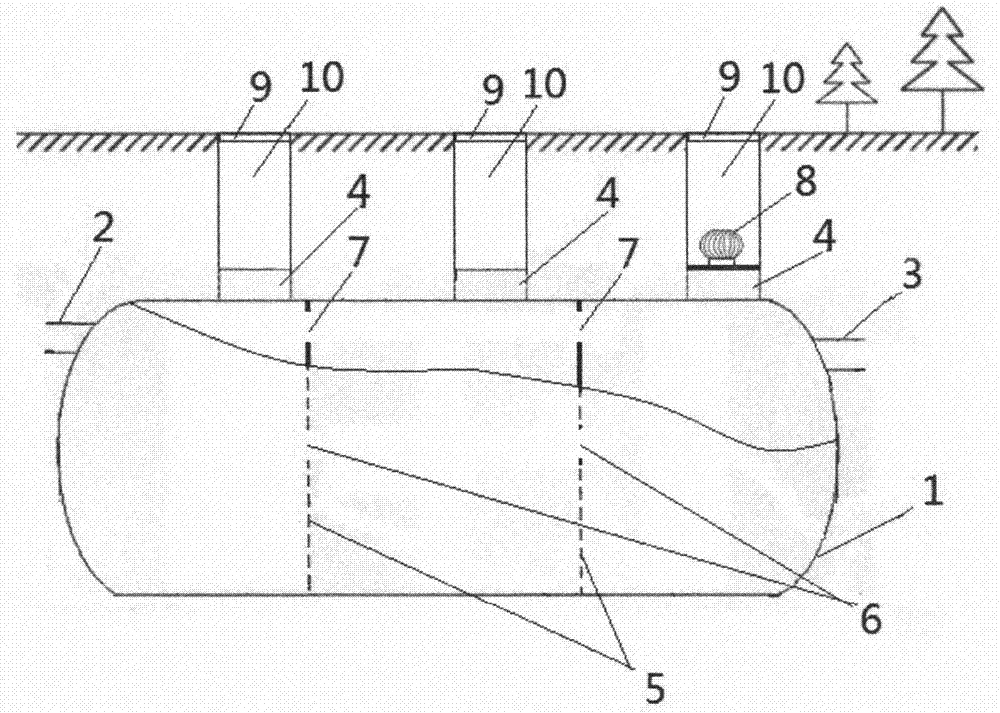

[0004] The present invention is realized like this, as attached figure 1 As shown, it is respectively provided with one or more ventilation holes (7) above the water hole (6) of the septic tank (1) clapboard (5), so that even if the water passing through the middle part of the septic tank clapboard (5) The hole (6) is blocked by sludge, and the feces in the septic tank can still be discharged into the sewer from the water outlet (3) through the air hole (7), which can improve the septic tank water hole (6) that is easily blocked by sludge. Blockage causes the problem of fecal liquid overflowing; it is provided with a plurality of ventilation holes with a diameter of more than 2cm on the well cover (9) to facilitate the internal and external air circulation of the septic tank. The ventilation hole (7) that top is provided with respectively can keep the air in three lattice septic tanks (1) unobstructed, is provided with wind cap (8) on the clearing hole (4) in the clearing well (10), " wind cap ( The working principle of the automatic ventilation ball) is to use the wind force to drive its arc-shaped fan blade turbine to rotate to cause the air convection in the structural environment, which can change the air flow into a vertical air flow from bottom to top". Under the action of the wind force generated by the water inlet (2) pouring into the septic tank, the hood (8) can be pushed to rotate and the air flow in the septic tank can be transformed into a vertical air flow from bottom to top, which can make the inside of the septic tank The biogas is discharged upwards through a plurality of ventilation holes with a diameter of more than 2cm in the manhole cover (9) along the clearing well (10)

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0007] figure 1 Among them, it consists of septic tank (1), water inlet (2), water outlet (3), cleaning hole (4), partition (5), water hole (6), ventilation hole (7), wind cap (8). The manhole cover (9) and the clearing well (10) are composed of a vent hole (7) above the septic tank (1) partition (5) through the water hole (6); A hood (8) is arranged on the clearing hole (4) of the cut well (10).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an explosion-proof septic tank 3. According to the explosion-proof septic tank, vent holes (7) are formed in partition plates (5), above water through holes (6), of a septic tank (1), so that the problem that liquid manure is subjected to swelling overflow due to the fact that the water through holes (6) of the septic tank are easily blocked by sludge can be solved; in addition, wind cowls (8) are arranged above clearing and raking holes (4) of clearing and raking wells (10), thus, the wind cowls (8) can be pushed to rotate and air flow in the septic tank can be changed into bottom-up vertical air flow under the action of wind generated when the liquid manure rushes in the septic tank from a water inlet (2), thus, marsh gas in the septic tank can be upwards exhausted along the clearing and raking wells (10) through a plurality of ventilation holes with the diameter of 2cm or more in well covers (9), and then, the internal marsh gas concentration of the septic tank is lowered, so that the problem that people are injured by firedamp explosion of the septic tank can be effectively prevented; and the explosion-proof septic tank is simple in structure, good in use effect and extremely easy in popularization.

Description

Technical field [0001] The present invention relates to a new kind of new explosion-proof septic tank 3, Background technique [0002] The septic tank is a three-format sewage treatment structure consisting of a first-level anaerobic chamber, a second-level anaerobic chamber, and a third-level clarification chamber. The septic tank is usually provided with water inlets, water outlets, and dregs. At present, most of the septic tanks are divided into three-cell septic tanks by partitions (partition walls), and the middle part of the septic tank partition wall is provided with a water passage (pass hole or pipe ), if the septic tank is not cleared in time, when the sludge deposited in the septic tank exceeds the height of the water passage, the sludge will block the water passage, causing the fecal liquid in the septic tank to not normally flow from the outlet of the septic tank As a result, the problem of swelling and overflowing of the septic tank is likely to occur; in addition,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F11/04C02F3/28

CPCC02F3/28C02F3/286C02F11/04C02F2203/006

Inventor 余紫阳

Owner 余紫阳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com