Sleeve-frame type limiting mechanism and limiting method for controlling lateral displacement in building lifting process

A limit mechanism and control side technology, applied in building construction, construction, building maintenance, etc., can solve problems such as excessive horizontal displacement, and achieve the effect of preventing translation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

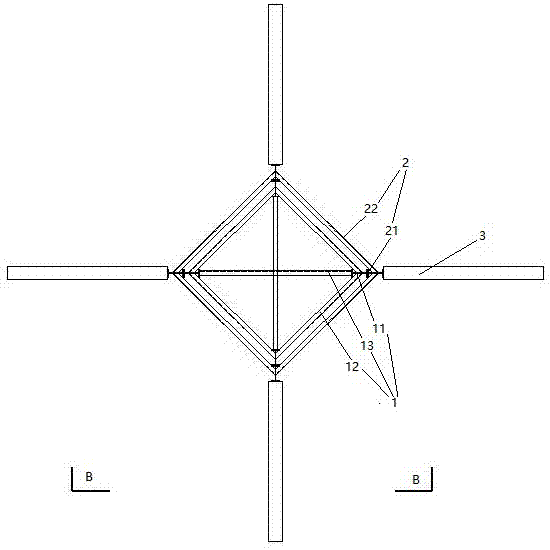

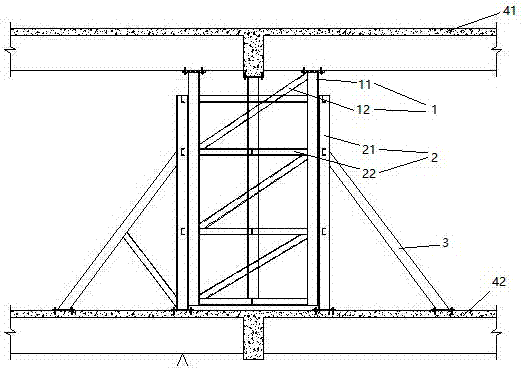

[0021] Embodiment one, see figure 1 , a sleeve-type limit mechanism for building jacking to control lateral displacement, comprising a limit column 1 and a limit sleeve 2 whose upper end is sleeved on the lower end of the limit column.

[0022] The limiting column 1 is in the shape of a quadrangular prism. The limit column 1 includes four limit column columns 11 . The post 11 of the limiting column part is a channel steel. The four space-limiting column columns 11 are distributed in a rectangular shape. The adjacent posts 11 of the limiting posts pass through several connecting rods 12 on the side of the limiting posts. The upright posts 11 of the opposite limiting posts are connected together by a plurality of internal connecting rods 13 .

[0023] The limit sleeve 2 is in the shape of a quadrangular prism. The limit sleeve 2 includes four upright posts 21 at the portion of the limit sleeve. The uprights 21 of the limiting sleeve are distributed in a rectangular shape. ...

Embodiment 2

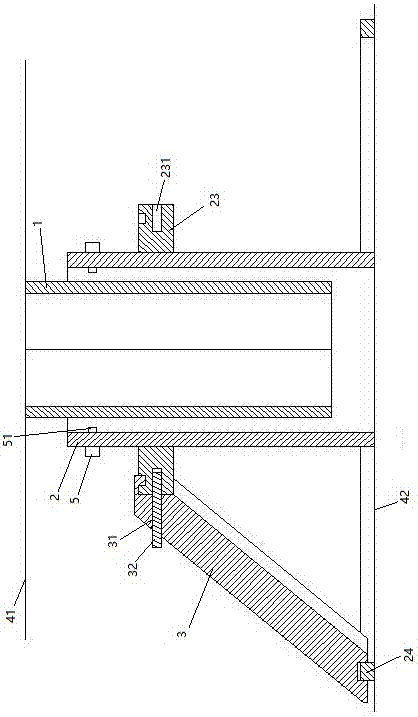

[0026] Embodiment two, the difference with embodiment one is:

[0027] see image 3 , both the limit post 1 and the limit sleeve 2 are cylindrical. The limit post 1 and the limit sleeve 2 are disconnected, and the disconnection gap is less than or equal to the displacement when translation is allowed. and are circular

[0028] The upper end of the spacer cover 2 is provided with several indicator lights 5 distributed along the circumferential direction of the spacer cover, and the distance between adjacent indicator lights along the circumferential direction of the spacer cover is 3 cm. , each indicator light 5 is respectively provided with a push switch 51 for turning on the indicator light. The push switch 51 is connected to the inner peripheral surface of the limit sleeve 2 . The push switch 51 and the indicator light 5 controlled by the push switch are distributed along the radial direction of the limit sleeve 2 . The upper end of the limit sleeve 2 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com