Hidden height increasing sole processing method

A processing method and invisible technology, applied in the direction of shoe soles, footwear, clothing, etc., can solve the problems of thick soles, easy degumming, high labor costs, etc., and achieve the effect of solving the problem of supporting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

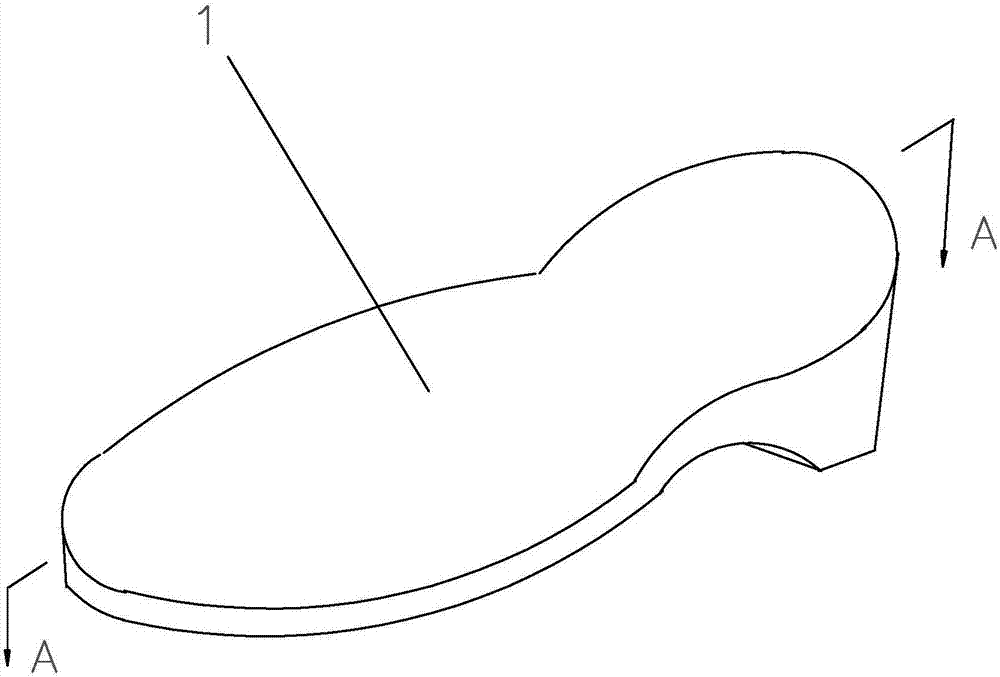

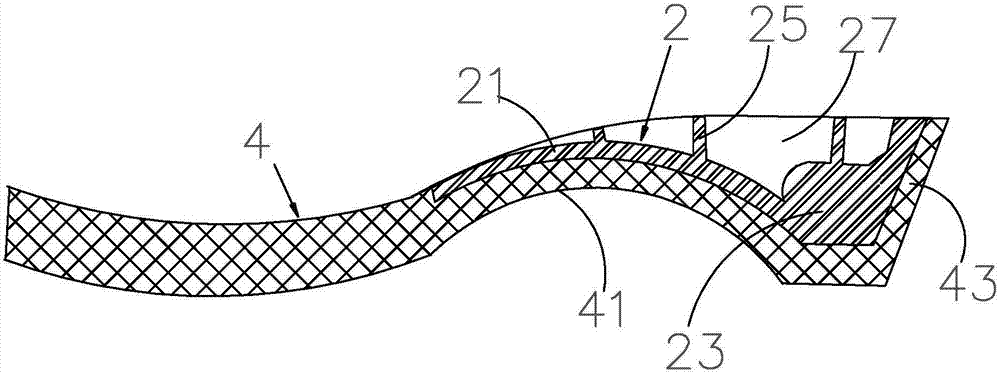

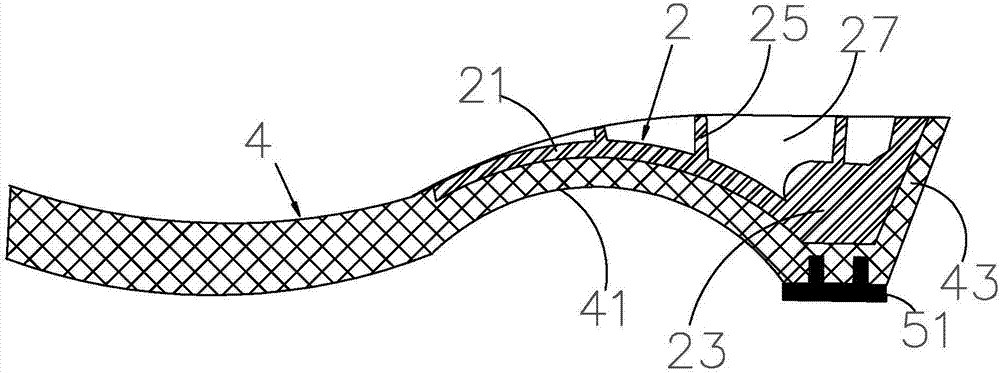

[0016] refer to Figure 1-2 , the present invention is an arched sole 1, comprising a sole main layer 4 and a support layer 2 located at the rear of the upper part of the sole main layer 4. In the present invention, the sole body layer 4 and the support layer 2 are closely attached to each other.

[0017] In the present invention, the sole main body layer 4 is made of high molecular polymer, such as rubber, thermoplastic rubber (TR, TPR), thermoplastic elastomer, polyvinyl chloride (PVC), thermoplastic polyurethane (TPU), polyurethane (PU) Made of any one or a combination of materials. refer to figure 1 , the middle part 41 of the sole main body layer 4 is arc-shaped, and its tail part 43 and the middle part 41 form a depression 46 for accommodating the support layer 2 .

[0018] Wherein, the support layer 2 can be made of metal or a polymer with high hardness (suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com