Gathering and folding type hand buggy

A hand-pulled cart and tie-rod technology, applied in the field of hand-pulled carts, can solve the problems of low space utilization rate and lack of aesthetics, and achieve the effect of high space utilization rate and beautiful structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

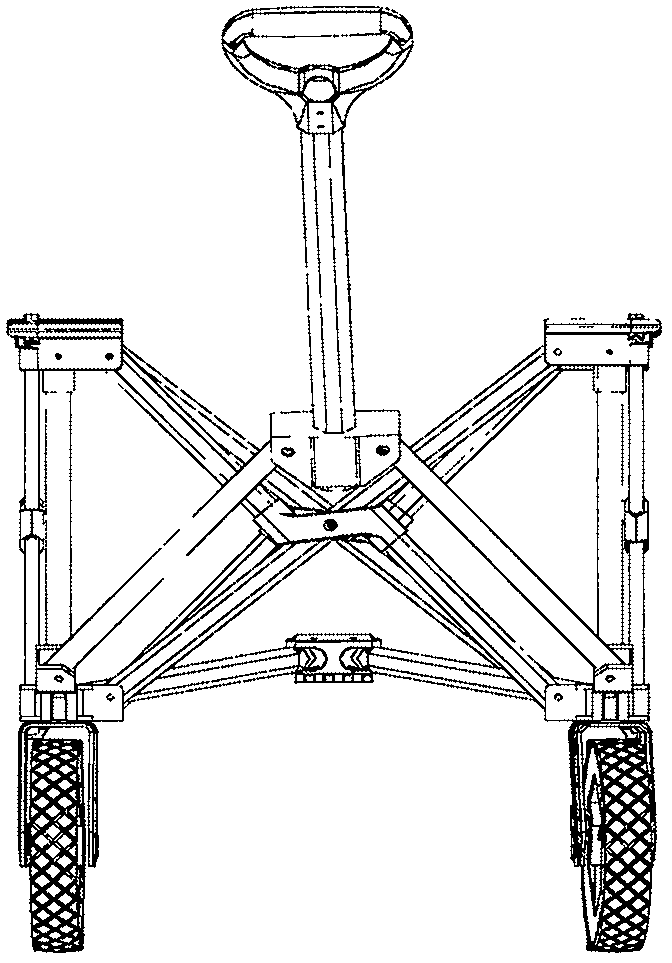

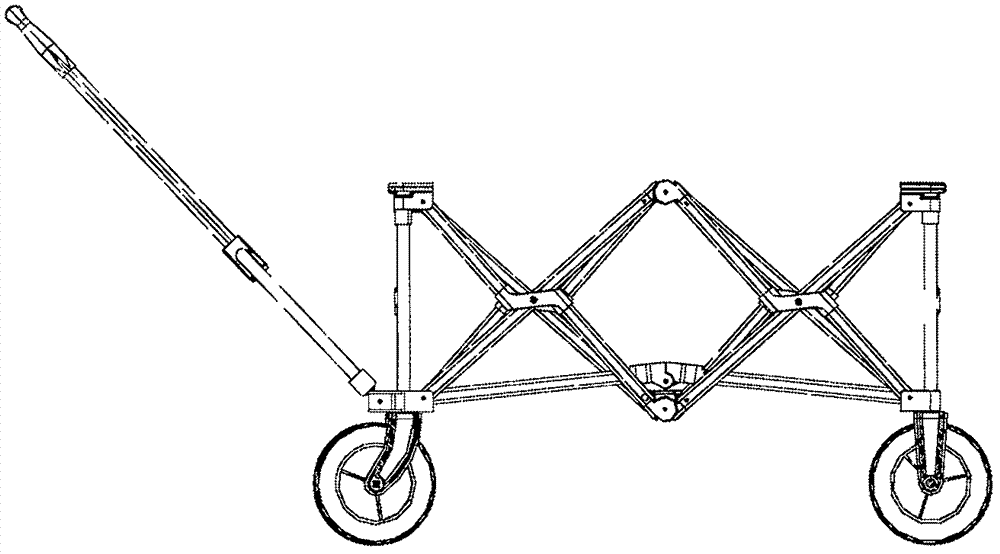

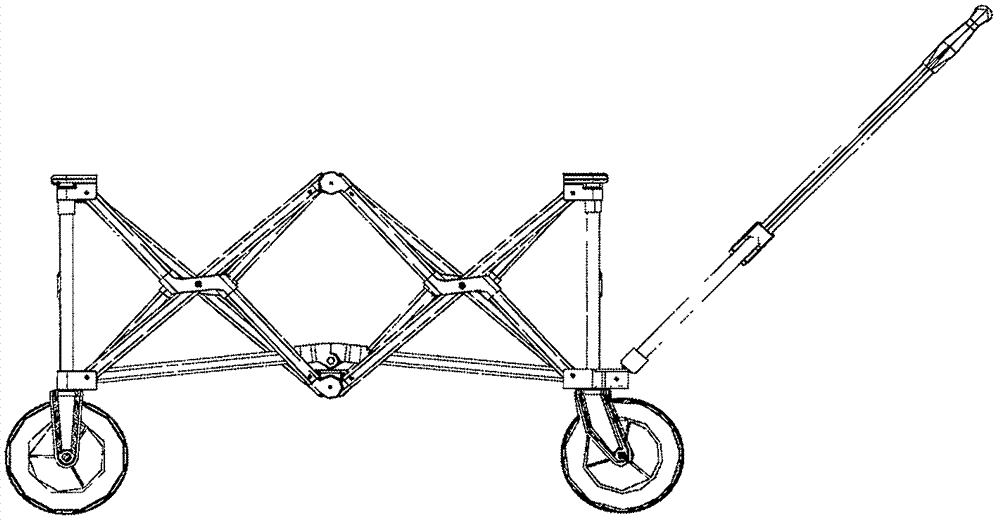

[0034] refer to Figure 1 to Figure 15 , a foldable handcart, comprising a frame assembly, a pull rod assembly and wheels, the pull rod assembly is arranged in front of the frame assembly, and the wheels are arranged at the bottom of the frame assembly, so The vehicle frame assembly includes an underframe, a front frame arranged in front of the underframe, a rear frame arranged behind the underframe, and foldable side frames arranged on the left and right sides of the underframe. X cross pipe assembly, the same plane X cross pipe assembly includes long inclined pipe 14, short inclined pipe 16 and hollow seat, the middle part of the hollow seat is provided with a long hole along the front and rear direction, the front and rear of the hollow seat 15 The two ends are respectively vertically provided with opposite pipe joints. The long inclined pipe 14 passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com