Gas cylinder tool

A tooling and gas cylinder technology, applied in the field of mobile standard gas cylinder tooling, can solve the problems of personal and working environment damage, many types of harmful gases, and air leakage, and achieve the effects of improving work efficiency, facilitating transportation, and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

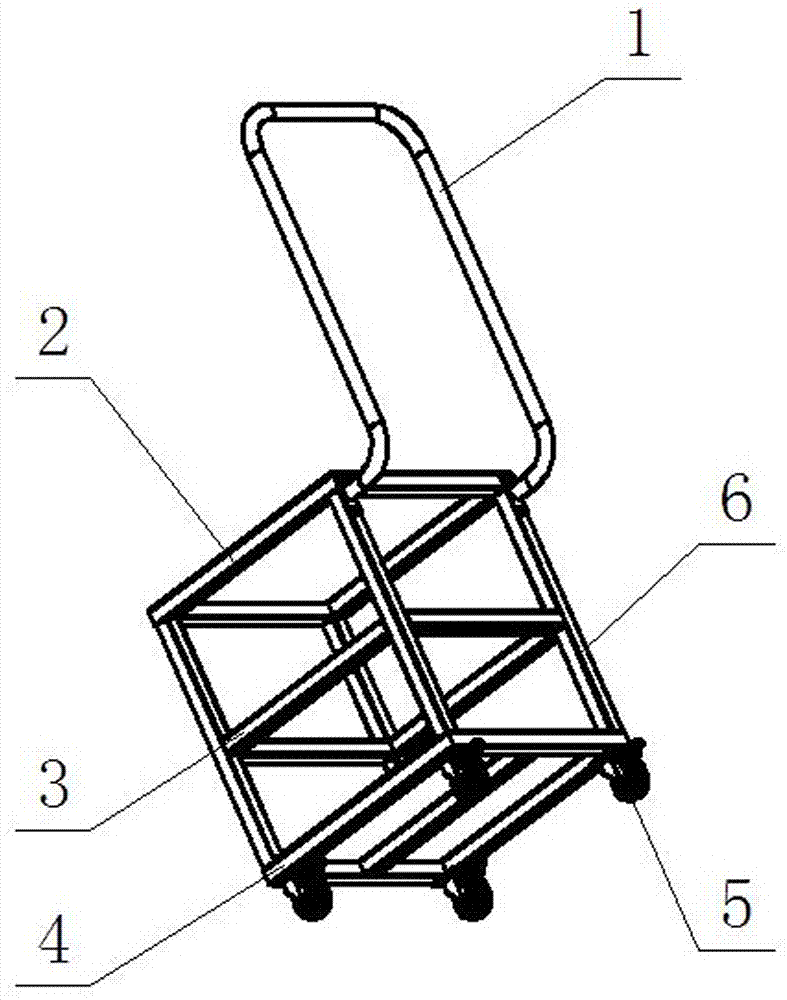

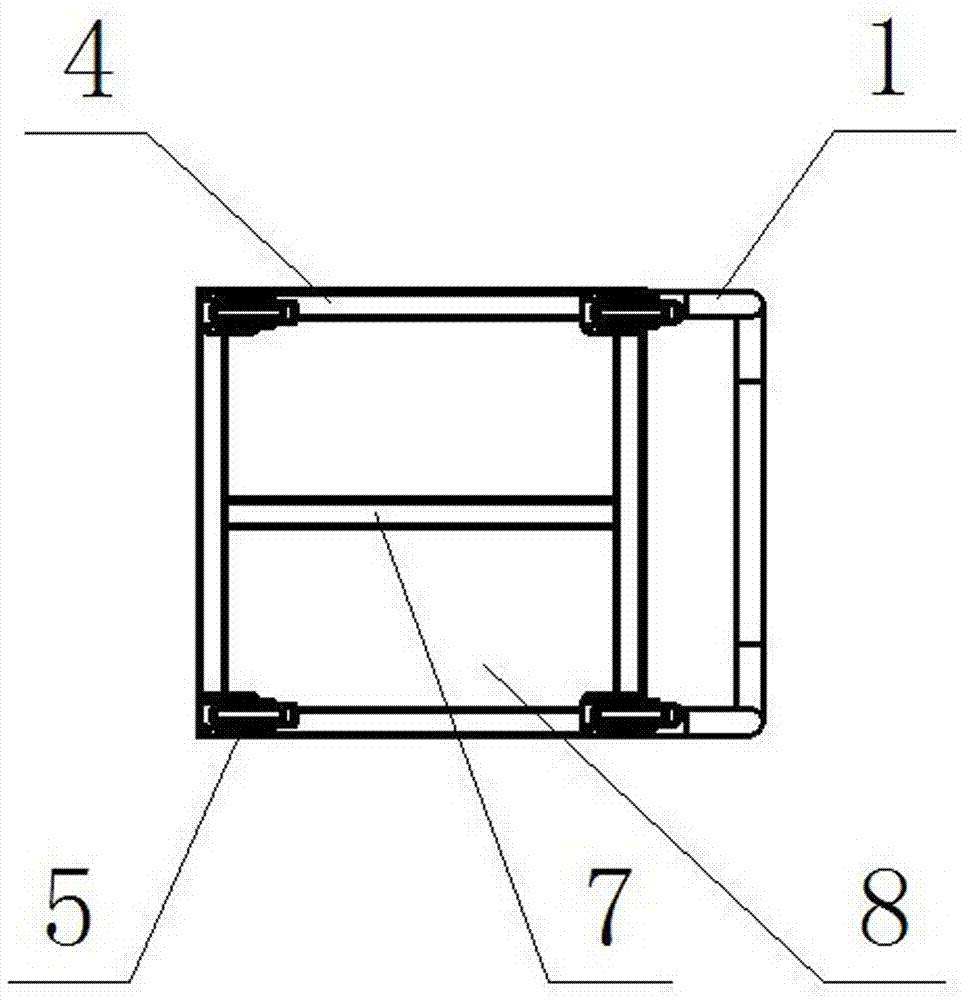

[0012] Specific implementation mode one: A gas cylinder frock, comprising Uplink frame (2), BOC frame (3), Downlink frame (4) , characterized in that: the uplink frame ( 2 ) and the down frame ( 4 ) through the vertical frame ( 6 ) connection, the uplink frame ( 2 ) and the down frame ( 4 ) between the BOC frame ( 3 ), the Bank of China framework ( 3 ) connected around the vertical frame ( 6 ) on; the uplink frame ( 2 ) with a handle on one side ( 1 ); the downlink frame ( 4 ) with multiple universal wheels at the bottom; the descending frame ( 4 ) internally with reinforcing beams ( 7 ); the reinforcing beam ( 7 ) above the bottom plate ( 8 ); the bottom plate ( 8 ) connected around the downlink frame ( 4 ) inner frame 。

[0013] The handle ( 1 ) soldered on the upstream frame ( 2 ) side.

[0014] said The uplink frame (2), the middle row frame (3), the downlink frame (4) and the vertical frame (6) are all ...

specific Embodiment approach 2

[0016] like figure 1 As shown, the gas cylinder tooling is composed of a handle (1), an upward frame (2), a middle frame (3), a downward frame (4), universal wheels (5) and a vertical frame (6). The handle (1) is welded to the side of the ascending frame (2).

specific Embodiment approach 3

[0017] Specific implementation mode three: as figure 2 As shown, the main frame is composed of an uplink frame (2), a middle row frame (3), a downlink frame (4) and a vertical frame (6) welded.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap