A belt conveyor tail linkage locking device

A locking device and belt conveyor technology, applied in the conveyor control device, transportation and packaging, conveyor objects, etc., can solve problems such as accidents and belt conveyors are prone to accidents, and achieve the effect of avoiding restarts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

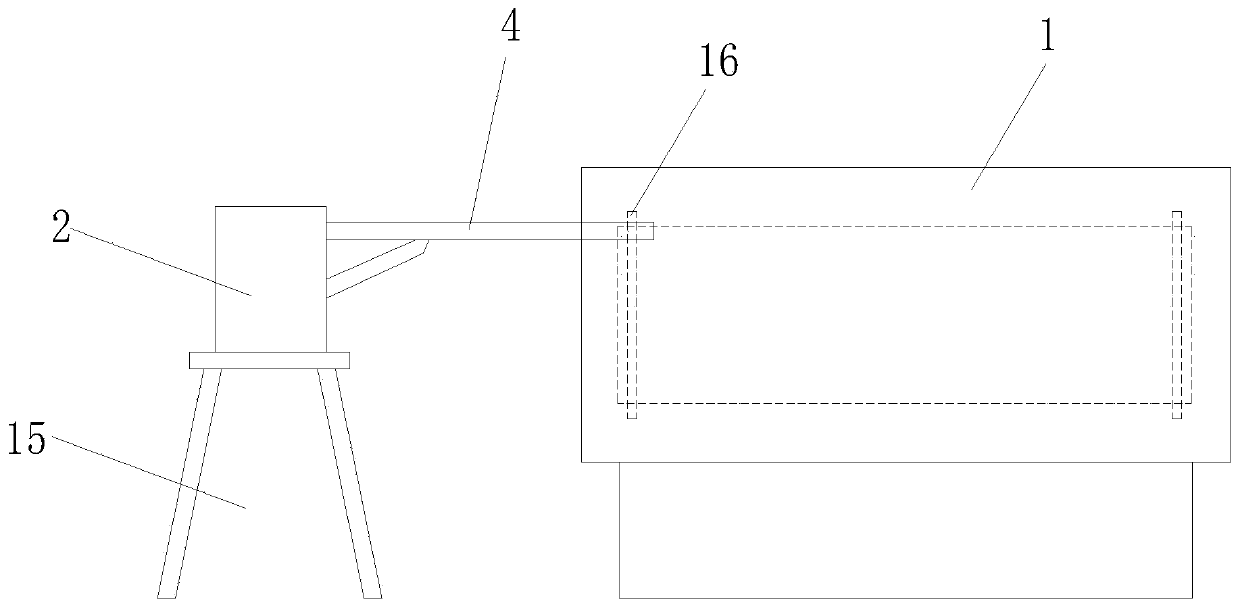

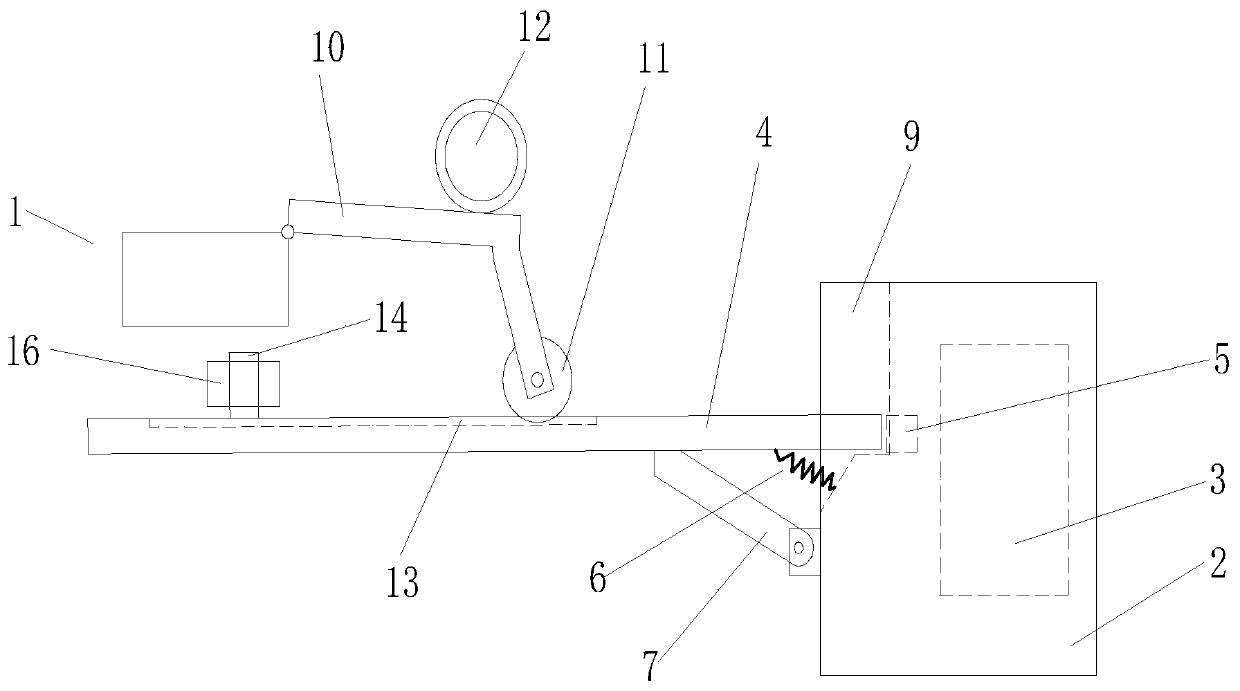

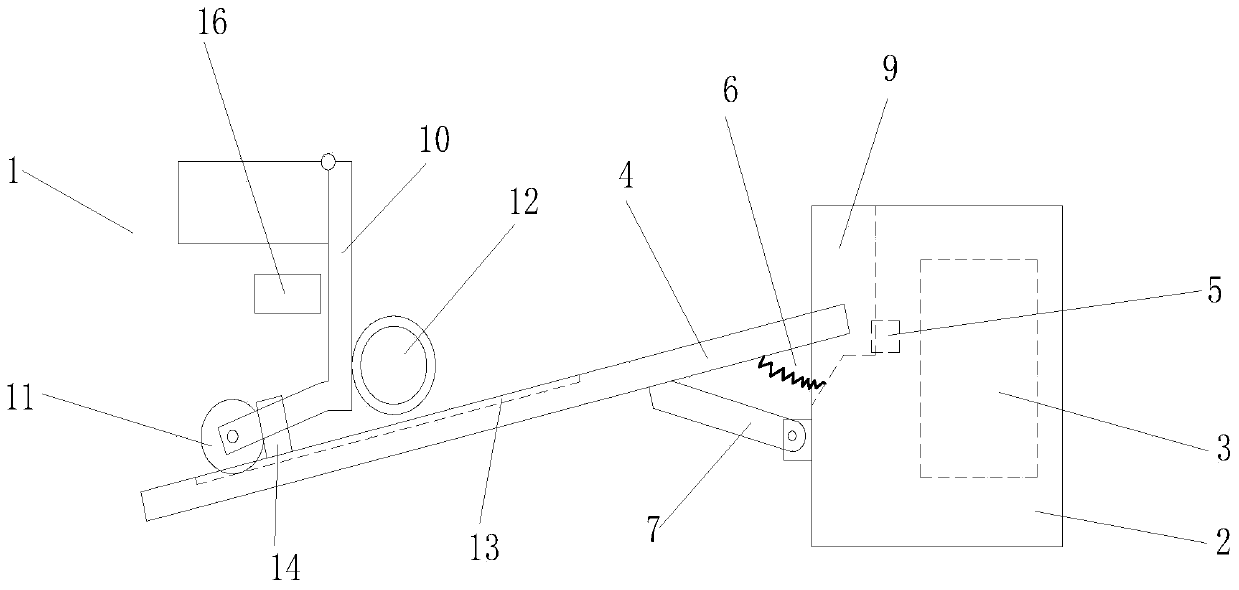

[0017] figure 1 , figure 2 , image 3 and Figure 4 A specific embodiment of the present invention is shown: a belt conveyor 1 tail linkage locking device, the device is arranged at the tail of the belt conveyor 1, the device includes a housing 2, a controller 3 built in the housing 2, a contact The swing rod 4 and the sensor 5 are provided with a support frame 15 at the bottom of the housing 2, the contact swing rod 4 is hinged relative to the housing 2, and a telescopic structure 6 is arranged between the contact swing rod 4 and the housing 2. The controller 3 of the device It is connected with the emergency stop button along the belt conveyor 1 and the head operating system of the belt conveyor 1. The belt conveyor 1 is provided with a trigger device. The snap-in end is provided with positioning latch teeth 14 .

[0018] The trigger device starts, and the clamping end of the contact swing rod 4 is stuck at the chain 16 of the belt conveyor 1 under the action of the tel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com