A vibration protection method for a centrifuge

A centrifuge and vibration speed technology, applied in centrifuges and other directions, can solve the problems of corrosion and cumbersome parts of the slag discharge part, and achieve the effect of reducing maintenance manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific embodiments of the present invention are described in detail below.

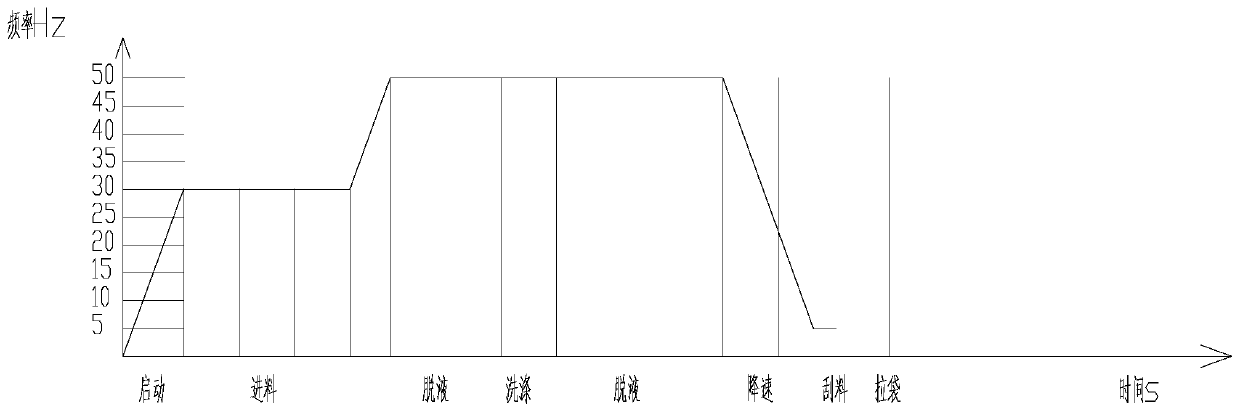

[0034] A vibration protection method for a centrifuge, comprising setting a vibration measurement sensor and an alarm device on the centrifuge casing that are electrically connected to the control device and installed on the inner side of the casing at a position facing the middle of the drum wall, and then the control device according to The measured value of the sensor controls the main motor of the centrifuge as follows:

[0035] 1) During the whole feeding, washing and dehydrating process: if the vibration speed measured by the vibration measurement sensor is Fr<25mm / s, the centrifuge operates according to the set procedure;

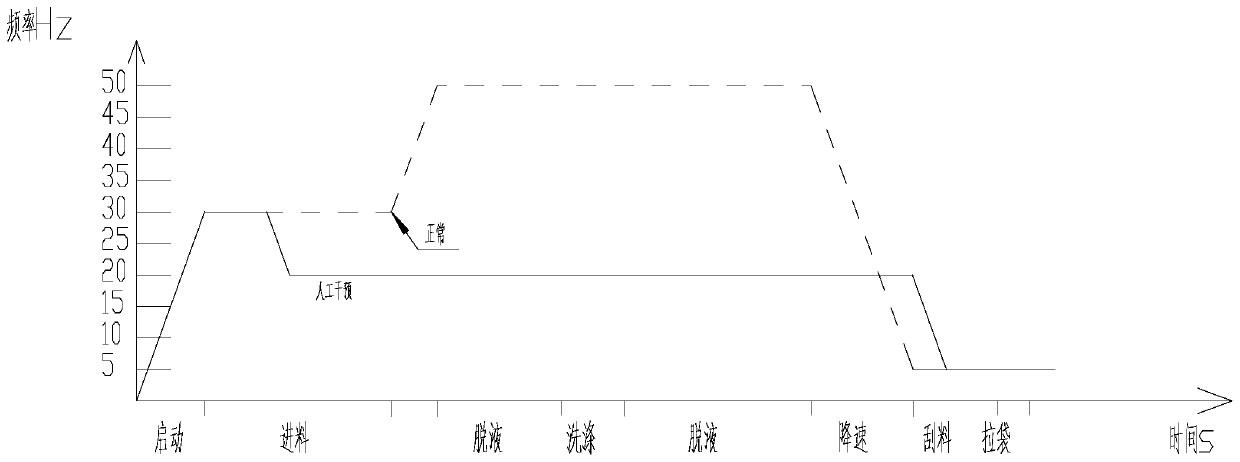

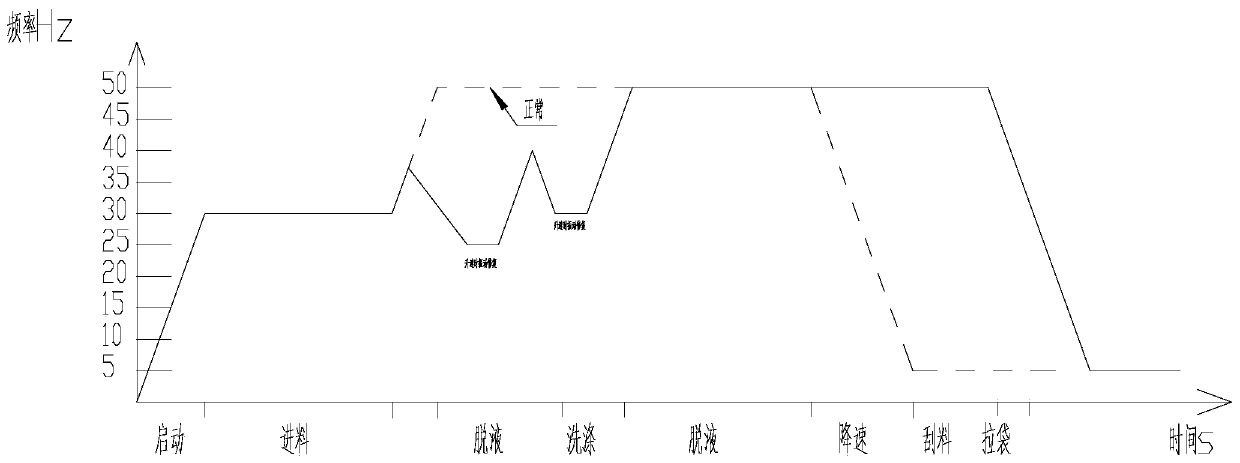

[0036] 2) During the feeding process:

[0037] If the vibration measurement sensor measures the vibration speed Fr ≥ 25mm / s, the feeding is turned off, the control device controls the operating frequency of the main motor to drop by 10Hz, the control device control...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap