Device for transferring and hoisting heavy equipment

A technology of heavy equipment and hoisting device, applied in the field of machinery, can solve the problems affecting the maintenance time of the overhaul end face, the fixed pollution of the equipment body, and the heavy weight of the single equipment, so as to reduce the collective and individual doses of personnel, shorten the maintenance and transfer time, and reduce the The effect of maintenance manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

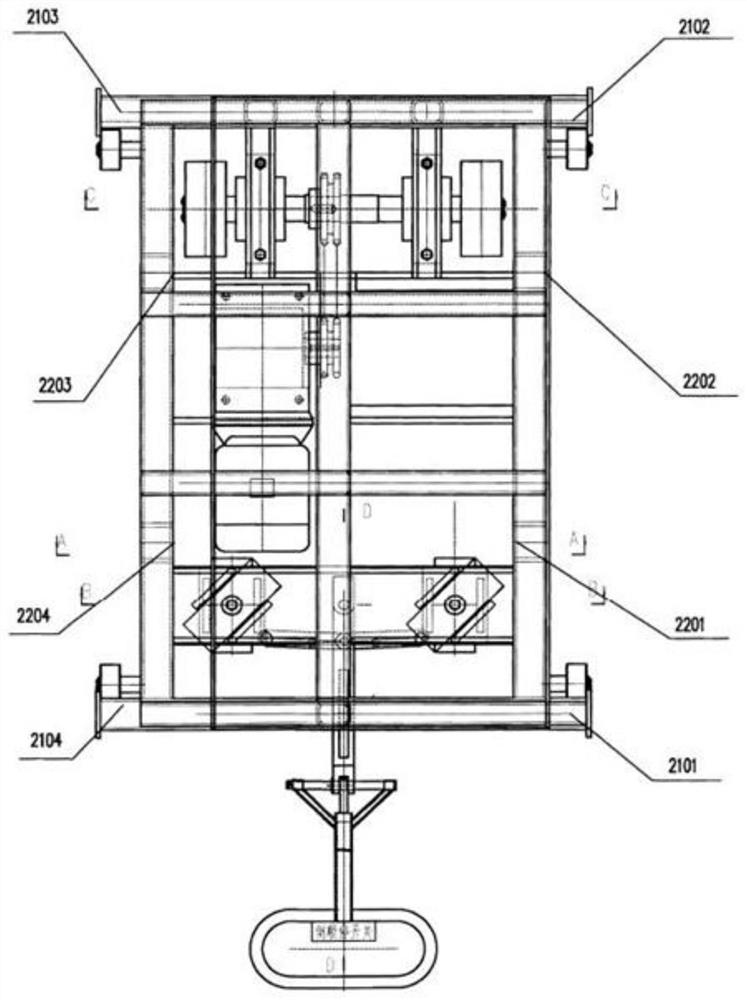

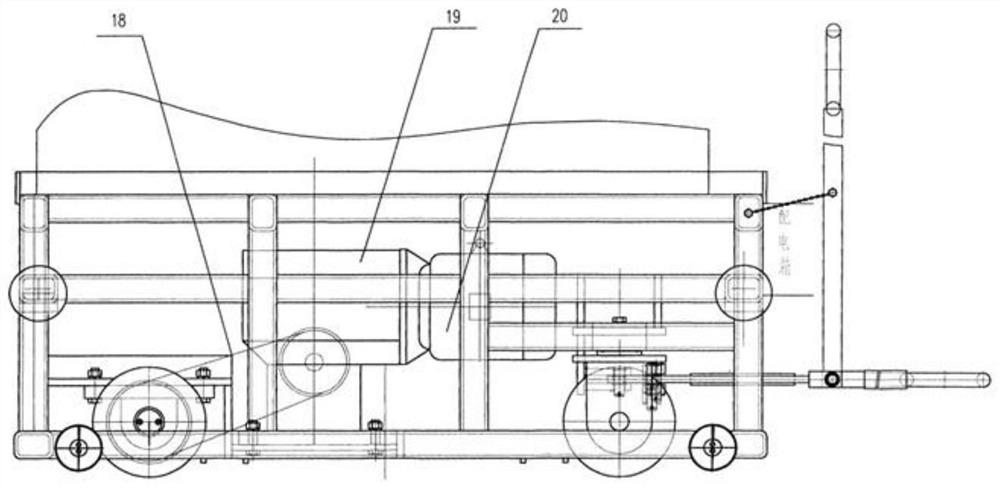

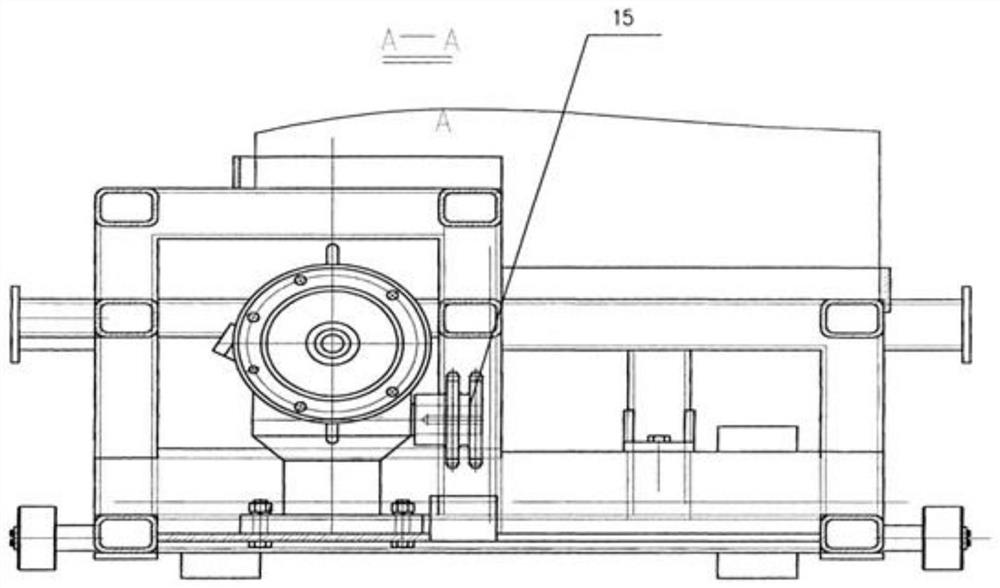

[0025] Below in conjunction with accompanying drawing and implementation situation this device is further described:

[0026] The heavy water reactor nuclear power plant described in the utility model is a device for transferring and hoisting heavy equipment, which is safe and reliable, easy to use, strong in stability, greatly reduces maintenance manpower, shortens maintenance and transfer time, and reduces collective and individual doses of personnel.

[0027] Such as Figure 4 Shown, this device is a driving trolley with a stepped platform, and its device vehicle frame 1 is a platform with steps on the top, which conforms to the bottom of the drive unit for storing the drive unit. This device is driven by the power supply, and advances are arranged on the operating handle bar 16, retreats, and stops the switch. Slow motor 20 is equipped with at the bottom of the trolley, four carrying rubber wheels 6, two driving wheels, and two running wheels are arranged at the bottom. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap