Left-right asymmetry type tee pipe internal high pressure forming device

A technology of internal high-pressure forming and tee pipe, which is applied in the field of internal high-pressure forming of pipes, can solve problems such as insufficient feeding, failure of high-pressure expansion type, leakage of high-pressure liquid, etc., and achieve the effect of avoiding insufficient feeding and preventing shock cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

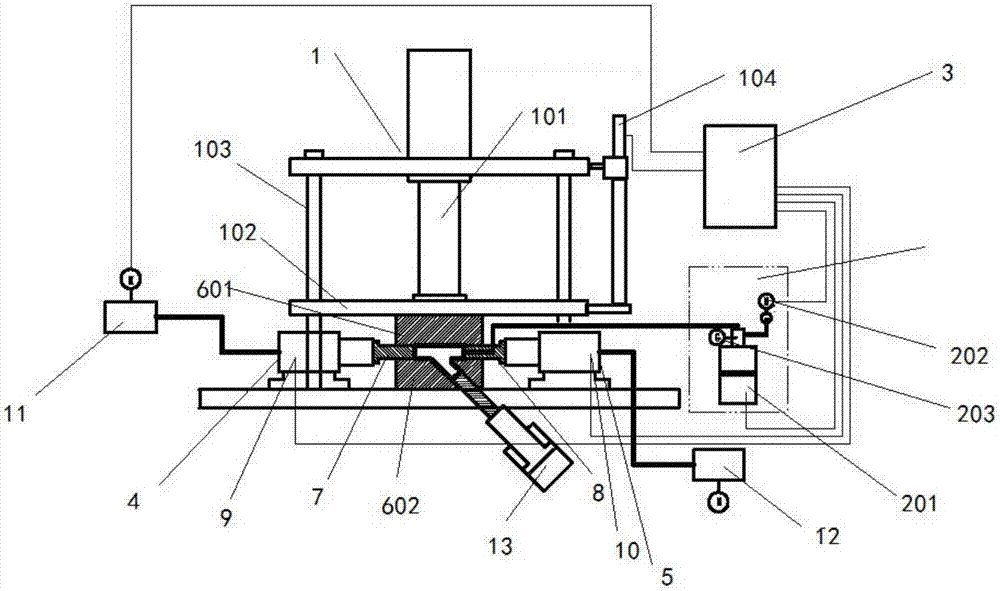

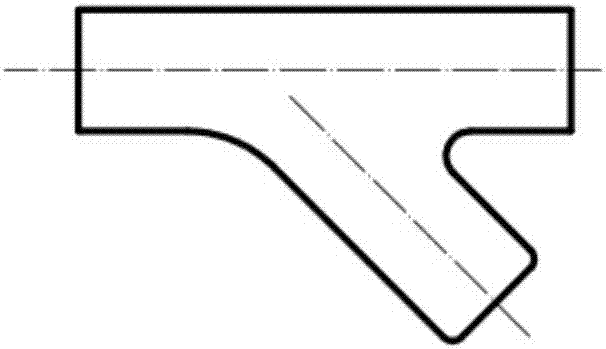

[0026] A left and right asymmetric tee pipe internal high pressure forming equipment, such as Figure 1-2 As shown, the internal high pressure forming equipment includes a clamping press (1), a booster system (2), an electrical control system (3), an upper mold (601), a lower mold (602), a left oil pump (11), Right oil pump (12), left push head (7), right push head (8) installed on the workbench, left thrust cylinder (4), right thrust cylinder (5), material support cylinder (13); wherein, the upper The mold (601) is installed on the movable beam (102) of the clamping press and is connected with the main cylinder (101) of the press through the movable beam (102) and the guide column (103). The cylinders are connected, the guide column (103) is connected with the beam displacement transmission (104), the left and right thrust cylinders are respectively connected with the left cylinder hydraulic pressure sensor (9), the right cylinder hydraulic pressure sensor (10), the booster s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com