Suction pressure type hydropower station

A technology for hydropower stations and water suction pipes, which is applied in the directions of hydropower generation, engine components, machines/engines, etc., to achieve the effect of large power generation and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

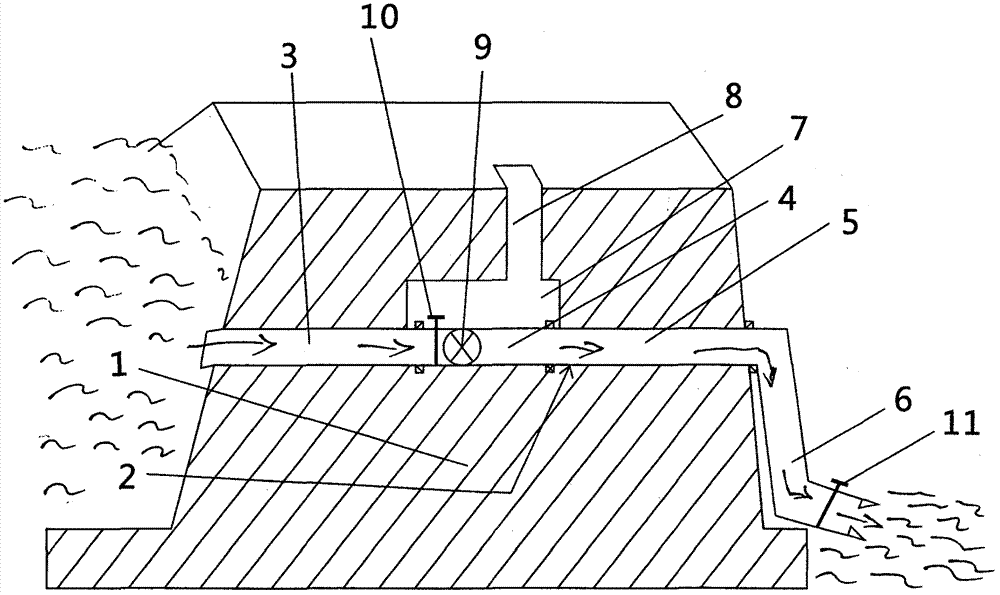

[0063] Example: Suction-pressure type external downstream pipeline hydropower station

[0064] Such as figure 1 : Pressure-suction type external down-pipeline hydropower station, the structure is a concrete structure dam body (1), the dam body (1) is provided with water delivery channels (2) through both sides of the dam body, and the water delivery channels (2) are divided into water in turn Section (3), installed section (4), outlet section (5) and external downstream outlet section (6) are provided with valves (11) at the outlets, and installed section (4) in the water delivery channel (2) in the dam body (1) ) Is provided with a machine room (7) and a machine room passage (8), and the installation section (4) is provided with a valve (10) and a turbine of the generator set (9).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com