A time-delayed dead-end shotgun and shotgun

A technology without dead ends and shotguns, applied in the directions of warheads, ammunition, weapon accessories, etc., can solve the problem of inability to strike at medium and long-range targets, and achieve the effect of improving safety and avoiding potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

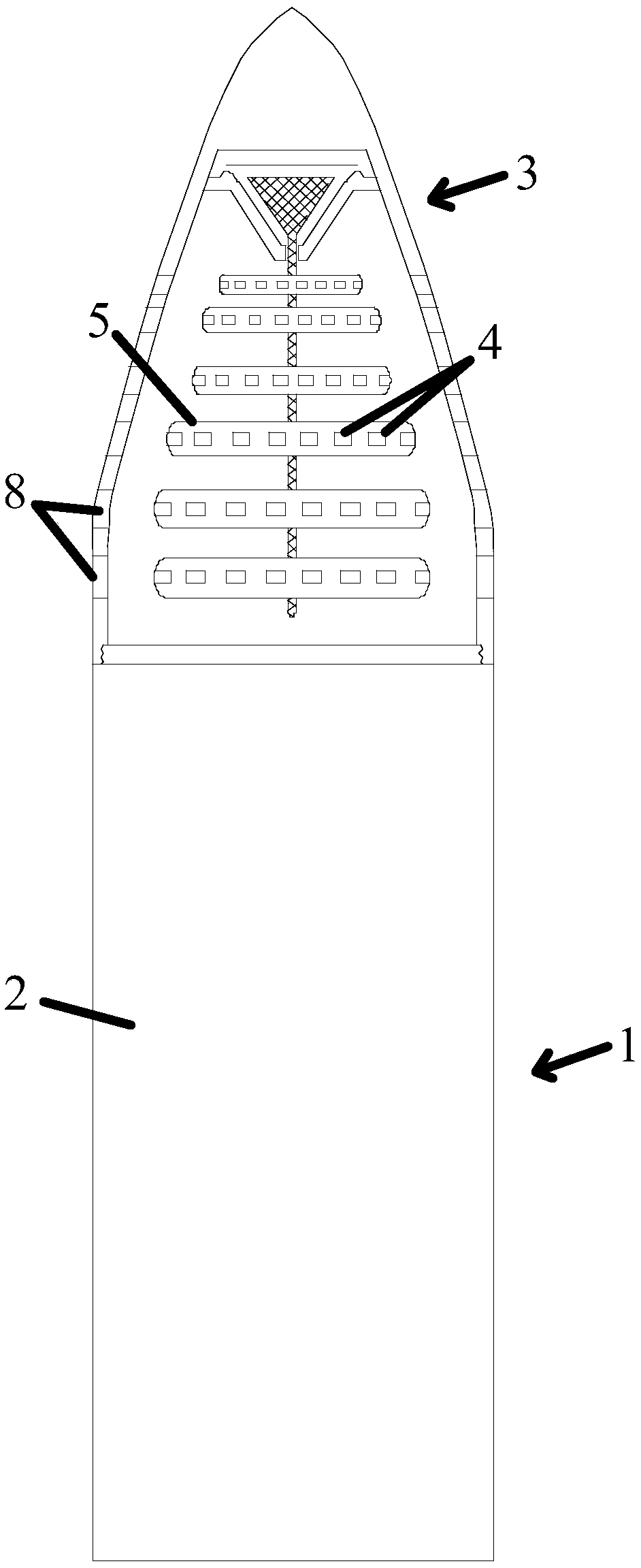

[0037] Such as figure 1 and figure 2 Delayed detonation no-dead shotguns shown, including:

[0038] The shotgun body 1 is provided with a primary motive medium 2 in the cavity of the shotgun body 1;

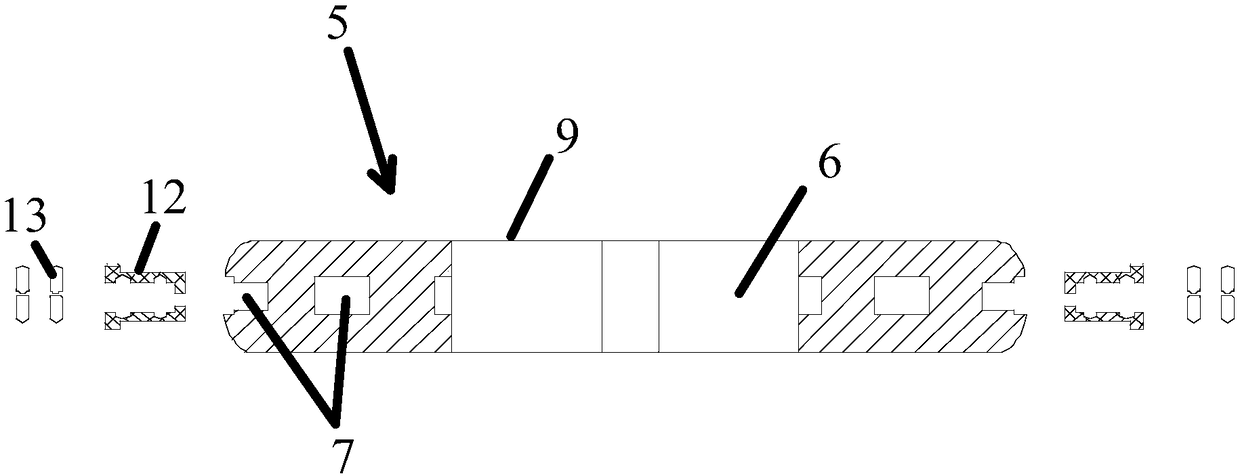

[0039] The shotgun 3 is arranged on the front end of the shotgun body 1. At least one body chamber 5 containing several bullets 4 is arranged in the inner cavity of the shotgun 3. The body chamber 5 is provided with a secondary power for exciting the bullets 4. medium 6 and an excitation structure for receiving excitation control instructions to excite the secondary motive medium 6;

[0040] The casing of the projectile chamber 5 is provided with a number of first firing holes 7 for guiding the firing direction of the bullet 4, and the casing of the shotgun 3 is provided with a number of first firing holes 7 correspondingly arranged for the bullet 4 to fly out. Two emission holes 8, a plurality of first emission holes 7 and a plurality of second emission holes 8 are arranged ...

Embodiment 2

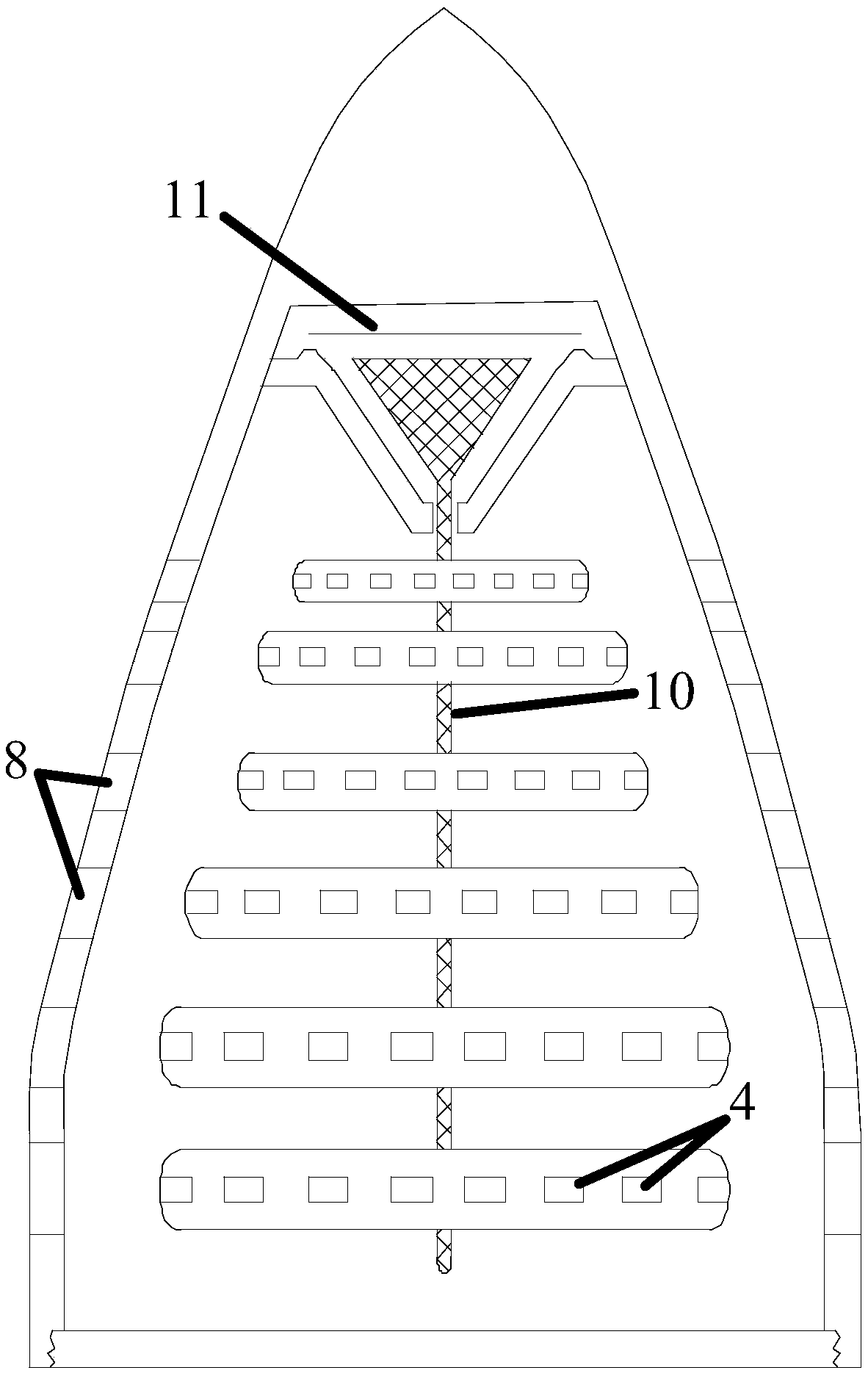

[0050] Such as figure 1 and figure 2 Delayed detonation no-dead shotguns shown, including:

[0051] The shotgun body 1 is provided with a primary motive medium 2 in the cavity of the shotgun body 1;

[0052] The shotgun 3 is arranged on the front end of the shotgun body 1. At least one body chamber 5 containing several bullets 4 is arranged in the inner cavity of the shotgun 3. The body chamber 5 is provided with a secondary power for exciting the bullets 4. medium 6 and an excitation structure for receiving excitation control instructions to excite the secondary motive medium 6;

[0053] The casing of the projectile chamber 5 is provided with a number of first firing holes 7 for guiding the firing direction of the bullet 4, and the casing of the shotgun 3 is provided with a number of first firing holes 7 correspondingly arranged for the bullet 4 to fly out. Two emission holes 8, a plurality of first emission holes 7 and a plurality of second emission holes 8 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com