New energy vehicle electrical connector with integrally and front installed cable seal ring and protective sleeve

A new energy vehicle, cable sealing technology, applied in the electrical field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

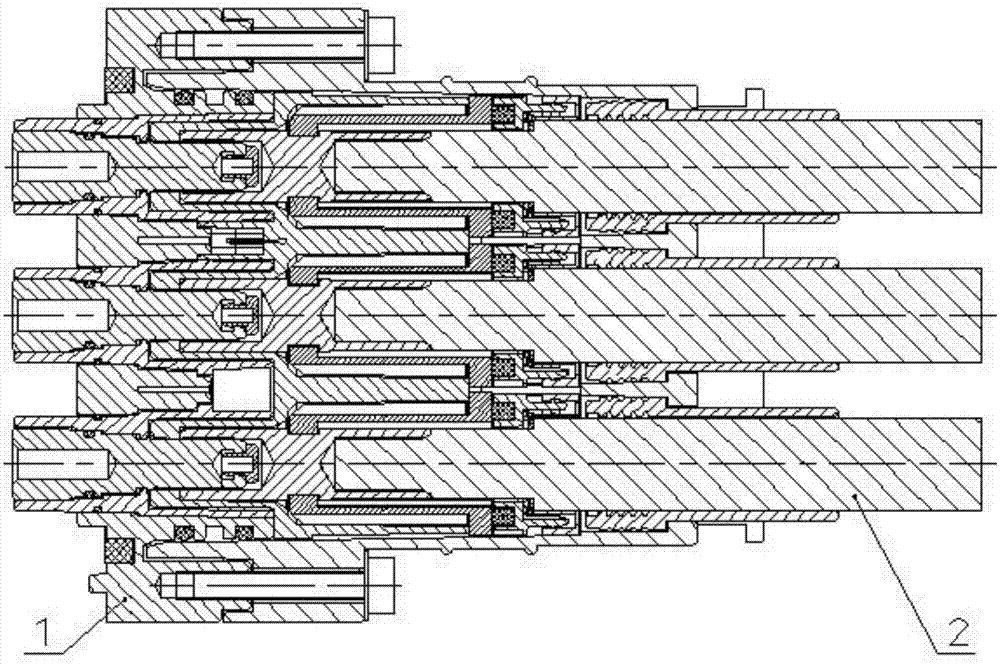

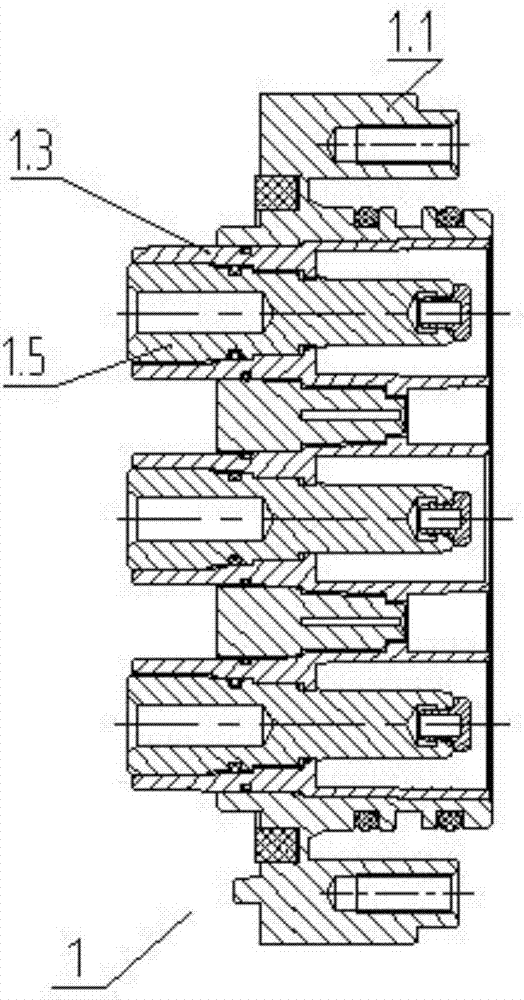

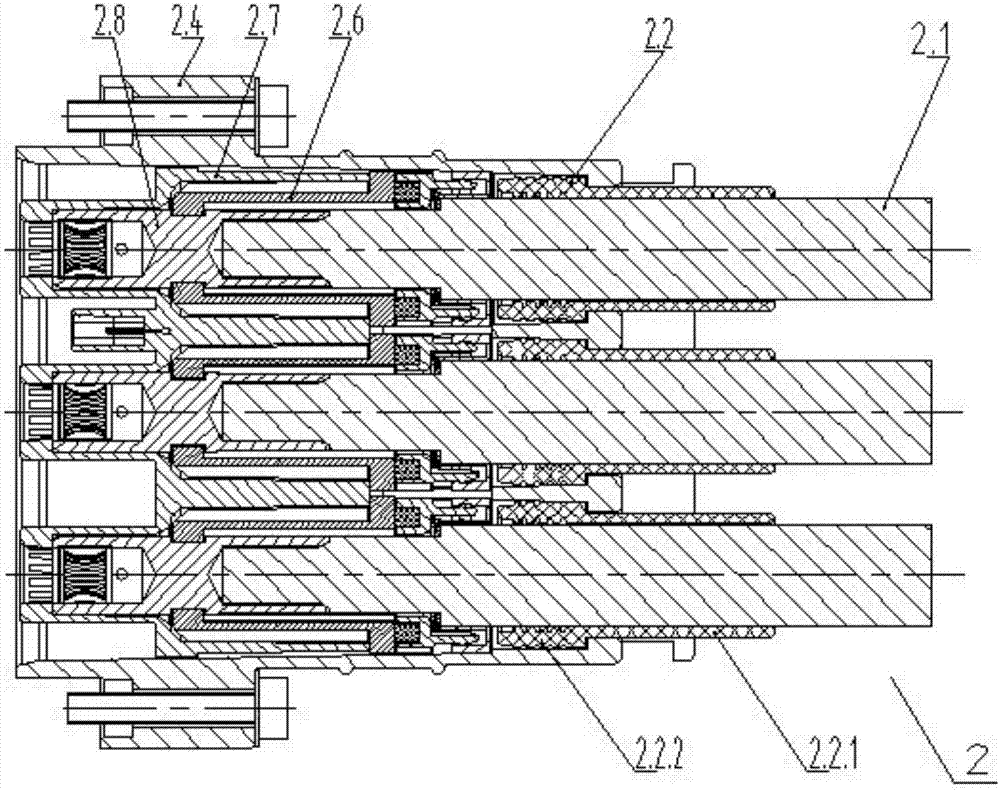

[0022] As shown in the attached figure, the new energy vehicle electrical connector with the cable sealing ring and the protective cover integrated in the front, including the board end 1 and the wire end 2; the board end 1 includes the board end shell 1.1, the board end inner core 1.3, and the board end male terminal 1.5; board end inner core 1.3 is inserted into the inner hole of board end shell 1.1; board end male terminal 1.5 is inserted into the inner hole of board end inner core 1.3; wire end 2 includes cable 2.1, cable sealing ring 2.2, wire end Shell 2.4, terminal jacket 2.6, wire end inner core 2.7, wire end female terminal 2.8; wire end female terminal 2.8 is inserted into the inner hole of wire end inner core 2.7 from the rear end of wire end inner core 2.7; terminal jacket 2.6 is a sleeve The front end of the terminal jacket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com