One-way separation type extensible interconnection mother board

A separate, unidirectional technology, applied in the direction of electrical connection of printed components, structural connection of printed circuits, contact parts, etc., can solve the problems that circuit modules cannot be drawn out arbitrarily, cannot be expanded, and achieve rich types and forms, convenient and fast Clutch, increase the effect of expanding space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

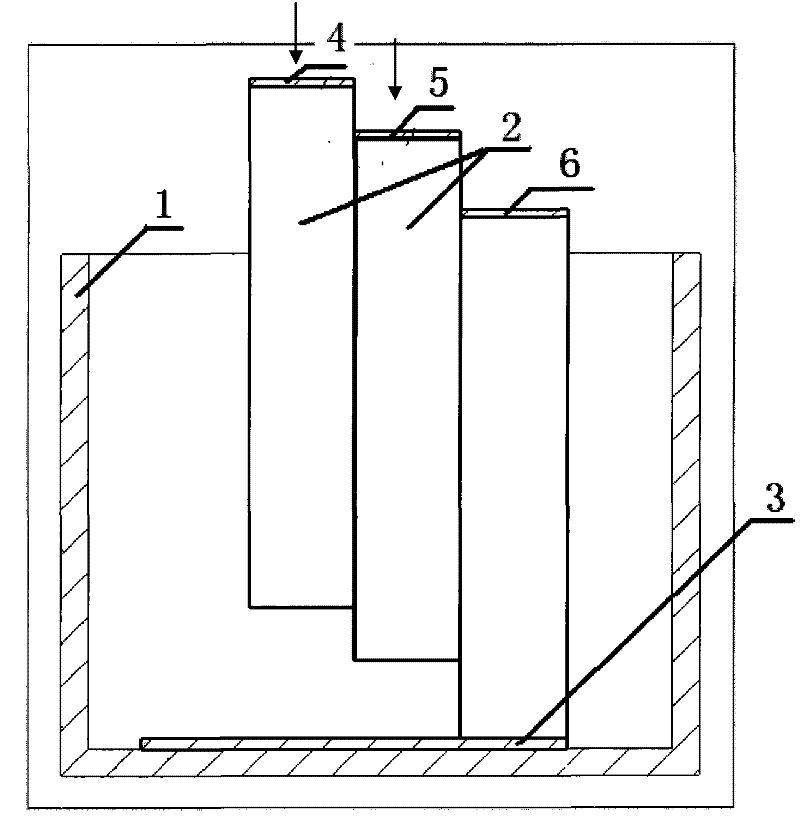

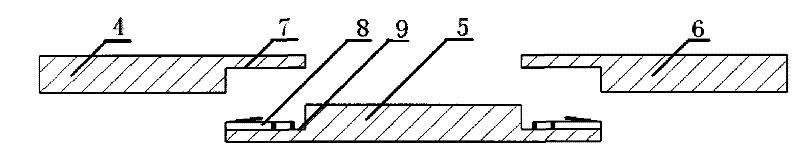

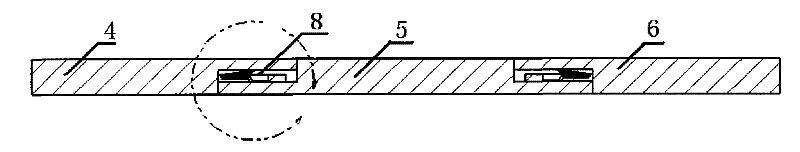

[0019] refer to Figure 1 to Figure 7 . The present invention will be described step by step below in conjunction with the accompanying drawings and examples. In the following drawings and implementations, the circuit module 2 still uses figure 1 As shown, in the chassis 1 , a conventional motherboard 3 is used below to interconnect the circuit modules. When the total amount of signal line core wires exceeds the specified amount of the plug-in channel / port core number of the printed circuit board unit circuit module or the number of circuit modules accommodated, it is used above the circuit module 2, and the present invention is interconnected by at least one PCB rigid printed board. The main interconnection motherboard 5 and two unidirectionally separated expandable interconnection motherboards composed of PCB rigid printed board sub-interconnection motherboards 4 and 6 interconnect the circuit module 2 to facilitate the arbitrary insertion and removal of the circuit module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com