Secondary utilization method of dicing knife

A dicing and blade technology, which is applied in the field of secondary utilization of dicing knives, can solve problems such as high cost, increased production cost, waste of resources, etc., and achieve the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

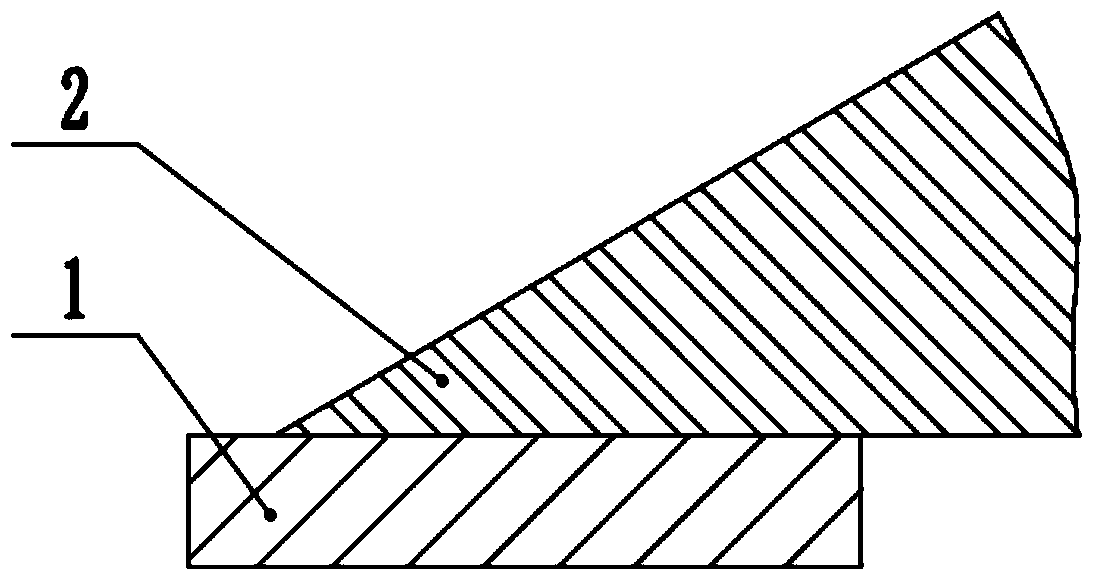

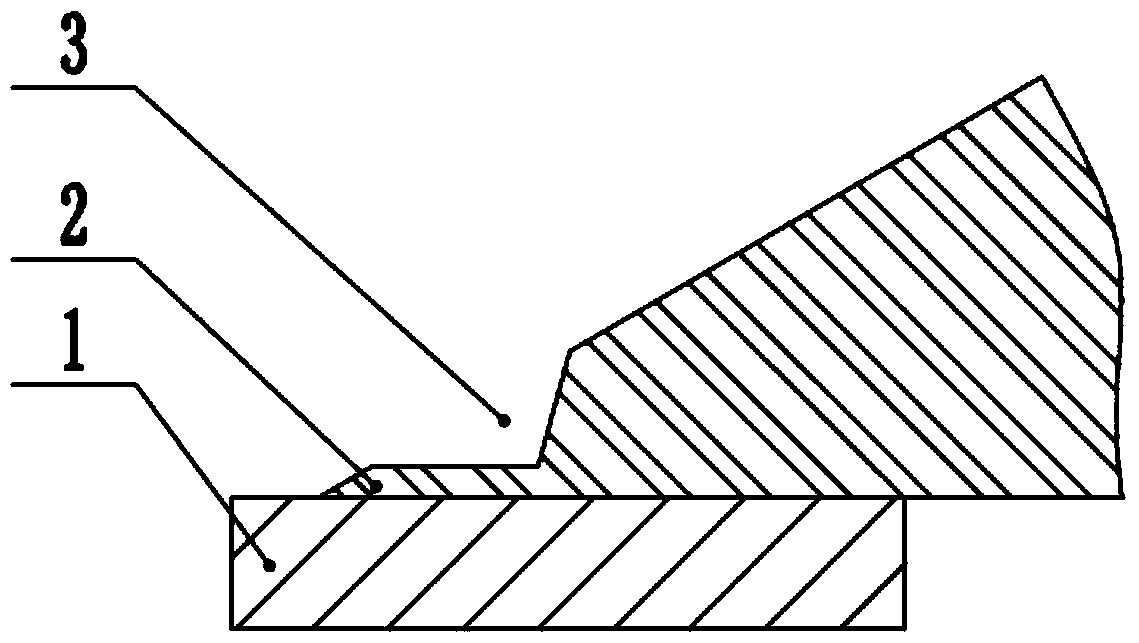

[0023] The invention is a method for secondary utilization of a dicing knife. In this embodiment, it is aimed at the old scribing blade that has been used, and the protrusion of the old scribing blade is not enough to meet the minimum requirements for processing, such as figure 2 As shown, it includes a blade 1 and a cutter hub 2 that fixes the blade 1, the cutter hub 2 is made of aluminum, and the blade 1 is made of diamond micropowder. The position where blade 1 exposes cutter hub 2 is a blade, and the length (ie blade extension) that blade stretches out from cutter hub 2 is less than a specified value, so it can no longer be used directly.

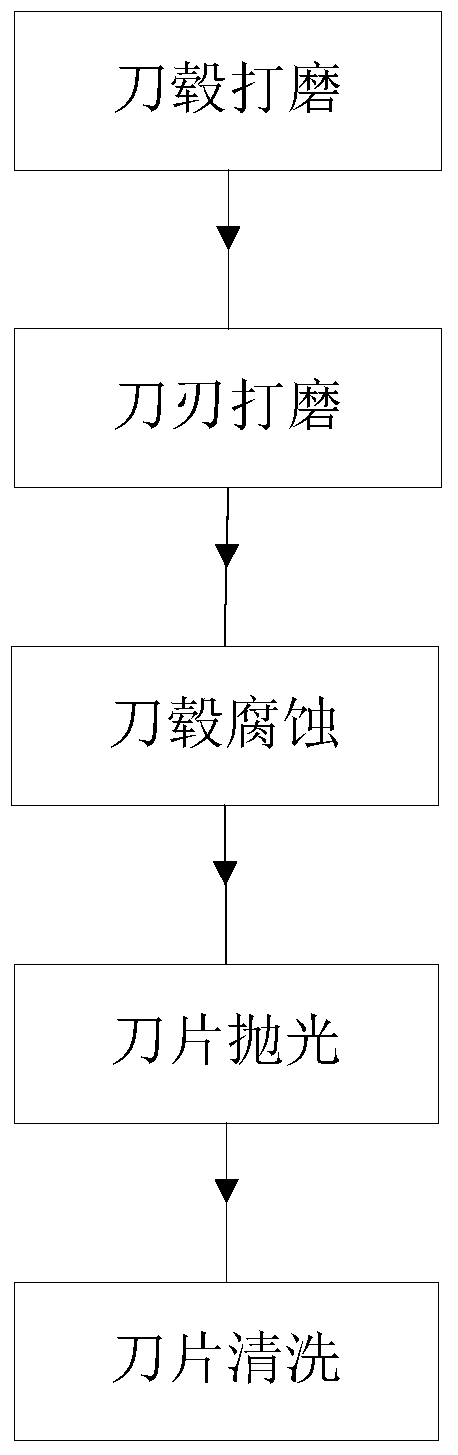

[0024] see figure 1 , the method for secondary utilization of the above-mentioned sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com