A foam concrete curing device

A technology of foam concrete and geomembrane, which is applied in roads, construction materials processing, construction, etc., can solve the problems of drying shrinkage cracks, insufficient hydration of cement particles, and inability to transform crystallization, etc., and achieve the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

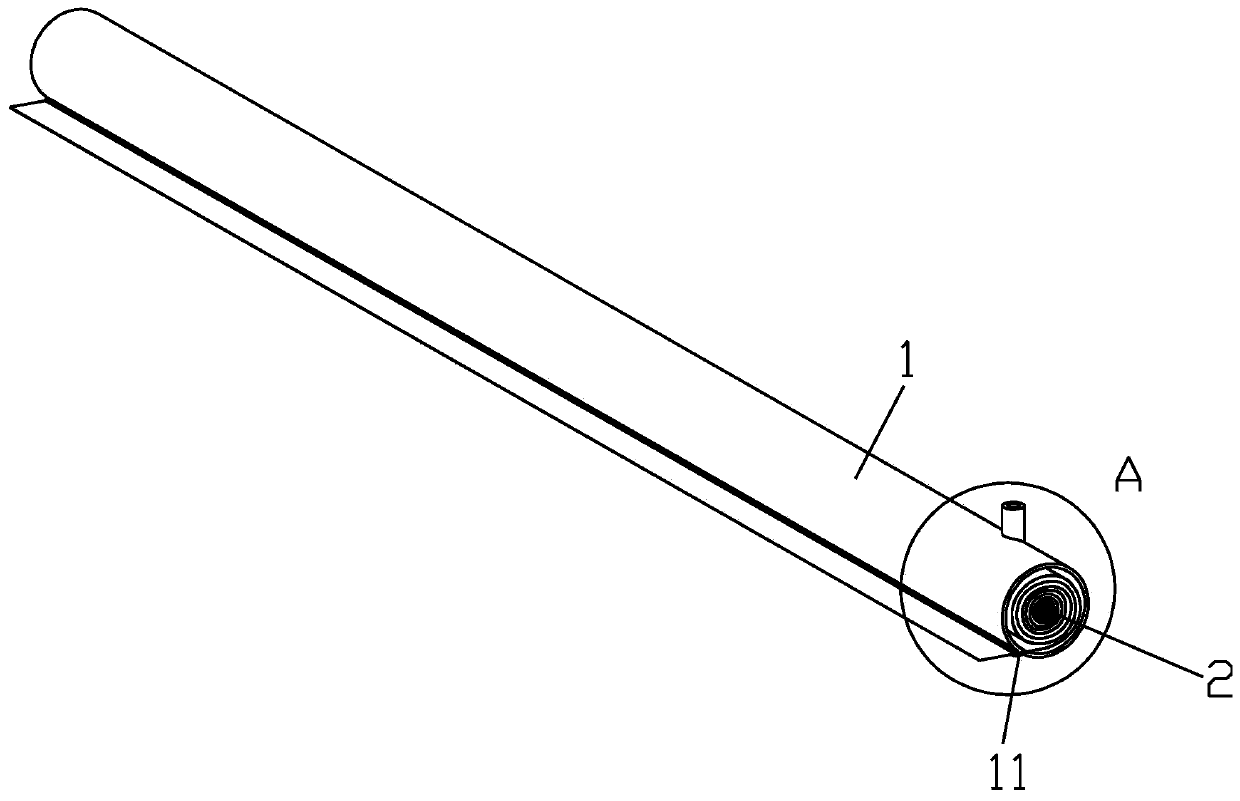

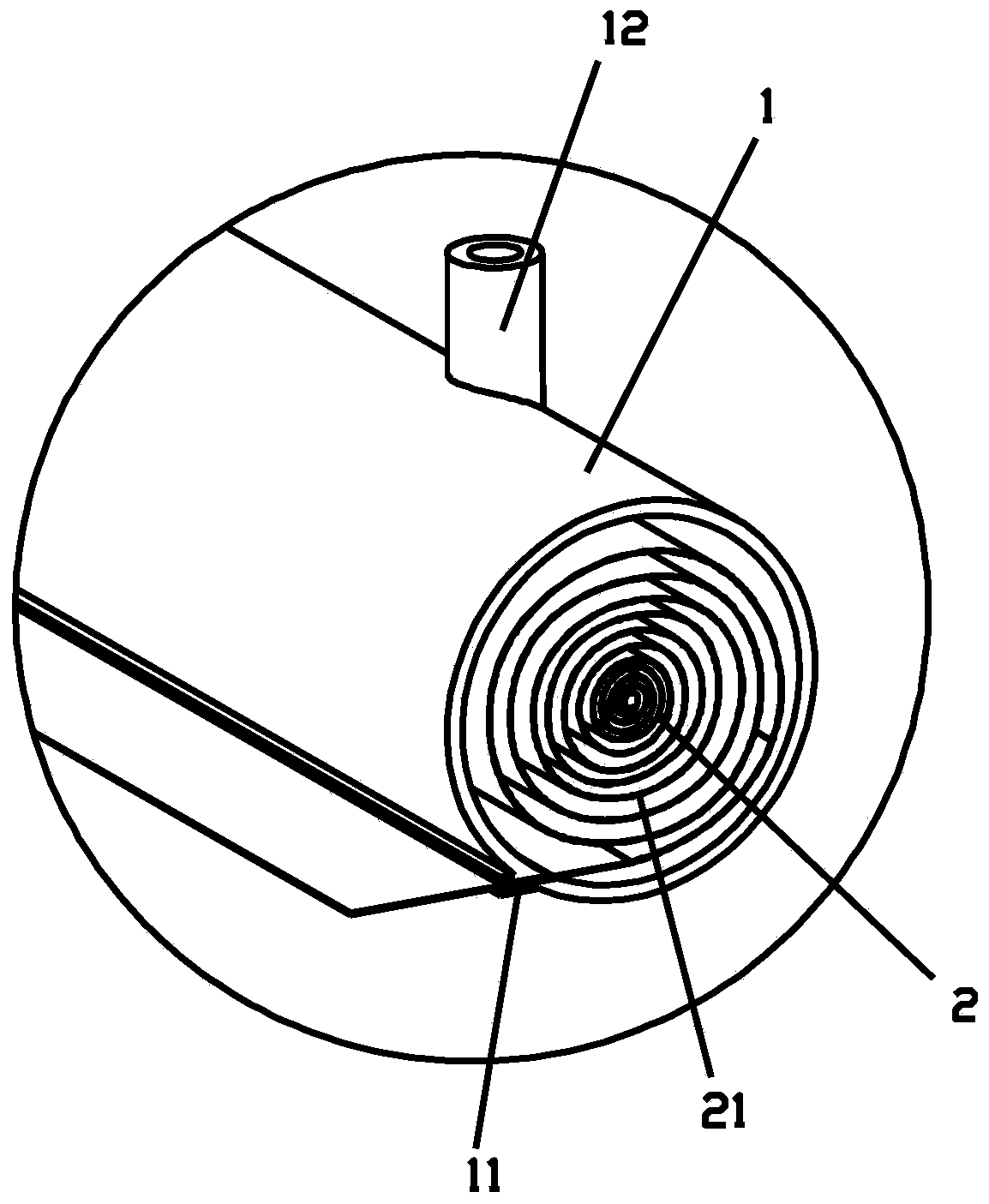

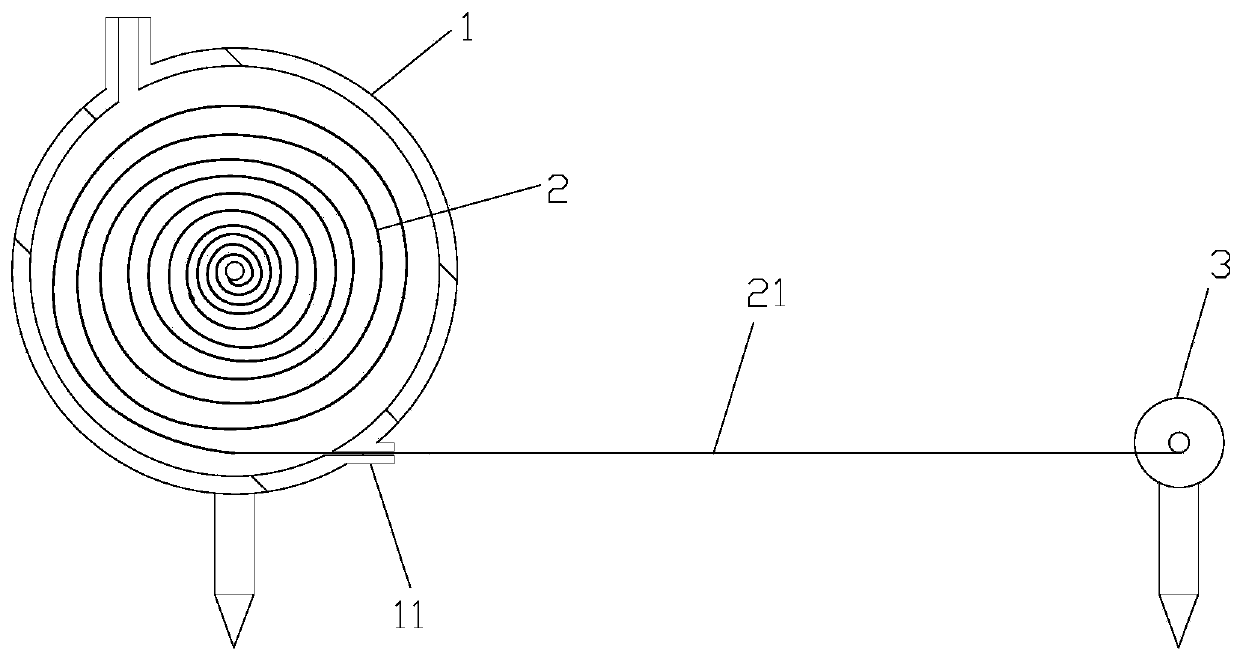

[0039] Such as Figure 1~4 As shown, a foam concrete curing device includes: a container 1; a geomembrane elastic roll 2 located in the container 1, which is used to provide a geomembrane 21 covering the foam concrete; a geomembrane is provided below the middle of the container 1 The open end 11 drawn from one end of 21; the positioning rod 3 is used to fix one end of the geomembrane 21 drawn from the container 1, so that the drawn geomembrane covers the surface of the foam concrete.

[0040] In the present invention, by arranging the geomembrane 21 in the container 1, the geomembrane 21 that does not participate in maintenance can be stored for secondary use. During use, the container 1 can be fixed first, and positioned by translation The rod 3 allows the geomembrane 21 to be pulled out from the container 1 to cover the surface of the foamed concrete. The water-proof property of the geomembrane 21 can prevent the moisture in the foamed concrete from volatilizing into the spa...

Embodiment 2

[0048] In the above-mentioned embodiments, the one-time water supply method is mainly used in the technical direction of increasing the humidity of the geomembrane 21 , that is, the curing method of the foamed concrete is optimized by the water taken out from the container 1 at one time.

[0049] In this embodiment, different from the first embodiment, it is intended to provide the geomembrane 21 with a continuous water supply for a required period of time in a full cycle. Specifically, such as Figure 5~7 As shown, separation structures 4 for supporting the two layers in the geomembrane 21 are arranged on the inner wall of the container 1 on both sides of the gap height direction of the opening end 11. In this embodiment, it is also necessary to reduce the opening end as much as possible. The gap height of 11, the separation structure 4 is used to separate the two layers of geomembrane 21 and support and guide the two layers, and the two layers of geomembrane 21 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com