A Fatigue Test Method for Railway Freight Car Bogies

A fatigue test, railway wagon technology, applied in the field of machinery, can solve problems such as fracture, irregular wear, and vehicle dynamic performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

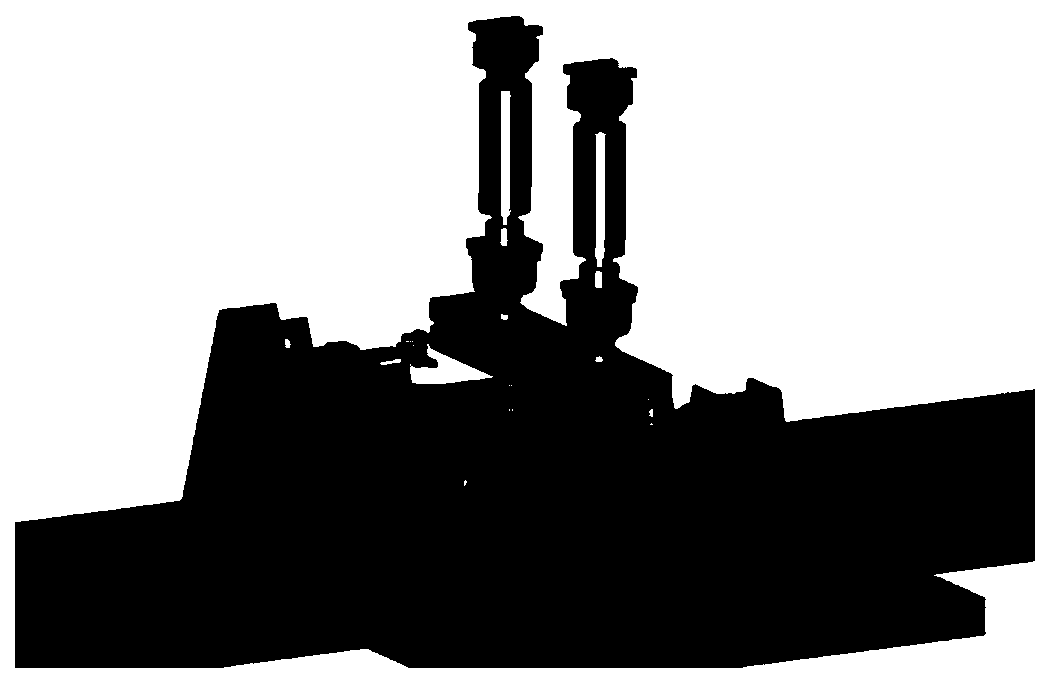

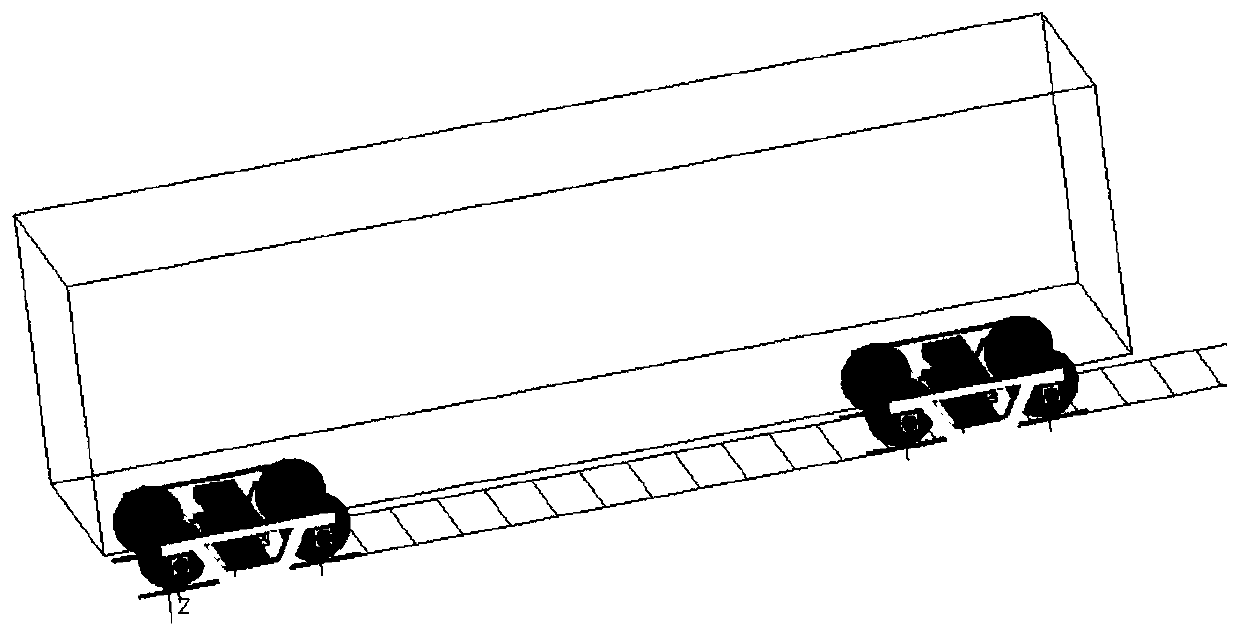

[0063] The test bench simulates the loading beam to act on the bogie core plate and side bearing to simulate the vertical load, lateral load and torsional load of the bogie.

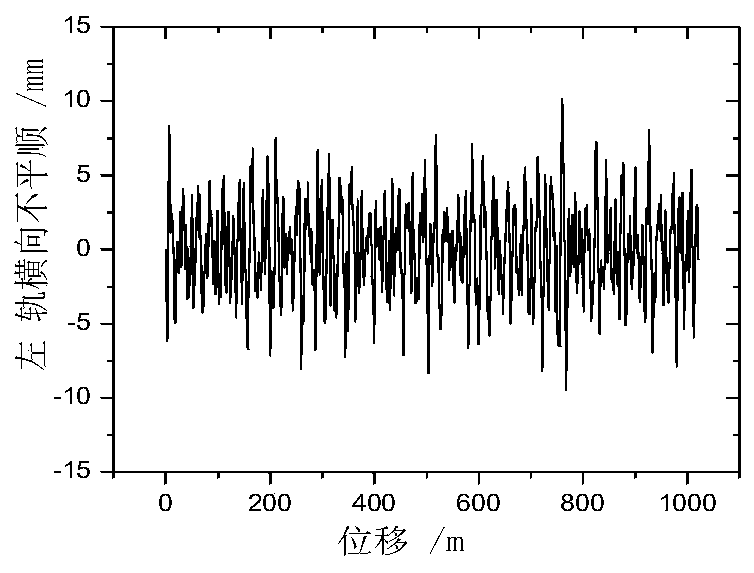

[0064] Use SIMPACK multi-body dynamics software

[0065] 1. Establish a dynamic model of the tested bogie and a typical car body,

[0066] The railway vehicle is a complex multi-body system, which not only has the interaction force and relative movement between the components, but also the relationship between the wheel and the rail. Therefore, the theoretical calculation and analysis model can only make corresponding assumptions or simplifications for some minor factors according to the main purpose and requirements of the research, and make simulations that conform to the actual situation as much as possible on the major factors that have a greater impact on the dynamic performance. . According to the structural characteristics of the bogie, when establishing the dynamic model, the following assumptions are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com