Processing device for electric cooker cover

A technology for processing equipment and rice cookers, applied in metal processing equipment, safety equipment, forming tools, etc., can solve the problems of material waste, time-consuming and labor-intensive, and increased mechanical loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

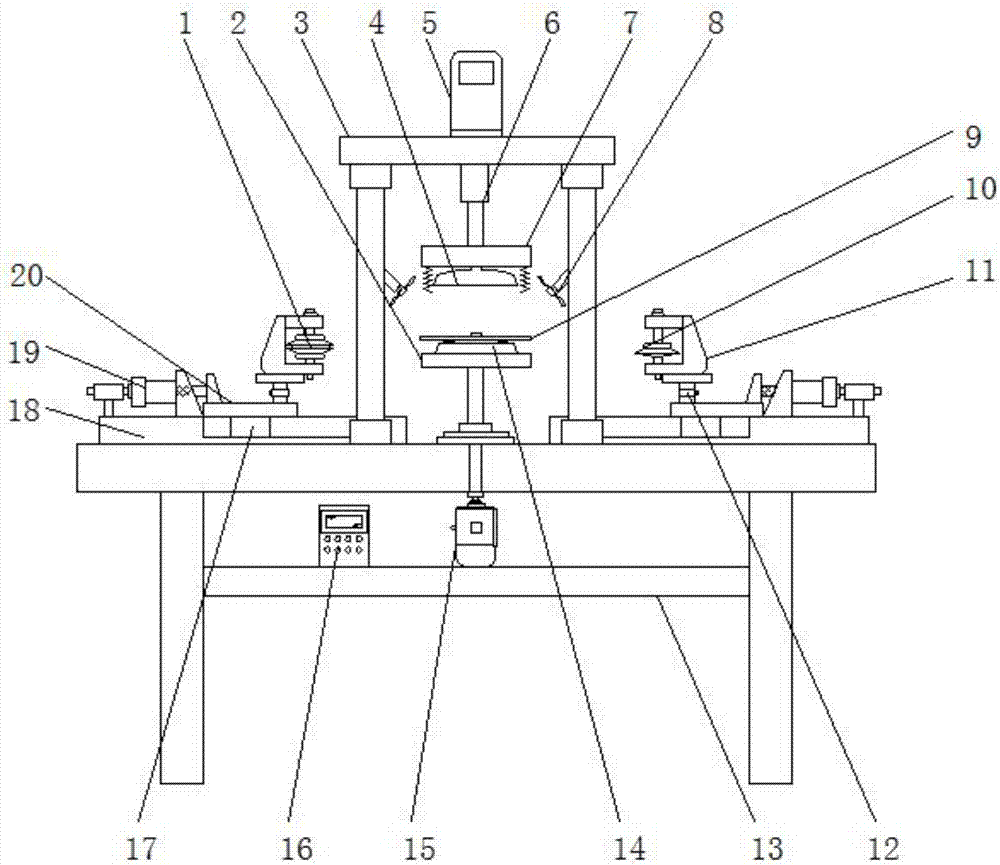

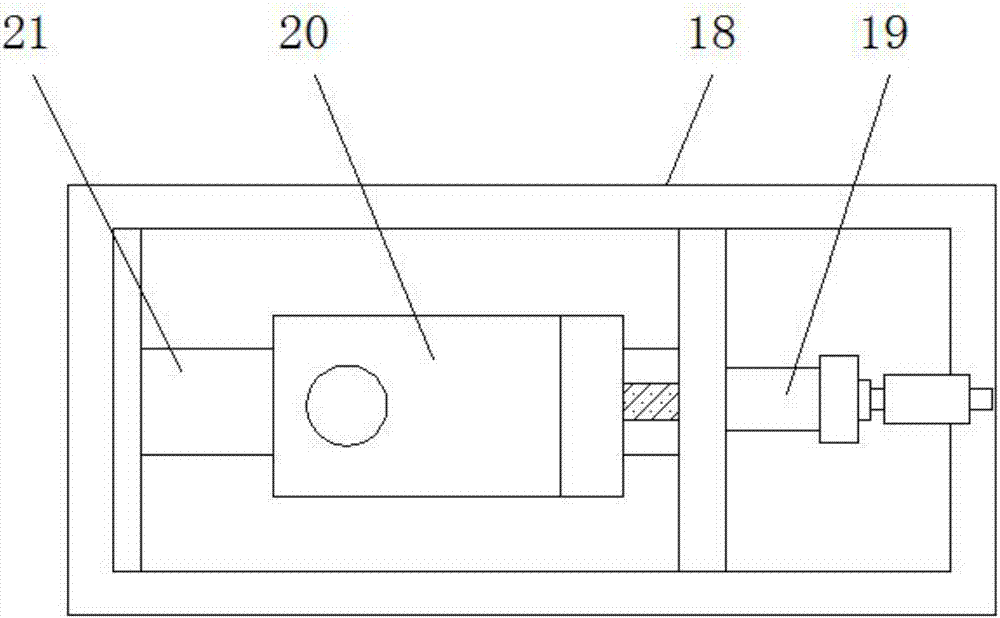

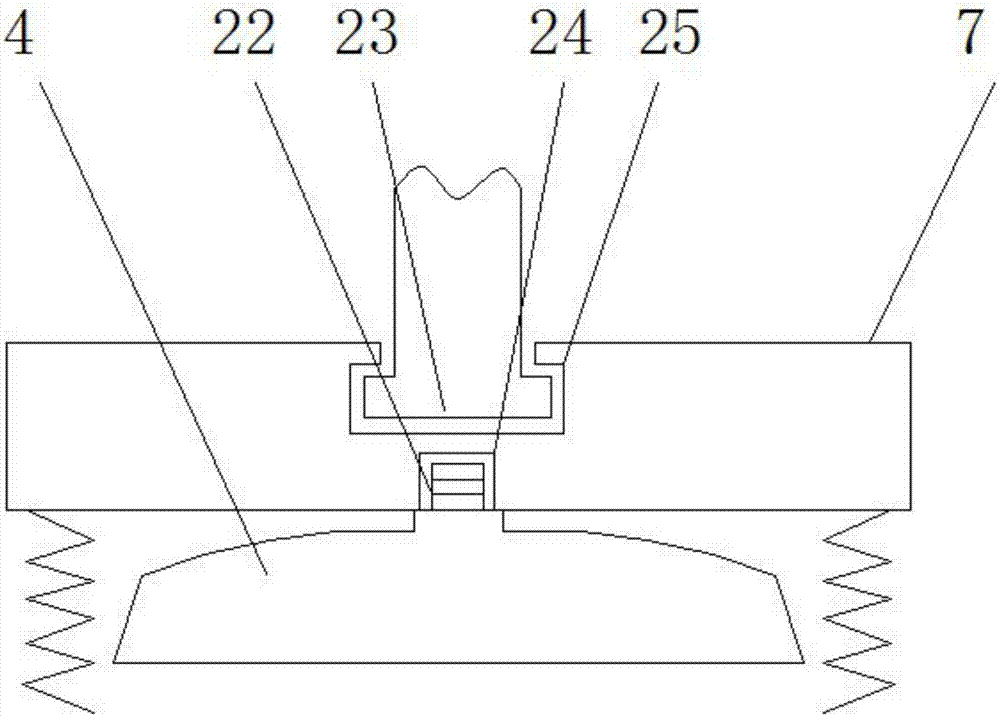

[0021] Such as Figure 1 to Figure 6 Shown, a kind of electric cooker pot lid processing equipment comprises lower mold fixed plate 2, first frame body 3, upper mold fixed plate 7 and second frame body 13, and the middle position of second frame body 13 tops is fixed with first Frame body 3, and a hydraulic cylinder 5 is installed at the middle position of the top of the first frame body 3, the bottom end of the hydraulic cylinder 5 is fixed with a first hydraulic telescopic rod 6, and a connecting block is installed at the bottom end of the first hydraulic telescopic rod 6 23. The upper mold fixing plate 7 is installed on the bottom end of the first hydraulic expansion rod 6, and the top of the upper mold fixing plate 7 is provided with a rotat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap