Conical mixing container with digital display function

A mixing container and conical technology, which is applied in the field of conical mixing containers, can solve the problems of co-existence of multiple flow and mixing forms of powder, and achieve the effects of convenient measurement, improved equipment functions, and improved dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

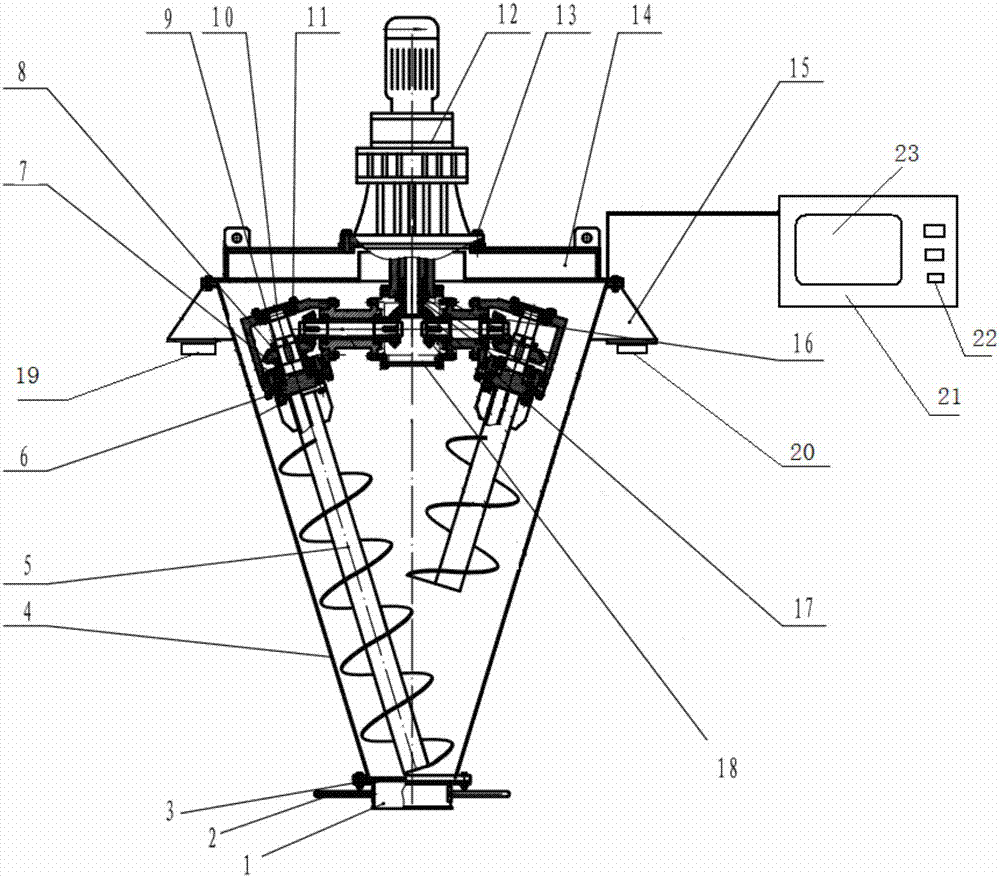

[0017] The invention provides a conical mixing container with digital display function, which is characterized in that: the conical mixing container with digital display function includes a plum switch, a wrench, a discharge port flange, a cone, Stirring shaft, drive shaft, roller bearing, first gear, deep groove ball bearing, bearing gland, hex head bolt, reducer, hex head bolt, upper cover, support, second gear, reducer output gear , sealing gland;

[0018] Among them: the discharge port flange is arranged at the lower part of the cone cylinder, and the bottom of the discharge port flange is equipped with a plum switch and a wrench; a stirring shaft is installed inside the cone cylinder, the stirring shaft is connected with the transmission shaft, and the transmission shaft is installed on the transmission shaft through roller bearings. on the frame; a first gear is installed on the transmission shaft, the first gear cooperates with the second gear for transmission, and the ...

Embodiment 2

[0025] The invention provides a conical mixing container with digital display function, which is characterized in that: the conical mixing container with digital display function includes a plum switch, a wrench, a discharge port flange, a cone, Stirring shaft, drive shaft, roller bearing, first gear, deep groove ball bearing, bearing gland, hex head bolt, reducer, hex head bolt, upper cover, support, second gear, reducer output gear , sealing gland;

[0026] Among them: the discharge port flange is arranged at the lower part of the cone cylinder, and the bottom of the discharge port flange is equipped with a plum switch and a wrench; a stirring shaft is installed inside the cone cylinder, the stirring shaft is connected with the transmission shaft, and the transmission shaft is installed on the transmission shaft through roller bearings. on the frame; a first gear is installed on the transmission shaft, the first gear cooperates with the second gear for transmission, and the ...

Embodiment 3

[0032] The invention provides a conical mixing container with digital display function, which is characterized in that: the conical mixing container with digital display function includes a plum switch, a wrench, a discharge port flange, a cone, Stirring shaft, drive shaft, roller bearing, first gear, deep groove ball bearing, bearing gland, hex head bolt, reducer, hex head bolt, upper cover, support, second gear, reducer output gear , sealing gland;

[0033] Among them: the discharge port flange is arranged at the lower part of the cone cylinder, and the bottom of the discharge port flange is equipped with a plum switch and a wrench; a stirring shaft is installed inside the cone cylinder, the stirring shaft is connected with the transmission shaft, and the transmission shaft is installed on the transmission shaft through roller bearings. on the frame; a first gear is installed on the transmission shaft, the first gear cooperates with the second gear for transmission, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com