Forming device and forming method of ultra-thin cotton core for disposable sanitary products

A technology for sanitary products and molding devices, applied in medical science, absorbent pads, etc., can solve the problems of product weight deviation, uneven inner and outer thickness of cotton core, manufacturing difficulties, etc. Avoid wrinkling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

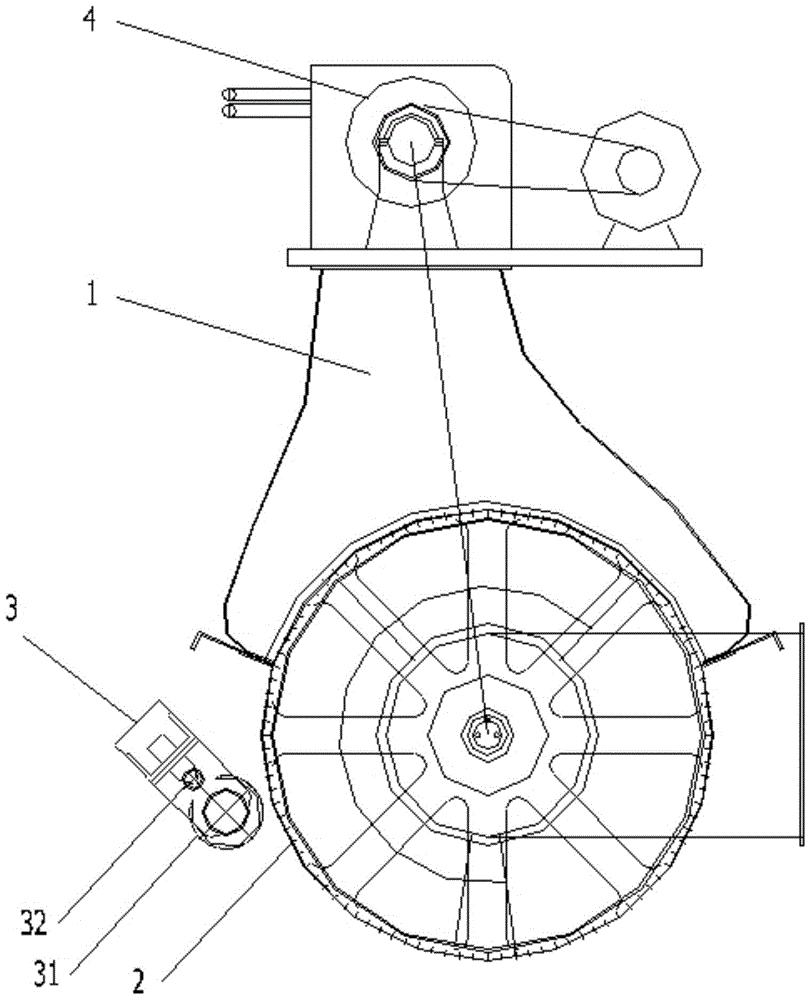

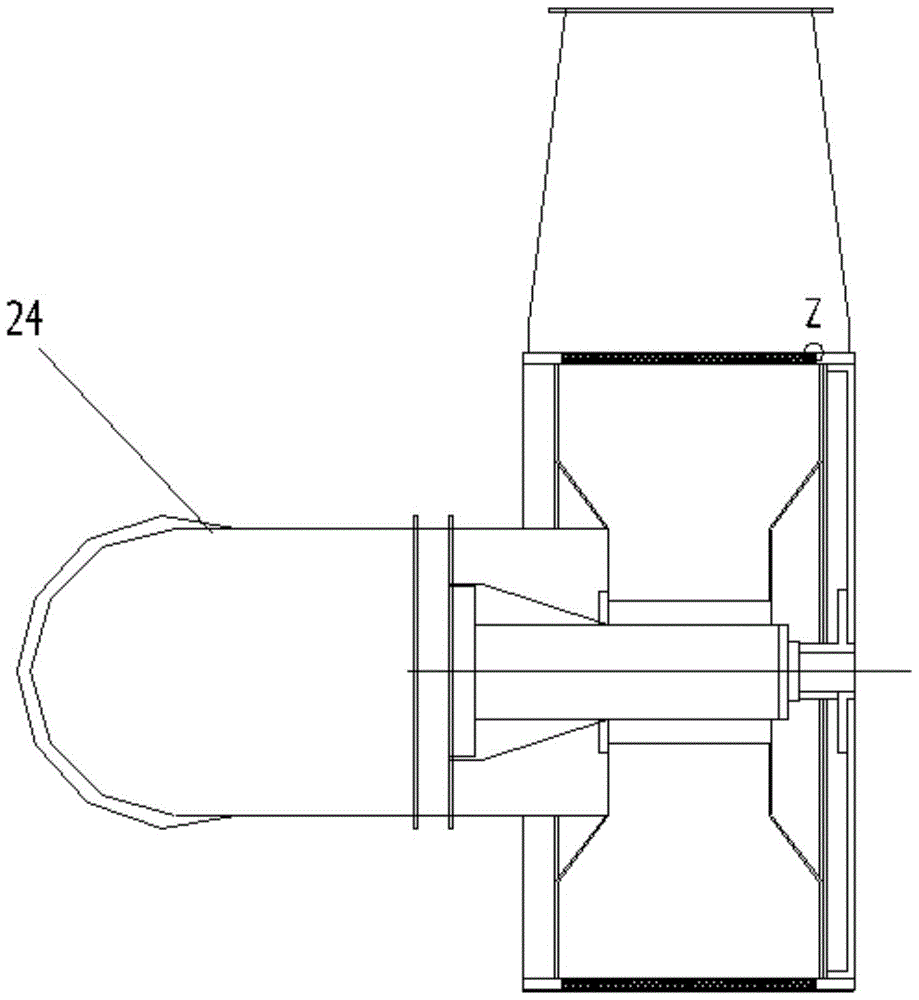

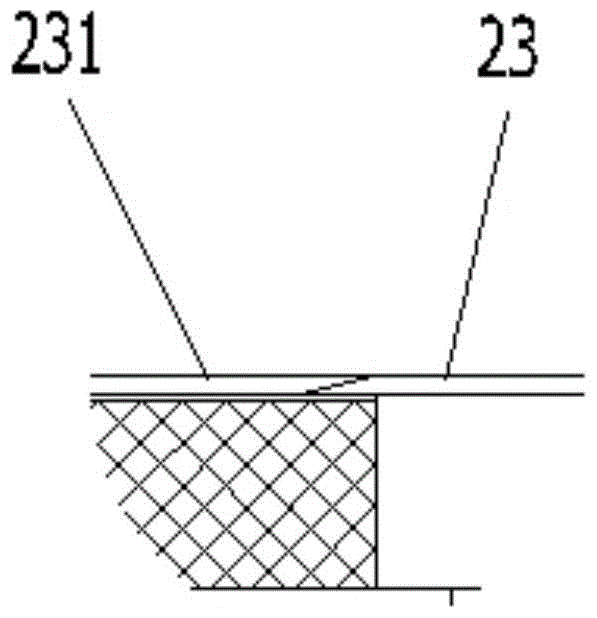

[0038] Such as figure 1 with figure 2 As shown, the molding device of the ultra-thin cotton core of the disposable hygiene product comprises a pulverizer 4, an output end 5, a cashmere collection bin 1 and a molding hub 2, and is characterized in that: the arc-shaped lower opening 12 of the cashmere collection bin 1 is designed as With respect to the left-right symmetrical structural design of the forming hub 2, the cashmere collection bin 1 has an upper opening 11 connected to the outlet of the pulverizer 4 and an arc-shaped lower opening 12 covering the outer circular surface of the molding hub 2. The left and right sides of the lower end are respectively provided with an opening 13 at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com