Improved tunnel waterproof and drainage hot-melt gasket and fixing construction method

A hot-melt gasket, an improved technology, used in tunnels, tunnel linings, earthwork drilling and mining, etc., to achieve the effects of avoiding water leakage, simple production, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

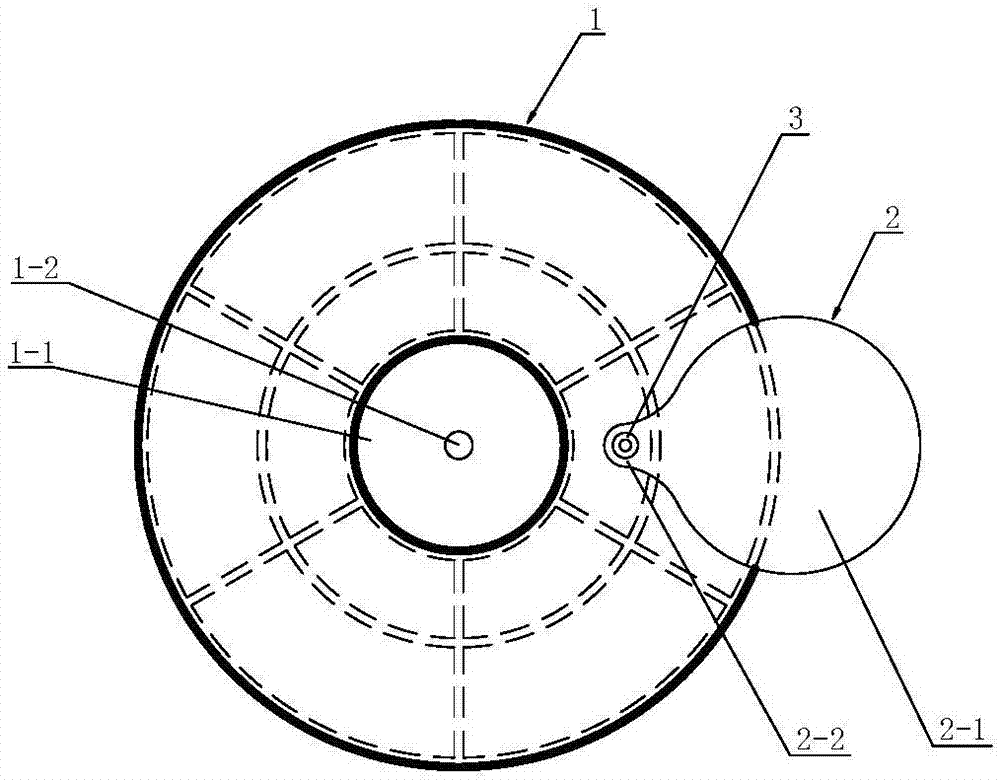

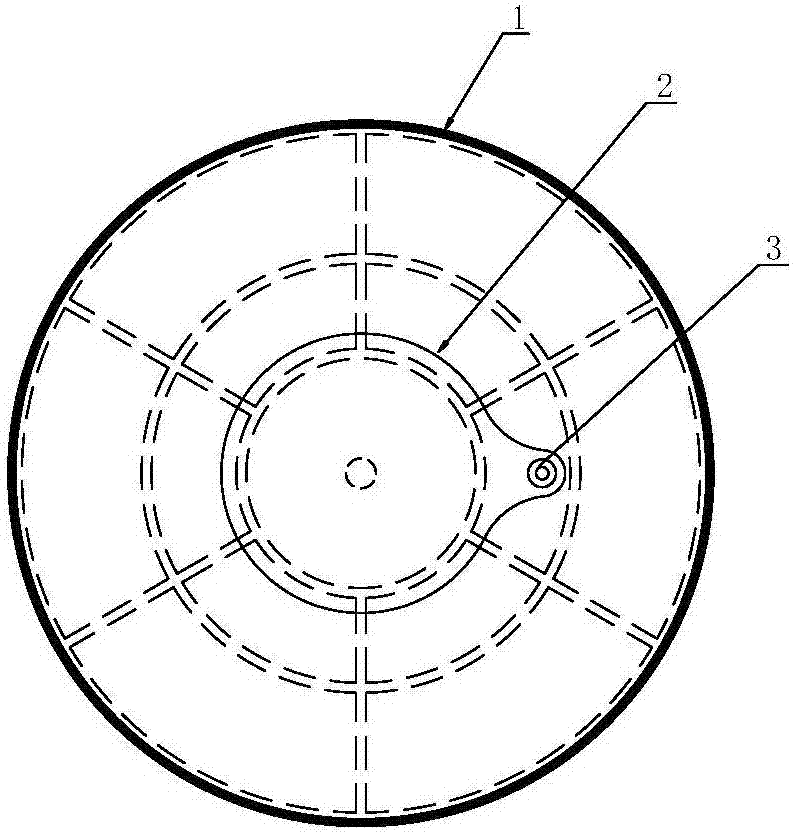

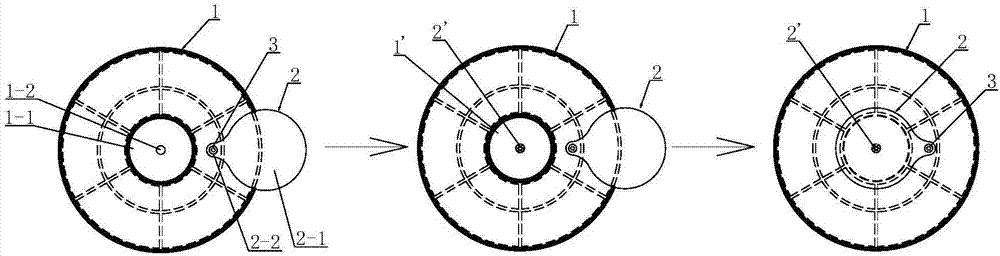

[0021] An improved tunnel waterproof hot-melt gasket, see attached figure 1 and 2 , including a hot-melt gasket body 1, a circular groove 1-1 and a central through hole 1-2 are arranged on the hot-melt gasket body, wherein the circular groove is used for metal gasket installation, and the central through hole is used for steel nails to penetrate overused.

[0022] The innovative point of this technical solution is: it also includes the puncture-proof pad 2 . The anti-puncture gasket is made of the same material as the hot-melt gasket body, and the anti-puncture gasket is a flat gasket structure, which is formed by the gasket body part 2-1 and the body of the hot-melt gasket. The outer connection part 2-2 is formed, and a connection hole is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com