Seedling pushing rod head structure device for overflowing farmland rice transplanter

A technology of a rice transplanter and a seedling pusher is applied in the field of the structure device of the pusher head of a rice transplanter in an over-flow farmland, which can solve the problems such as inability to adjust the structure, and achieve the effects of reducing the resistance of rice transplanting, reducing the floating rate and facilitating coverage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

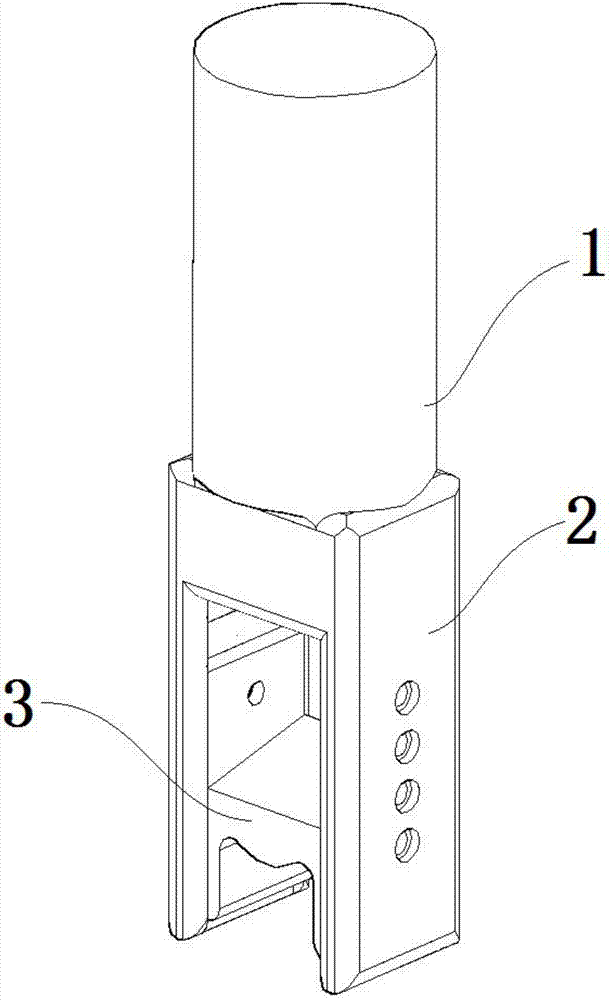

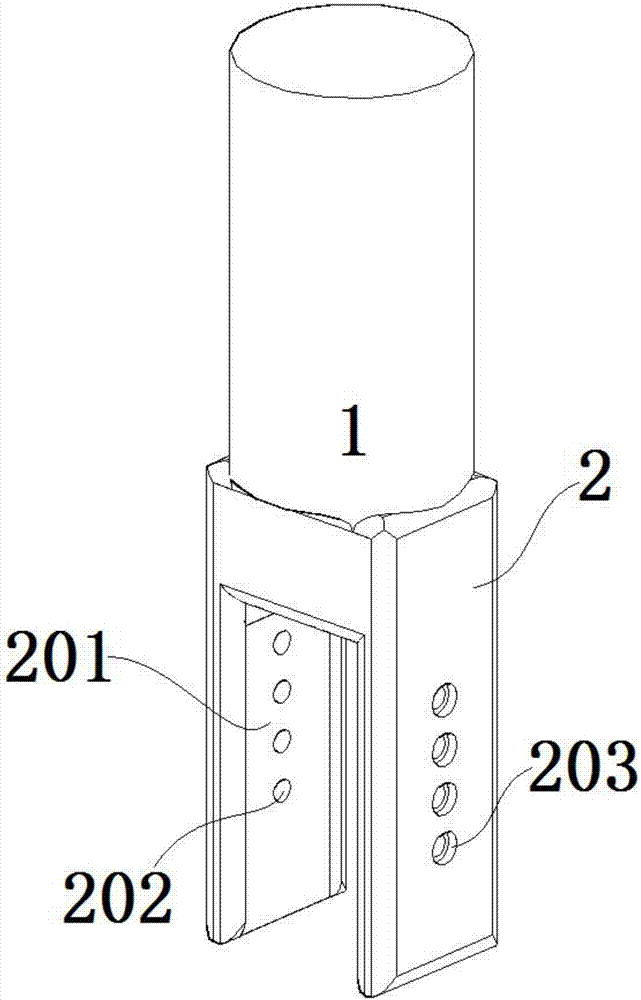

[0027] Please refer to the attached Figure 1-3 As shown, the present invention is a structure device for a pusher head of a flow-through farmland rice transplanter, comprising a pusher 1 of a rice transplanter, and the end side of the pusher 1 of a rice transplanter is a structure of a pusher head 2, and the pusher head 2 is equipped with a Seedling transplanting press plate 3 structure; push rod head 2 is a "U"-shaped structure; the "U"-shaped inner panel of the push rod head 2 is provided with a connecting plate groove 201 structure; the "U"-shaped two side panels of the push rod head 2 A plurality of adjustment through hole 202 structures are provided at equal intervals.

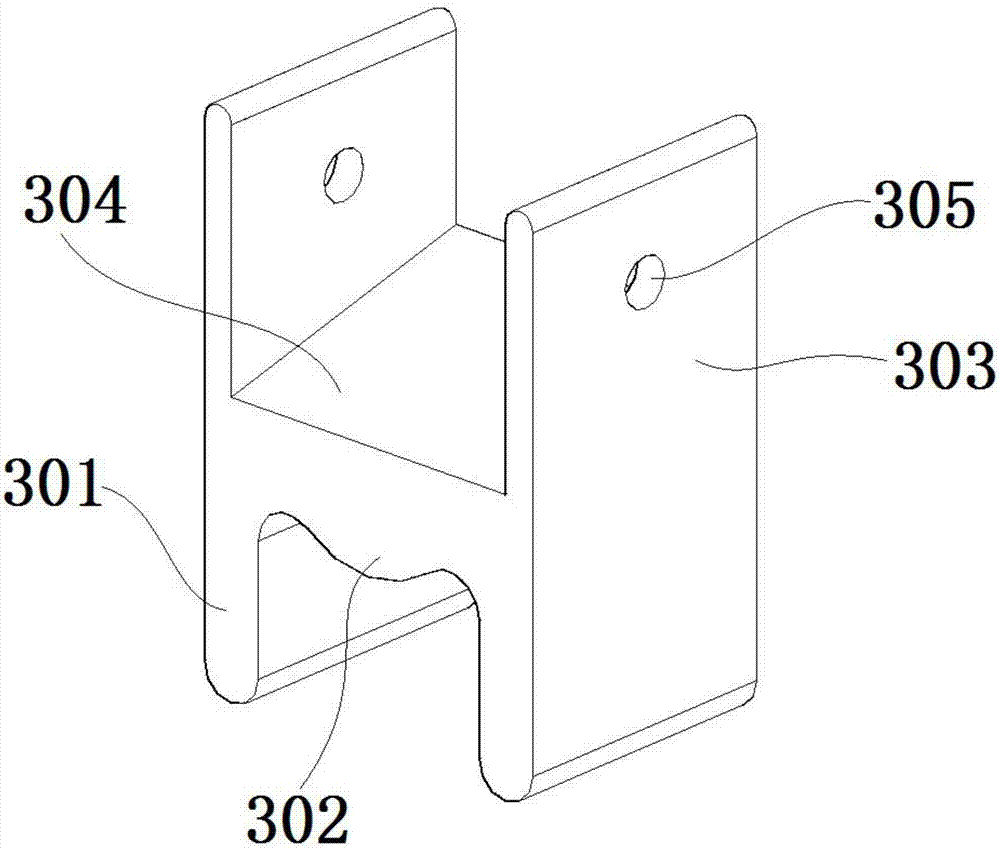

[0028] The seedling transplanting press plate 3 includes a press plate side connecting plate 301, a raised pressing block 302, a fixed connecting plate 303 and an overflow sloping plate 304; the raised pressing block 302 is fixed between a pair of pressing plate side connecting plates 301; the overflow s...

specific Embodiment 2

[0033] Using a rice transplanter to transplant rice seedlings in two fields with the same conditions, and analyze the floating rate of rice seedlings after rice transplanting, the following table data is obtained:

[0034] Table 1: Transplanting operation using the pusher head of a traditional rice transplanter

[0035] Planting area / mu

[0036] Table 2: Operation of using the pusher bar head of the present invention to move in and out of rice seedlings

[0037] Planting area / mu

[0038] From the analysis of Table 1 and Table 2, it can be concluded that the transplanting efficiency of the rice transplanter using the pusher head of the present invention is greatly improved, and the floating rate of the rice shoots is obviously reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com