Determination method of sbs content in sbs modified asphalt

A technology of modified asphalt and determination method, which is applied in the direction of removing a certain component and weighing, etc., can solve the problems of deviation, unsuitability for popularization, insufficient identification, etc., and achieves the effect of low cost and fast and convenient detection scheme.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The preparation method of the above-mentioned special separation solvent is as follows: stir the asphalt dissolved component and the balance component evenly, then add additives, and finally add the SBS protection component, and stir the mixture evenly.

[0061] In the present invention, the preparation method of the SBS modified asphalt sample sheet is as follows: heat and melt the SBS modified asphalt and pour it on a clean silicone rubber plate, and use a hot scraper to smear the modified asphalt when the modified asphalt has fluidity Form a film; after the modified asphalt is completely cooled, the modified asphalt film is peeled off from the silicone rubber plate and cut into rectangular sheets with scissors.

Embodiment 1

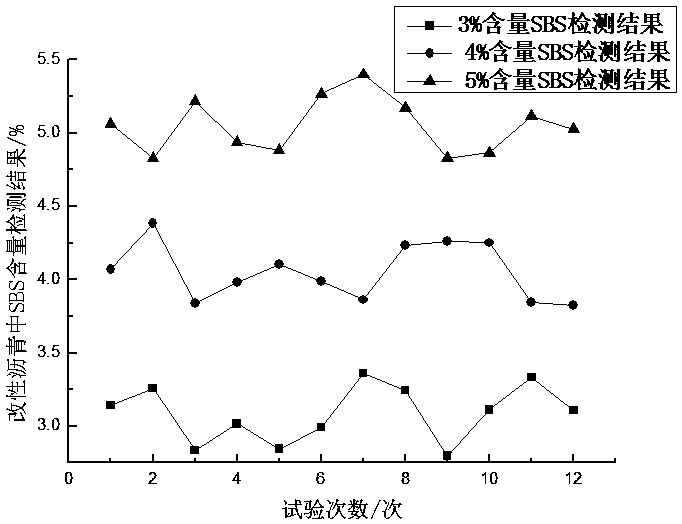

[0062] Embodiment 1: Determining the content of SBS modifier at a certain expressway construction site in Qinghai Province.

[0063] (1) Take 90# matrix asphalt and modifier SBS at the project site respectively, and prepare SBS with SBS content of 1%, 2%, 3%, 4%, and 5% according to the SBS modified asphalt configuration method of the expressway Modified asphalt samples;

[0064] (2) Calibrate the content of the SBS protective component in the special separating agent according to the following steps.

[0065] ①Heat the modified asphalt with 5% SBS content to 180°C, then pour the modified asphalt on the silicone rubber plate, apply the modified asphalt into a film with a hot scraper, and lift it off with tweezers after the modified asphalt is cooled , and then cut the modified asphalt film into 2cm×1cm slices with scissors;

[0066] ② Weigh 55 parts of kerosene and 3 parts of methyl acetate and stir evenly, add 10 parts of ethanol and 1 part of modified branched chain alcoho...

Embodiment 2

[0074] Embodiment 2: Determining the content of SBS modifier on a highway construction site in Shaanxi Province.

[0075] (1) Take 70# matrix asphalt and modifier SBS from the project site respectively, and prepare SBS with SBS content of 1%, 2%, 3%, 4%, and 5% according to the SBS modified asphalt configuration method of the expressway Modified asphalt samples;

[0076] (2) Calibrate the content of the SBS protective component in the special separating agent according to the following steps.

[0077] ①Heat the modified asphalt with 4% SBS content to 180°C, then pour the modified asphalt on the silicone rubber plate, apply the modified asphalt into a film with a hot scraper, and lift it off with tweezers after the modified asphalt is cooled , and then cut the modified asphalt film into 2cm×1cm slices with scissors;

[0078] ② Weigh 60 parts of toluene and 5 parts of ethyl acetate and stir evenly, add 15 parts of isopropanol and 1 part of fatty alcohol polyoxyethylene ether s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap