Creep-fatigue life prediction and reliability analysis method for Martensitic steel

A technology for fatigue life prediction and fatigue life, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as low prediction accuracy, high cost, and poor engineering applicability

Inactive Publication Date: 2017-11-24

SHANGHAI UNIVERSITY OF ELECTRIC POWER

View PDF3 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, under high-temperature and high-pressure environment, after repeated actions of unit start-stop and variable working conditions, this type of material will undergo creep-fatigue damage, which brings hidden dangers to the long-term safe and efficient operation of the generator set

[0004] In order to effectively evaluate the life of power plant furnace tubes, at present, the representative creep-fatigue life prediction methods mainly include the linear cumulative damage method, the ductility loss model, the strain range and strain energy division method, and the continuous damage mechanics model. Specific application conditions, when using, or need to determine more materi

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

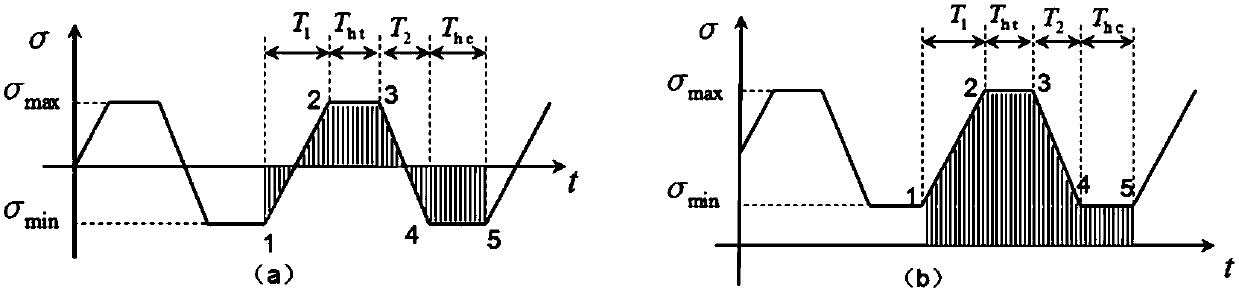

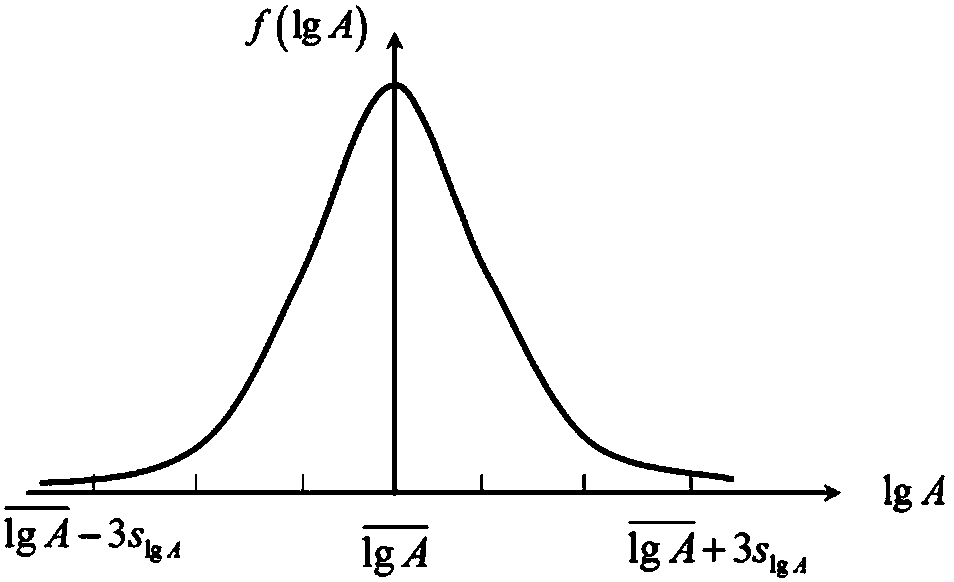

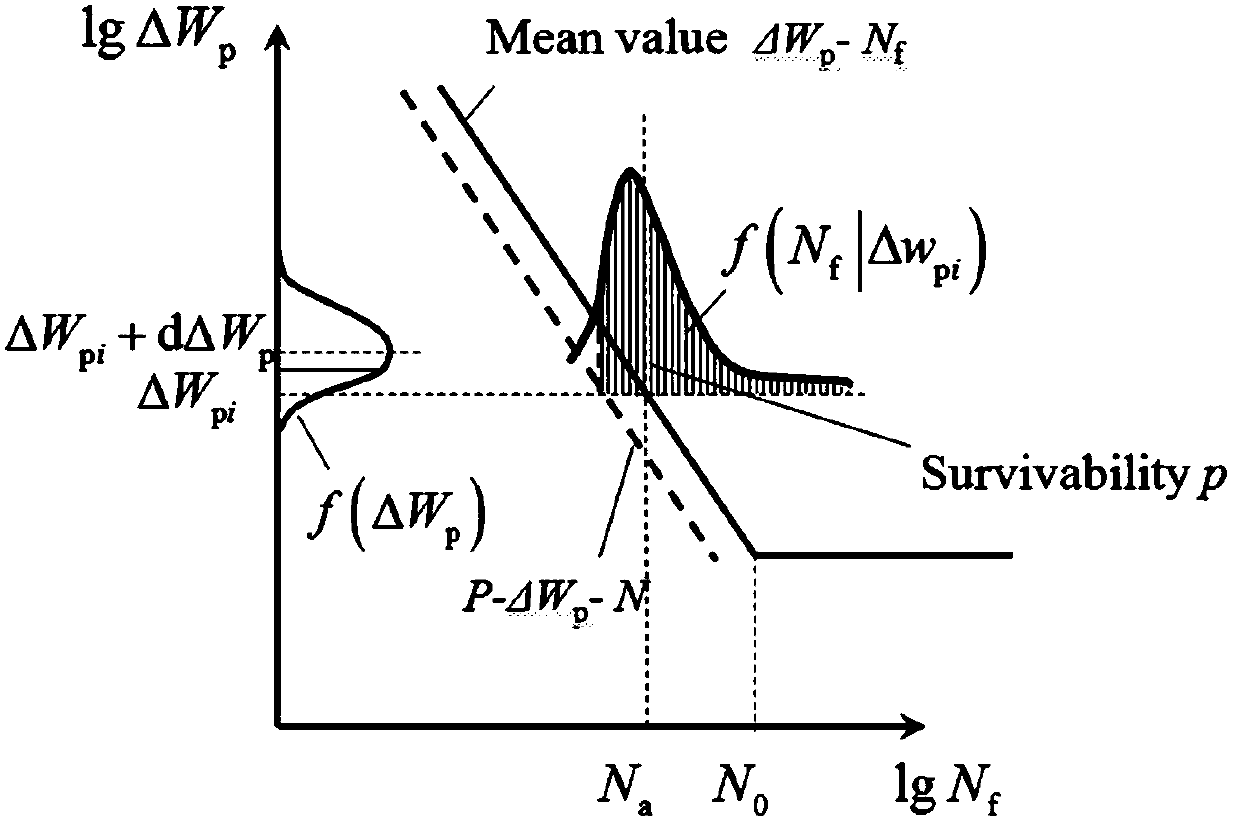

The invention relates to a creep-fatigue life prediction and reliability analysis method for Martensitic steel. According to the method, first, mechanical work density is defined; second, a creep-fatigue life prediction model based on the mechanical work density is derived, and the randomness of stress and life is considered; and last, a P-delta(W

)-N<f> curve of creep-fatigue life is proposed, and a creep-fatigue life reliability analysis model is given. Compared with the prior art, the method has the advantages that prediction is more accurate, and reliability is higher.

Description

technical field [0001] The invention relates to the safe operation technology of the pressure-bearing parts of the thermal power generating set, in particular to a creep-fatigue life prediction method and its reliability analysis method for 9-12% Cr martensitic steel used in power plant furnace tubes. Background technique [0002] In the 1980s, the Oak Ridge Laboratory (ORNL) of the United States took the lead in developing an improved 9Cr1Mo heat-resistant steel, which was later included in the American Society for Testing and Materials (ASTM) heat-resistant steel standard with the T91 / P91 grade. Good creep resistance; in the 1990s, Japan launched T92 / P92 heat-resistant steel on the basis of P91 by reducing the content of Mo, adding Nb, V, and controlling the content of B and N elements. Compared with P91 steel It has more excellent high-temperature creep rupture strength. At the same time, Europe developed a heat-resistant steel named E911; on the basis of German X20CrMoV1...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G06F19/00

CPCG16Z99/00

Inventor 纪冬梅任建兴郭恒超吴臻茂孙权戴晨

Owner SHANGHAI UNIVERSITY OF ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com