A fabric that absorbs odors

A technology for fabrics and odors, applied in the field of textile fabrics, can solve the problems of inability to remove odors, affecting users, and inconvenient frequent cleaning of large clothes, and achieve the effect of reducing cleaning frequency and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

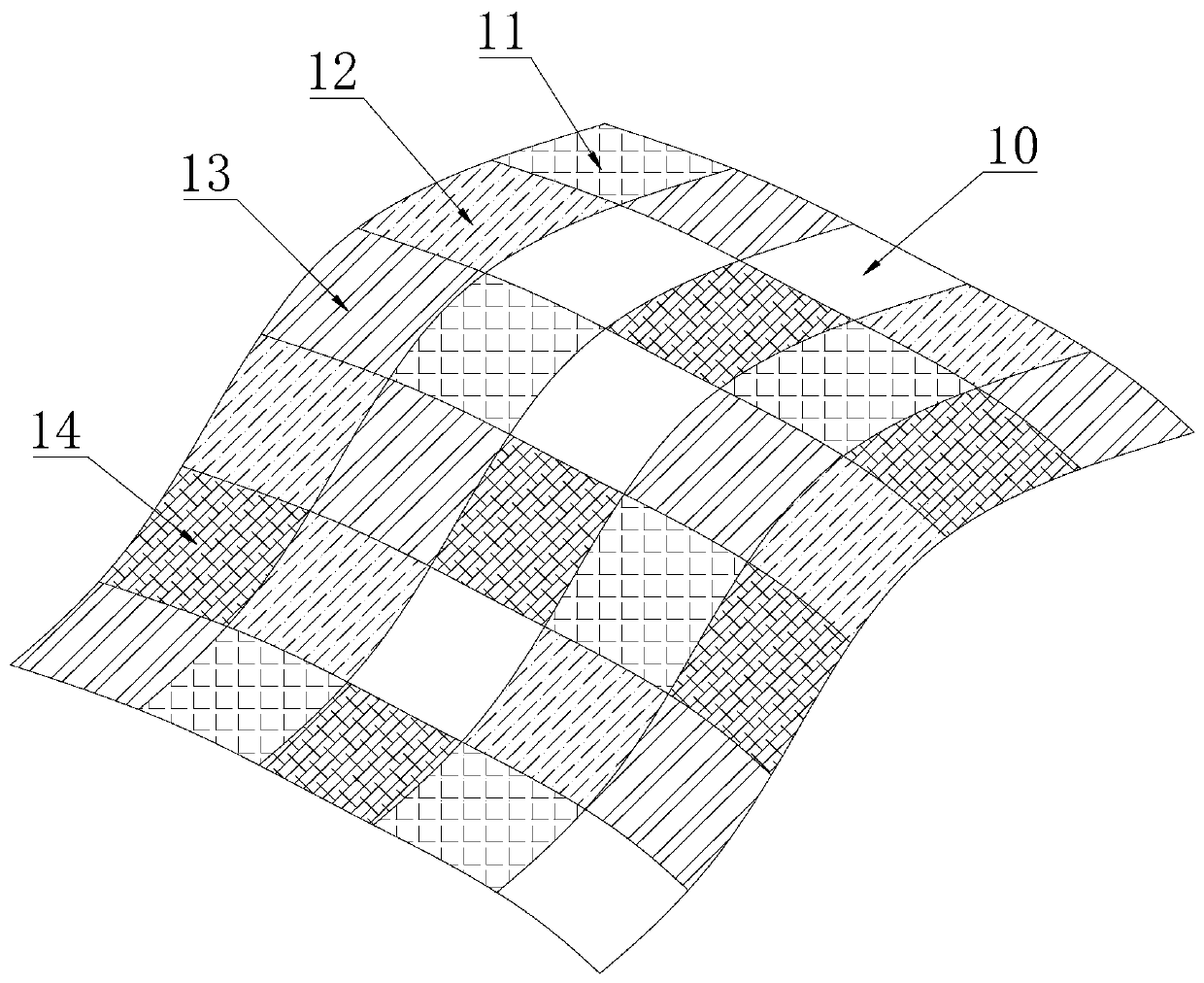

[0026] like figure 1 As shown, this embodiment provides a fabric capable of absorbing odors, including a base layer, the base layer includes a plurality of regions, part or all of the regions are provided with a coating layer, and the coating layer is composed of: activated carbon particles, Activated carbon fiber, coke, carbon black, photocatalyst, silicon dioxide, organically modified silicic acid, zinc oxide, talc, and silica gel are coated with any one or more ingredients; the coating of any adjacent area The composition of the materials in the cladding varies.

[0027] Preferably, on the same side of the base layer, a plurality of the regions are divided in a grid manner.

[0028] The coating layer is coated with any one or more of activated carbon particles, activated carbon fibers, coke, carbon black, photocatalyst, silicon dioxide, organically modified silicic acid, zinc oxide, talc, and silica gel. The material has good adsorption capacity, and it can be coated on v...

Embodiment 2

[0033] This embodiment is basically the same as Embodiment 1, the only difference is that a plurality of the regions are divided in a grid manner on both sides of the base layer. See attached figure 1 , the figure only shows the area distribution on one side of the fabric. In Embodiment 2, the other side of the fabric is also divided into multiple areas in a grid manner, and part or all of the areas are provided with the coating layer To achieve the function of absorbing odor. That is, areas are divided on both sides of the base layer to coat the recoating layer, so that both sides of the fabric have adsorption capacity at the same time.

[0034] Preferably, the areas on both sides of the base layer are arranged correspondingly, and the coating layers in the correspondingly arranged areas are coated with the same material. That is, the areas on both sides of the base layer are set correspondingly, and the materials of the coating layers in the corresponding areas are the sam...

Embodiment 3

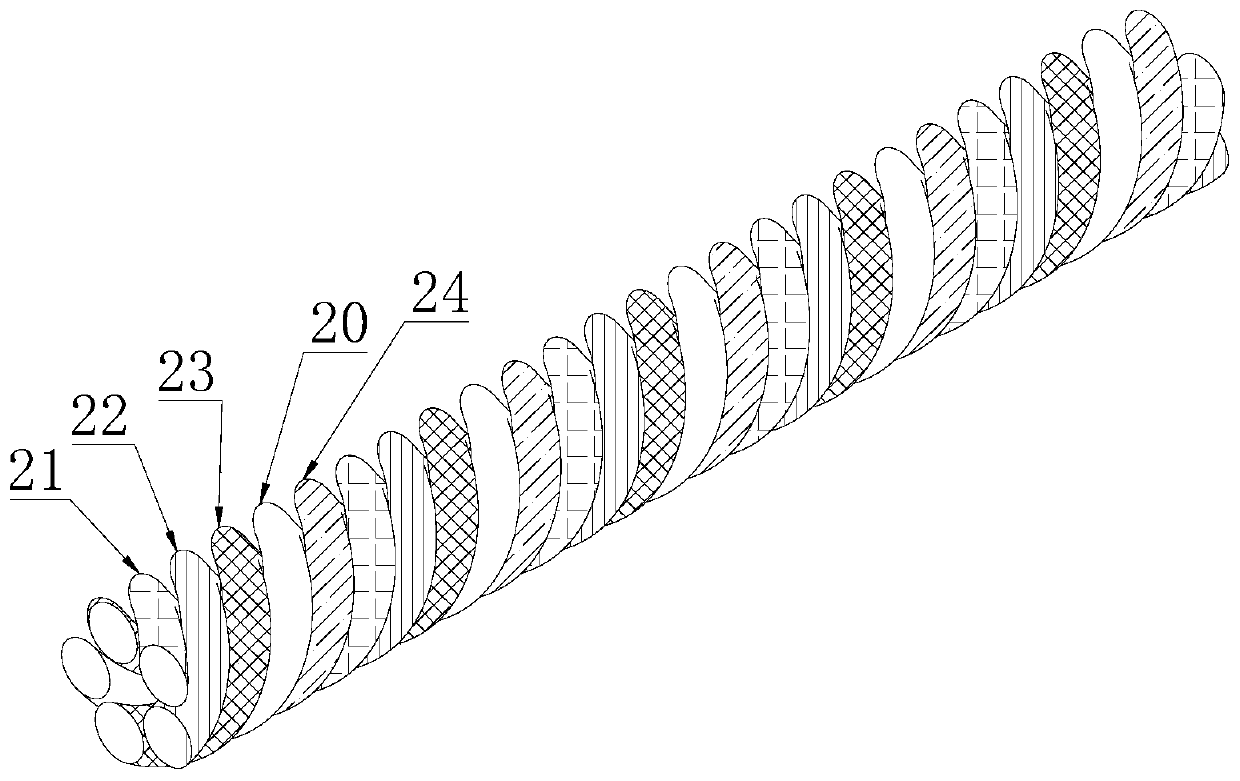

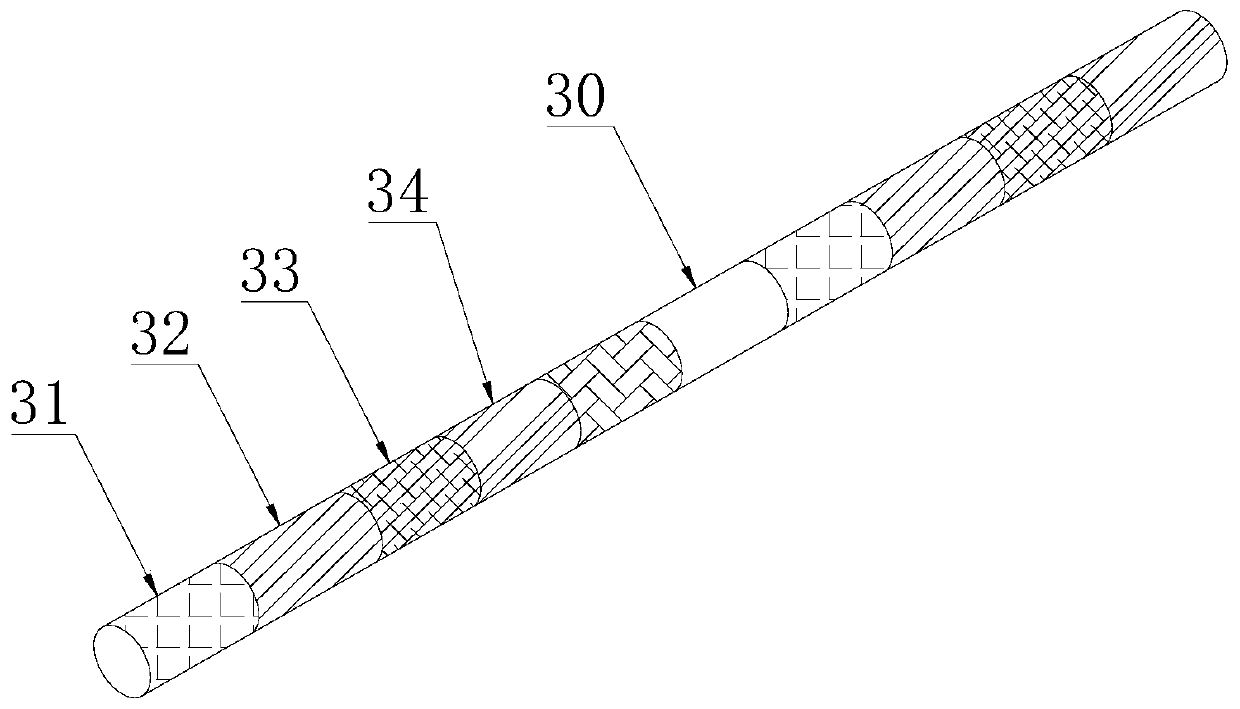

[0037] The difference between this embodiment and Embodiment 1 is that the area described in this embodiment is not divided into grids on the surface of the fabric; image 3 As shown, in this embodiment, the base layer is braided by the first wire, and the surface of the first wire is divided into a plurality of regions along the length direction of the first wire. That is, along the extension direction of the first wire, it is divided into: the first coating area 31, the second coating area 32, the third coating area 33, the fourth coating area 34, etc., and some areas can also be left uncoated. Cover, as a blank area 30. This structure has no requirement on the thickness of the wire, and the solution described in this embodiment can be applied regardless of the thickness of the wire. The surface and interior of the fabric produced by this solution have adsorption capacity, and no matter where the odor molecules adhere to the fabric, they can be adsorbed, and the fabric has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com