Mechanism for automatically mounting complete set of LED light bars

An LED light bar and automatic completion technology, applied in the field of mechanical installation, can solve problems such as low operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

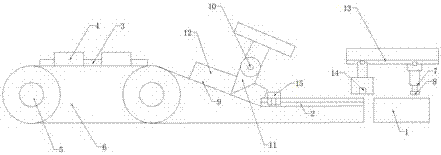

[0018] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

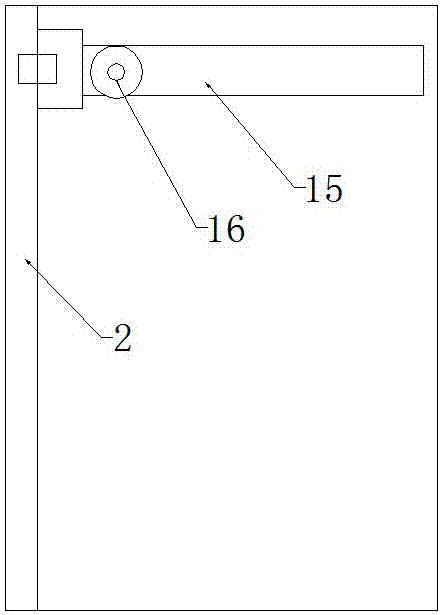

[0019] A mechanism for automatically completing the installation of a complete set of LED light strips 4, including: a conveyor belt 6 component that transmits the LED light strip 4 wrapped with a plastic film 3, a separation partition component that separates the LED light strip 4 from the plastic film 3, and receives the detached plastic film 3 The angle conversion component of the LED light bar 4 receives the angle-converted LED light bar 4 and places the workbench 1 of the installation frame, and the first guide rail 2 on the workbench 1 is connected to the first guide rail 2 and the LED light The bar 4 is sucked to the vacuum suction cup 14 above the mounting frame, connected to the first guide rail 2 and pressing the LED light bar 4 into the pressing assembly in the mounting frame.

[0020] The assembly of the conveyor belt 6 consis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com