Method for repairing the inner surface of a nuclear reactor shroud, shroud obtained by said method

A repair method and technology for nuclear reactors, which are applied in the field of maintenance of nuclear reactors and can solve problems such as inability to achieve weld volume inspection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

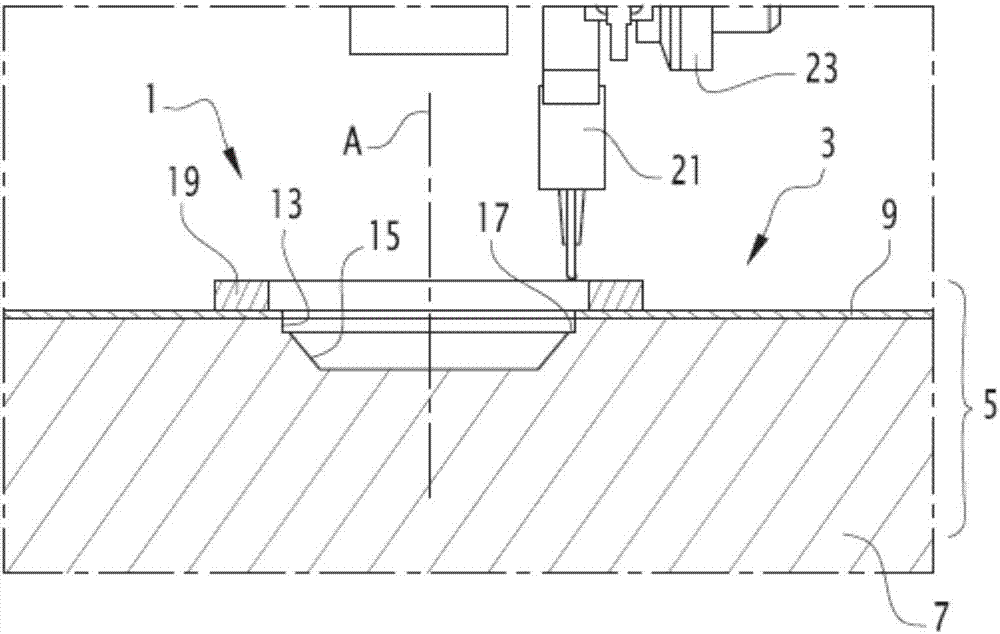

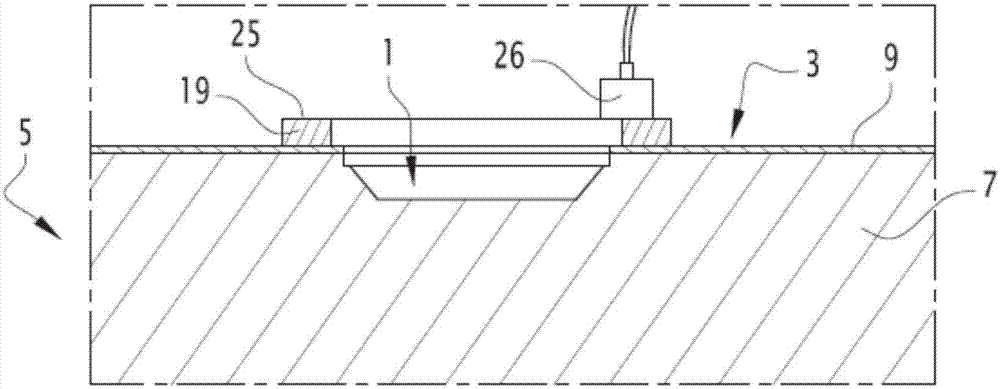

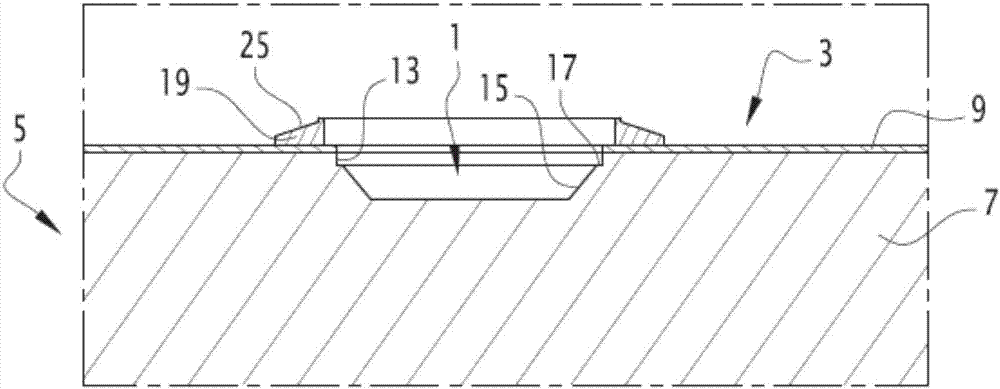

Method used

Image

Examples

Embodiment Construction

[0033] In one exemplary embodiment, the enclosure is a tank that houses a nuclear reactor core (ie, a nuclear fuel assembly). Hereinafter, it is designated by the acronym RPV (Reactor Pressure Vessel). In this case, the hood comprises a dome-shaped lower bottom carrying the trough bottom penetration. The groove bottom penetration structure is a hole arranged in the bottom of the dome-shaped groove, and a pipe body is arranged in a sealable manner in the hole, so that the measuring probe can be introduced into the groove and the detector can be removed from the groove. removed from the slot. These detectors enable measurements of neutron flow or temperature within the reactor core.

[0034] The tank also includes a tank cover with a plurality of holes in which a tap is sealably secured. These cocks allow passage of thermocouples or mechanisms for moving control rods.

[0035] According to another exemplary embodiment, said enclosure is part of a pressurizer and includes an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com